![Chart of Sunata’s new GPU capabilities [Source: Atlas 3D]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09e05aab89.jpg)

Atlas 3D’s Sunata tool is now GPU enabled.

We’ve covered the startup company previously, but for those unfamiliar, Sunata is a CAD tool that can provide very useful answers to optimization problems during design of metal 3D prints.

The software works by specifying some objectives for the print, such as minimizing print time, minimizing support removal efforts or even minimizing object distortion. It then uses a very sophisticated thermal modeling system to simulate how the the print would execute, and recommends optimal parameters for the print, including print orientation and support structures.

This is critically important for metal 3D printing, as that discipline involves use of very expensive equipment and materials. Getting a print wrong isn’t just a matter of delay; it’s a matter of great financial importance. Sunata can help avoid such scenarios.

But performing a simulation is quite costly in terms of processing power. The original release of Sunata would provide the best answers, but at the cost of considerable CPU time.

Now the company has short circuited that problem by developing and releasing a version of Sunata that leverages GPU capabilities.

GPUs, or Graphical Processing Units, are the engines in your computer’s video card. These are ostensibly designed to handle the countless calculations related to video processing, and in particular 3D view preparation. These calculations are very numerous (for every screen pixel) and frequent (for every split second the display changes).

Thus a proper GPU contains arrays of processing elements.

Normally GPUs do just that — process graphic requirements for the computer. However, with appropriate APIs it is also possible to repurpose them for other uses, particularly if there is no immediate need for heavy graphics processing. That’s what Sunata is doing here: they are making the video card do the work that the otherwise overloaded CPU would do.

What is the result? Atlas 3D says that the resulting computations are sometimes 20X faster than by using the basic CPU of your computer.

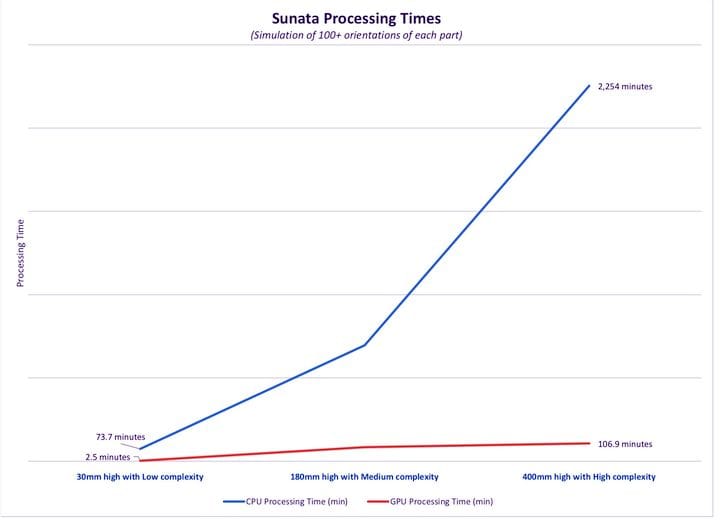

In the graph at top you can see the effect in some detail. The chart shows two lines, one (blue) representing the processing time required when using a single CPU, and the other (orange) line representing the time required when work is dispatched to the GPU.

Three examples appear in the chart: 30mm object with low complexity; 180mm object with medium complexity and 400mm object with high complexity. As you can see, the single CPU’s resource needs grow almost exponentially as the complexity and size rise. However, when using the GPU the elapsed processing time is mostly the same, regardless of the complexity or size of object.

This is likely because the GPU is a parallel device with tons of smaller processing units. For simple simulations only a few GPU elements are used; for more complex analyses Sunata simply dispatches more from the pool of GPU elements. I suppose at some point you might run out of GPU elements and elapsed time would start to rise dramatically, but it’s likely for most analyses you’d simply enjoy much faster results.

If you’re processing metal 3D prints, you might want to check out Atlas 3D’s Sunata tool.

Via Atlas 3D

MiniFactory’s new software produces a very useful report for each 3D print that may be important for clients. We had a close look at one.