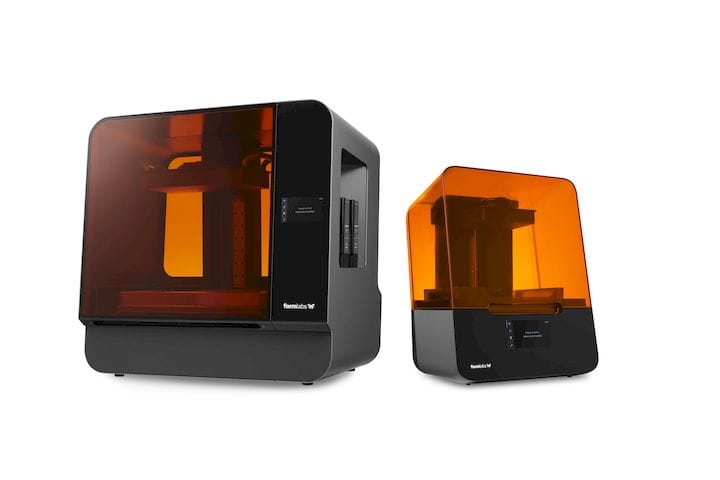

![The all new Form 3L and Form 3 resin 3D printers [Source: Formlabs]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09a0ac830c.jpg)

Formlabs has a secret no longer: they’ve released two versions of an entirely new 3D printer, the Form 3 and Form 3L.

The company began in 2013 with the Form 1, followed by the significantly more advanced Form 2 two years later in 2015. The Form 2 was so successful it allowed the company to attract very significant investment and expand across the globe. Inevitably, their new version would be named “3”, and it is.

![The massive Form 3L 3D printer [Source: Formlabs]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09a0b1ef82.jpg)

The Form 3 family, as it is comprised of basic and large-sized units, builds on all the expertise obtained from Form 1 and Form 2 designs. The key new feature resolves one of the nagging issues with the earlier devices, and one that is still present in many other resin-based 3D printers: fragility.

To understand this issue, a bit of explanation is required. The standard SLA process involves blasting a powerful laser beam through the bottom of a transparent tank of liquid resin. The laser frequency is tuned to the resin, and causes it to solidify. By moving the laser around, a complete layer can be built. But in virtually all SLA systems, this solidification also creates some adhesion with the bottom of the resin tank. To set up for the next layer, the current layer must be slowly “peeled” off the bottom of the tank, and allow fresh liquid resin to flow in. This can take considerable time, slowing the printing process.

But there’s another issue with “peeling”: if you happen to be 3D printing a spindly structure with certain geometries, it’s possible the peeling force exceeds the strength of the object, resulting in catastrophic failure. To overcome this operators might try 3D printing in different orientations, for example. Sometimes it is quite challenging.

The Form 3 family attempts to overcome this by changing to a new 3D printing process they call “Low Force Stereolithography”, or “LFS”. It’s not yet entirely clear how this works, but it does involve a flexible tank bottom. They explain:

“LFS 3D printing is an advanced form of stereolithography (SLA) that delivers consistently flawless parts. The LFS process uses a flexible tank to drastically reduce the forces of the peel process, providing incredible surface finish and detail, and linear illumination to deliver accurate, repeatable parts.”

There are a few other interesting aspects of LFS.

One is that the laser illumination is said to be “uniform”. Normally an SLA system uses mirrors to angle a beam to all portions of the build area. However, as the beam gets closer to the edge, the beam “spot” can become distorted by the angle of incidence, lowering print quality somewhat. Apparently the LFS system does not have this effect. It’s possible they’ve reconfigured the mirror system in an interesting way to achieve this feature.

Another interesting LFS feature is more advanced support structures. They say:

“Easy clean-up and smoother parts with tear-away light-touch supports.”

It’s not clear what this means, but it sounds like they have somehow designed a way to more gently attach supports for easier release. That is a very welcome improvement, as it is sometimes quite an effort to remove supports on some geometries.

There are also a number of features designed to transform the platform into a “production” system, capable of operating continuously over long periods. This could help move the machines into factories for low-volume production runs.

![3D prints made from the new Draft Resin [Source: Formlabs]](https://fabbaloo.com/wp-content/uploads/2020/05/form3-draft-resin_result_img_5eb09a0b64273.jpg)

Finally, there is a new material to be used on the devices: Draft Resin. This is something entirely new and not like anything I’ve heard of previously. It is a specialized resin that allows the machines to 3D print very thick layers up to 0.3mm, enabling much more rapid printing.

I suspect the Draft Resin was triggered by the large-volume Form 3L, which otherwise might take very long times to complete its prints if you leverage the entire build volume. It’s not clear if the Draft Resin can be used in either the earlier Form 1 or 2 models. [UPDATE: Yes, Formlabs now informs us that Draft Resin is now available for the Form 2.]

Now for the details, as we know so far:

![The Form 3 desktop 3D printer [Source: Formlabs]](https://fabbaloo.com/wp-content/uploads/2020/05/form3-machine_result_img_5eb09a0bb2565.jpg)

The Form 3 will have a build volume of 145 x 145 x 185 mm, slightly taller than the Form 2, but with the same X-Y dimensions. The device will be sold in a basic configuration for US$3,499, and a “Complete Package” for US$5,999 that bundles in a Form Wash and Form Cure post-processing devices, as well as an extended warranty. Both will start shipping this June, only a few months away.

![The huge Form 3L 3D printer [Source: Formlabs]](https://fabbaloo.com/wp-content/uploads/2020/05/form3L-large_result_img_5eb09a0c060a3.jpg)

The much larger Form 3L has a massive build volume of 200 x 335 x 300 mm, and is clearly being targeted for production applications. There’s only one offering for the Form 3L, priced at US$9,999 and you’ll have to purchase the Form Cure and Form Wash separately. I’m thinking those devices might be too small for the Form 3L, however, so it may be that Formlabs could announce larger versions in the future. Nevertheless, the Form 3L is set to ship towards Q4 of this year.

We did ask about the current Form 2 device to find out what will happen to it. Some companies abruptly terminate older devices when a new version is released. That doesn’t seem to be the case here, as Formlabs tells us they intend on continuing the market the popular device, and will lower the pricing. The basic Form 2 will be priced at US$2,850, and the “complete package” with wash and cure stations will be priced at US$4,499, both US$500 less than their original pricing.

I’m quite excited about the Form 3 family, as these devices should definitely be significantly improved over the already-good Form 2 machines. Formlabs as a company has a habit of learning and improving, as we noted when first testing the Form 2. Their reputation suggests we should see similar dramatic improvements on the Form 3.

Via Formlabs

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.