![Part of the BIQU Thunder desktop 3D printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09b75599f8.jpg)

We had a chance to test an interesting 3D sprinter and software combination: the BIQU Thunder and MyMiniFactory’s new app.

This is a three-part series, with part 1 and part 2 focusing on the BIQU machine and part 3 focusing on the MyMiniFactory app.

![Starting a print on the BIQU Thunder desktop 3D printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09b75cb796.jpg)

Once I managed to get everything together, I began 3D printing, and found the results to be quite good. At times the print quality rivaled our Prusa. Here you can see a comparison 3D print of the Super Stress Test, where it seems to even look better than the Prusa’s version.

![Comparing 3D print quality; on the left is the BIQU Thunder print of the Super Stress Test, and on the right is the same from a Prusa MK2.5S [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09b762ed23.jpg)

Printing operations mostly proceeded smoothly, but then this happened:

![Error message [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/biqu-abnormal-128229_result_img_5eb09b766e34c.jpg)

One issue I encountered was that during longer prints was a transitory failure of extrusion. Sometimes I would see the print process halted, and an ambiguous “Abnormal Extrusion” message on the touchscreen. Eventually I realized there must have been something amiss with the filament-out sensor.

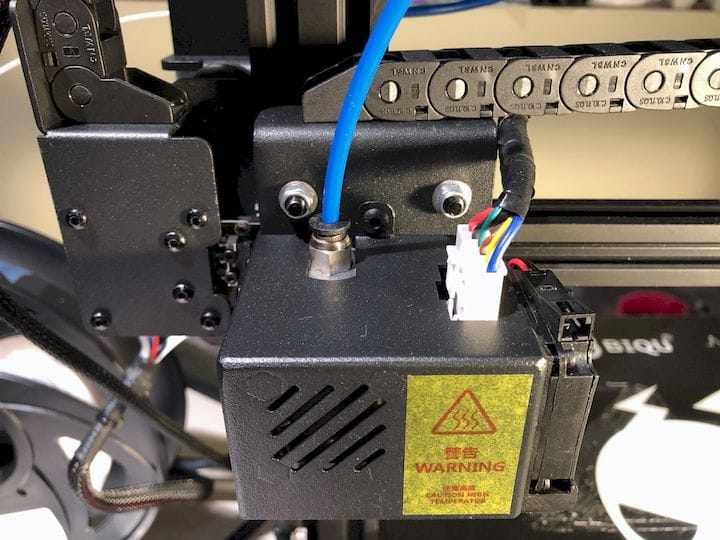

![Part of the BIQU Thunder desktop 3D printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09b76ace4d.jpg)

We contacted BIQU for advice on this issue and they suggested, via a cryptic video, that we should adjust a bolt that would tighten the grip on the filament as it passes through the extruder. Unfortunately, we seem to not have any such bolt installed on the extruder!

![Tighten the bolt, but there’s no bolt [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09b7705a6c.jpg)

BIQU was quite surprised about this, as they have a comprehensive (apparently “72 hour”!) testing and quality program. But they said they could send out any replacements if required.

However, I managed to find a bolt that fit so that wasn’t necessary. Unfortunately, the presence of the bolt had no effect on the “abnormal extrusion” issue that reoccured often. In the end I simply disabled the filament sensor and from then on all 3D printing operations proceeded very smoothly. Since then I’ve found evidence in other forums that other people are experiencing similar problems with their BIQU Thunder, and that disabling the filament sensor does solve the problem.

The BIQU is equipped with some very interesting features. One feature I particularly liked was the automated power shutdown that happens when the machine finishes a print. This means that overnight prints don’t require the power to be left on for many hours. However, there is something unusual that happens because of this feature: The automated power shutdown does not flip the power switch, so in the morning you will find the machine powered down but the power switch is still in the on position. To re-power on the machine you must flip the switch off and then on again.

![Turning it off then on again [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09b774ef72.jpg)

I also found the power switch to be in an unusual location. It’s positioned underneath the print surface on the control box. To access it you must first slide the print service to the back to reveal the power switch.

Another very useful feature is the ability to recover from an unexpected power cutoff. If the power is lost the machine retains information about the current state of the print and it’s able to resume printing at that point when you restore the power. This could be a life saver if you’re printing a large object, which would often be done on this large machine.

The BIQU Thunder operates relatively quietly except for one aspect: the main cooling fan for the electronics unit. It’s actually quite loud and blows continuously throughout operations. However, you get used to it after a while.

Overall, the BIQU thunder is a pretty decent machine. The additional features place it a step above the typical bare-bones machines at this price range. And what is that price? From MyMiniFactory it’s priced at only US$579, which is a very good price for a machine of this size and including these features.

This is a three-part series, with part 1 and part 2 focusing on the BIQU machine and part 3 focusing on the MyMiniFactory app.

Via BIQU and MyMiniFactory

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.