![Our 2018 annual reader survey showed changes in our audience [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09de061fdf.jpg)

We’ve completed our annual reader survey and found some interesting results that we’d like to show you.

Each year we execute a simple online survey to find out more about you, and what you’d like to see in our publication. This year, as always, we received many very interesting suggestions that we will be implementing soon.

Part of the survey is to find out more about our readers, and there were several interesting findings. Let’s review them.

Our readers appear to be of all ages. The survey listed a few age categories, and we basically have about equal numbers in all of them. In the past we skewed slightly older in reader age, but this is changing. Clearly, age is no barrier to 3D printing.

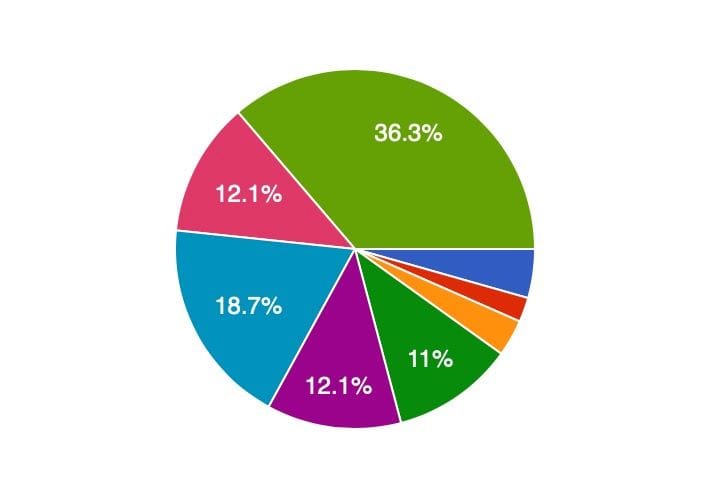

Almost 40% of our readers have more than 5 years of experience with 3D printing, which is significant. Almost 80% of our readers have more than 2 years of experience using 3D printing, so you folks are a very technologically mature audience. And we’d like to shout out to the 18% who have been reading us for more than 5 years!

The percentage of women reading Fabbaloo has increased again, now tracking well above 14 percent. This is a very substantial increase since our 2016 survey, where we saw only 3.6% of respondents identify as women. We’re very happy to see this increase, as it indicates many more people are bringing their talents to the world of 3D printing.

The types of readers are mostly unchanged with a little over half identifying as “Professionals using 3D printing”, and about a third as “DIY 3D printer enthusiasts”. What’s surprising is that the percentage identifying as “Consumers interested in 3D printing” has increased, and increased substantially, now at almost 10%, whereas two years ago it was only about 5%.

What does this mean for consumer-based 3D printing? The corporate push into the consumer space with 3D printing pretty much evaporated four years ago, tanking a number of 3D printing stocks at the same time. Since then the market has shifted profoundly to professionals. I’m now wondering whether the concept of 3D printing has become so solidified in the minds of consumers that it might be time once again to attempt developing a true consumer 3D printing product.

Most of our readers are involved in prototyping and manufacturing, as you might expect, with significant percentages reporting they’re in the automotive, aerospace and research areas. Surprisingly, only 12% report using 3D printing in the dental industry. I’m a bit taken aback by this stat, as there have been countless new dental-focused 3D printing solutions marketed over the past few years. Could this mean that 3D printing is still having issues entering the vast dental market? Maybe that’s why companies like Formlabs and others have strongly focused on it, as it may be an open market for the taking?

Readers seem to like our coverage of 3D print research, news events and our analyses. Surprisingly, one of the less popular story types was our intermittent “funny” stories. We truly enjoy writing them and will continue to do so. If you haven’t seen them, you might want check out this, this, this, and this. Hmm, April 1st isn’t that far away…

A large majority of our readers (72%) operate their own 3D printers, with another 14% have “access to a 3D printer”. Surprisingly, only 5.5% use a 3D print service. This is quite surprising, as 3D print services are a fantastic way to gain access to equipment you don’t have or don’t have the ability to operate. I’m beginning to think people have a bias for using “their own equipment” and incorrectly discount the value of using services.

Regarding materials, it seems that our readers are mostly plastic-heads, although a surprising 55% also use metal 3D printing, even though it is significantly more expensive to do. I’m also surprised that 20% of our readers are into bioprinting.

We asked which materials would be used “more” in 2019, and, again, unsurprisingly PLA is the winner, with 60% saying they’re going to use even more of the inexpensive material. I think cash is king when it comes to materials. PETG edges out ABS, so it may be that the venerable original filament material, ABS, may be on the way out.

Thirty percent will be using more flexible materials, and there were notable percentages on all of the high-temperature engineering materials like PEEK, PAEK, ULTEM, etc.

Over 20% say they will be using more nylon powder, suggesting that the recent availability of low-cost SLS systems may be driving up the usage of this type of material. Again, cash may be king.

One thing that came up many times in the comments was readers thanking us for our unbiased coverage of the 3D printing industry. That’s one of our key operating principles, and I’m very happy to say we’re continuing with that approach going forward.

Finally, the survey had a bit of encouragement with a prize to be awarded to a lucky random respondent. I can say that the winner has been selected and contacted, so if you haven’t heard about your entry yet, it wasn’t you.

We’re looking forward to improving greatly in 2019 and doing next year’s survey!

Fabbaloo is up and running with our full operations team once again.