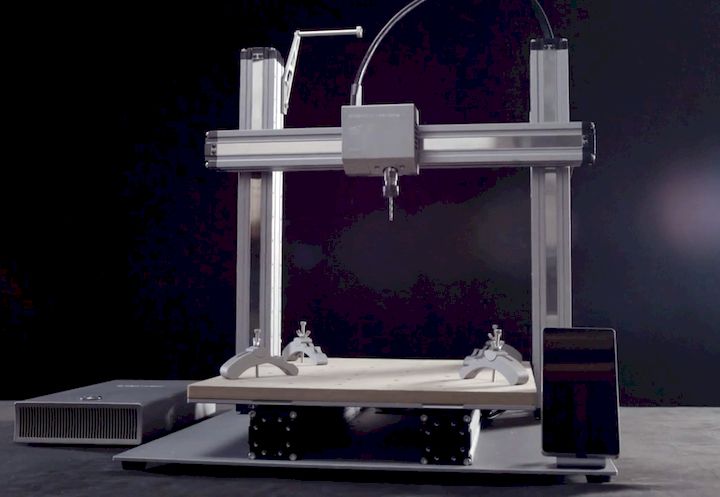

![The Snapmaker multi-tool 3D printer [Source: Kickstarter]](https://fabbaloo.com/wp-content/uploads/2020/05/snapmaker-2.0_img_5eb09792962ee.jpg)

Desktop multi-tool 3D printer manufacturer Snapmaker has raised an enormous amount of money for their new Snapmaker 2.0 device.

The China-based company is well-known for their first venture, Snapmaker “original”, which in 2017 raised a huge US$2.3M. This is quite notable, as 2017 was long past the early days of desktop 3D printer Kickstarters where several devices raised large amounts. To put this in perspective, Formlabs’ original Kickstarter campaign raised a then-record amount of US$2.9M.

At the time of Snapmaker’s first launch, we were a bit skeptical, having seen countless mismanaged desktop 3D printer launches, leaving consumer carnage worldwide. Many launches failed due to the number of orders — attracted by low pricing — that overwhelmed the companies’ manufacturing capacities.

Did that happen to Snapmaker’s first venture? Apparently not. They say they have fulfilled all 10,000 unit orders and an inspection of the feedback comments on their first Kickstarter campaign. Yes, there is the odd negative comment, but there is nothing there to suggest the company did anything other than deliver the goods. Multiple comments praised their new Snapmaker original.

Snapmaker 2.0: Modular 3-in-1 3D Printers

Snapmaker is raising funds for Snapmaker 2.0: Modular 3-in-1 3D Printers on Kickstarter! Unlock your full creative potential from 3D printing to laser engraving, cutting and CNC carving. Smarter, larger, and more powerful.

Now the company has introduced Snapmaker 2.0, an improved version but more or less the same concept: a desktop 3D printer with interchangeable toolheads to provide different functions.

The Snapmaker 2.0 includes the abilities for 3D printing, laser engraving & cutting, and CNC carving.

The 3D printing function is by filament extrusion, and they say the device is capable of handling most common materials like PLA and ABS, as well as the sometimes-tricky materials of wood-filled PLA and flexible filament. The nozzle is capable of 275C.

![The Snapmaker 2.0 multitool 3D printer comes in three models [Source: Kickstarter]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09792e8726.jpg)

The Snapmaker 2.0 comes in three different build volumes: the A150 is 160 x 145 x 160 mm, the A250 is 230 x 250 x 235 mm, and the large A350 is 320 x 350 x 330 mm, making it suitable for almost any desktop making activity. Each is supplied in kit form, allowing the price to be reduced considerably.

All three models sport an all-metal design, making the device quite rigid to reduce vibration. This is especially important for the CNC and laser functions, which are quite sensitive to motion.

There is a power monitoring function that will gracefully shut down operations if the power is out, and allow for resuming the job when power is returned.

The laser function utilizes a 1.6W laser. Having used laser cutters myself, I have to say this is a very small amount of power, and the results of cutting would be constrained somewhat. You will be able to engrave many materials, but slowly. Cutting materials would likely be limited to paper and similarly thin sheets.

Similarly, while the 12000rpm spindle on the CNC toolhead will indeed carve materials such as soft woods, acrylic, etc, the tool path will have to proceed more slowly than you would expect to see on a more powerful CNC machine.

What’s new on version 2.0 beyond the all-metal frame? There are a number of interesting improvements. First, there is now an automatic calibration routine to perform bed leveling. The filament is now monitored to pause the machine when an outage or break is detected. They’ve redesigned the hot end cooling system to be more effective, resulting in higher-quality prints.

For bed adhesion, they’ve added a spring steel flexible plate coated with an adhesive layer. This is pretty much a de facto standard on most machines these days, so it is good that Snapmaker added this feature.

For laser cutting, there is a camera that allows a preview of what you’re about to engrave (or cut). This is quite a good feature, as the rule I use when laser cutting is to always bring extra material to test with first. Previews will eliminate some types of testing. Also, a new grayscale linear mode is added to allow for far more rapid image engraving.

![Sample CNC carving from the Snapmaker 2.0 multitool 3D printer [Source: Kickstarter]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb097933afcd.jpg)

On the CNC system, a new collet system allows use of more than 100 standard bits in the Snapmaker 2.0. An MDF spoil board is included to protect the underlaying bed, but this should always have been used as this is standard CNC best practice. Now new users will immediately make use of that practice.

CNC milling by definition creates a huge amount of sawdust (or other kinds of dust, depending on the material). Cleaning up is always an issue, and Snapmaker has redesigned the frame slightly to allow for easier clean up. Eliminating dust is very important for 3D printing, as you don’t want to find dust in your prints!

They also list a number of optional components that can be added to the system, as well as hints of future new toolheads, like a rotary cutting system, for example.

![The Snapmaker 2.0 sports a handheld color touchscreen interface [Source: Kickstarter]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09793814b5.jpg)

A sophisticated software system is used to generate GCODE for the device, although they do say you can use third party tools. They also provide an android-powered movable touchscreen for operational control.

Like their previous model, the Snapmaker 2.0 models carry very low pricing:

EARLY BIRD / KICKSTARTER / MSRP

US$599 / US$719 / US$1200

US$749 / US$899 / US$1498

US$899 / US$1079 / US$1798

MODEL

A150

A250

A350

These are substantially good prices for a competent device like the Snapmaker 2.0, and given their track record, it is likely they will be able to deliver the device, unlike many other launch campaigns.

This combination of machine features, pricing and track record seem to have attracted the public in a big way. As of this publication, they have sold to over 4,100 backers, and are approaching an astonishing US$4.3M raised. This is likely the highest ever fundraising launch for a desktop 3D printer.

Via Kickstarter

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.