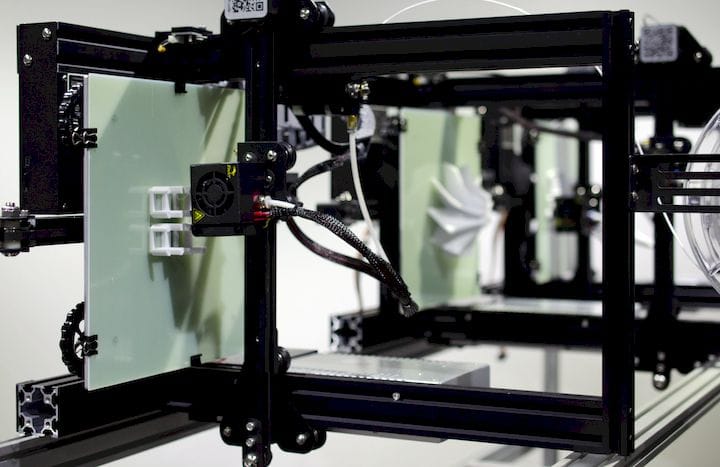

![The QPoD vertical 3D printing array [Source: 3DQue]](https://fabbaloo.com/wp-content/uploads/2020/05/3dque-sideways-printing-angle_img_5eb097563d0be.jpg)

This week we are going to see for the first time 3DQue’s revolutionary way to implement low-volume production using 3D printing.

The Vancouver-based startup, founded by Mateo Pekic, has devised a method of 3D printing that is quite different and could enable practical use of 3D printer arrays to produce larger quantities of 3D printed parts in parallel.

Five years ago, Pekic was a hobbyist working on 3D printing and providing a print service using his own equipment. He found that he could not keep up with requests because he spent far too much time manually operating the devices. He gradually started automating this labor, and eventually that work transformed into 3DQue, a new startup company.

We’ve seen several attempts at this in the past. Some involve simply tying together a series of 3D printers in a neat cabinet. But that doesn’t really solve the problem, because you must still manually operate each of the devices in the 3D printer array. This primarily means unloading completed prints, then redoing the print surface for the next job. The requirement for this manual labor mostly kills the benefit of using the devices.

What’s needed is an automation system to remove the prints and prep the print surface for the next job without human intervention. There are such things; we even had one of the first, the now-defunct MakerBot automated build platform. Since then there have been a few standalone 3D printers with a method of automatically removing prints, such as the Blackbelt conveyor belt system and more recently Tiertime’s continuous printing device.

But those are not arrays of machines; they are single machines. There’s only one large-scale implementation of continuous 3D printing we’re aware of, and that was Stratasys’ Continuous Build Demonstrator. This system involved an array of conventional 3D printers each equipped with a roll of build plate material. As prints completed, the roll would turn and be cut off, leaving a fresh surface for the next print job.

But that was shown two years ago, and we haven’t heard boo from Stratasys about the Continuous demonstrator ever since. It may be they’ve discontinued development of the concept.

![Part of the QPoD 3D continuous 3D printing system, with vertical print plates [Source: 3DQue]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb097566935f.jpg)

Enter 3DQue, who have developed a new form of print-removal. Their system is unique in that it has a specialized build plate that is oriented sideways. Prints are made at 90 degrees to the vertical — which does indeed work on many 3D printers, including 3DQue’s QPoD. When the job is completed, the print surface releases the print, and gravity lets it fall down into a container.

![The QSuite 3D printer console [Source: 3DQue]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0975691e96.jpg)

While that alone is quite interesting, what is more interesting is that 3DQue has built a sophisticated software system around the concept to enable true production operations using an array of such devices. Their software, called QSuite, is a fully end-to-end management system for production of parts using their hardware. They say it can efficiently control hundreds or even thousands of network-attached devices. The system intelligently dispatches work to available and compatible devices, and even re-routes work if failures are encountered.

![The QSuite 3D printer printing queue [Source: 3DQue]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09756b9614.jpg)

One question I had was regarding the completed prints. Such a system would be able to produce large quantities of parts, and how does one keep track of them? It turns out that 3DQue assures us that QSuite has some method of doing this.

Physically, the intention is to catch the completed parts with a sophisticated shuttle or conveyor system that could carry them to the next work station. However, this does not exist yet, and I suspect 3DQue may have to partner with an existing player in that space.

![This small part (left) was 3D printed 248 times in 8 days on the 3DQue system for use in a final product (right) [Source: 3DQue]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09756e0ffc.jpg)

The system does work. Their test system recently produced 248 parts by operating continuously without human intervention for eight straight days. Imagine what that kind of production could do for your operation.

![The QSuite 3D printer status dashboard [Source: 3DQue]](https://fabbaloo.com/wp-content/uploads/2020/05/3dque-Printers_img_5eb0975717474.jpg)

They expect to launch the full product in January 2020, but before then they will launch a beta-level product for clients to explore. This will be a 9-cell QPoD system, which by the way occupies only 10 square feet of space (1 square meter). They expect the pricing to be approximately US$45K, but there’s a pricing twist.

That twist is that they require US$1 per print hour, although they may tweak this in the future. This may seem like a burdensome cost, as I don’t believe any other vendor charges in that way, but there is a method here.

However, that price includes:

-

5-year equipment lease

-

On-site installation

-

1,000 hours of automation software (after the free hours, software charged at a starting price of US$1/hour, this decreases with volume)

-

1 year software upgrades & support

The intention of the QPoD/QSuite system is to produce parts continuously as a low-volume production system. The parts produced are no doubt to be sold to customers. 3DQue has worked through some financial scenarios and they believe — and we agree — that the total cost of running their system is still vastly below alternatives. This is mainly due to the fact there is almost no labor required to produce parts: the automation takes care of that. In other words, consider the per-print fee to be a replacement for the labor you’d otherwise pay for.

There are several ways forward for 3DQue. They could simply refine their system offering and sell it to clients. They could also, and are considering, licensing the technology to other 3D printer manufacturers who wish to get into the low-volume production business. Another possible course they might consider is configuring the technology into modern factory integration, where they may be able to scale up significantly.

At this point, however, they are to sell their beta-level system to the public, and we will soon find out whether their per-print hour fee is acceptable to low volume production operations.

For now you will be able to see this system in person if you’re attending the RAPID + TCT show next week. They intend on having a system up and running, producing parts on demand. In fact, you’ll be able to request a print and pick it up later. Get there early for that, as there may be a lineup!

Via 3DQue

A blog post reveals much of what happens behind the scenes at 3D print service Shapeways.