![The new Pro 3 3D printer [Source: FELIXprinters]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09ea747758.jpg)

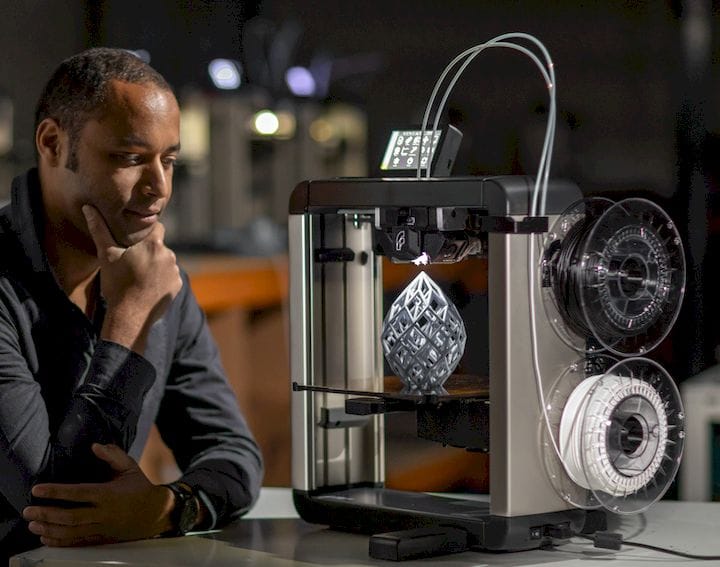

FELIXprinters announced their latest professional 3D printer, the Pro 3.

The Netherlands-based company is one of the older manufacturers of 3D printers, having been founded in 2011 by Guillaume Feliksdal and his father. Feliksdal was inspired by a poor experience with a typical RepRap 3D printer kit of that day, and sought to build a better machine.

Since then FELIXprinters has been gradually issuing increasingly more powerful, reliable and quality 3D printers year after year, following in the footsteps of their initial FELIX 1.0 3D printer.

![Excellent quality 3D prints from the Pro 3; note flexible build surface [Source: FELIXprinters]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09ea77916c.jpg)

The new Pro 3 includes all their learnings from prior equipment, such as automated calibration, filament-out sensing, and quick swap extruders. They also include their very interesting “swing” extruder that allows the unused hot end from the dual extruders to be swung out of the way so that collisions don’t occur.

![The swing extruder on the Pro 3 - note different elevation of the nozzle tips [Source: FELIXprinters]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09ea7a86b5.jpg)

The build volume of the Pro 3 is a generous 235 x 244 x 235 mm, and their standard nozzle is 0.35mm in diameter, allowing for crisp 3D prints down to 0.05mm layer size. The build plate is now a magnetically attached steel flexplate, as seems to becoming the industry standard approach.

![The magic touchscreen on the Pro 3 [Source: FELIXprinters]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09ea7d4888.jpg)

The most notable change is the addition of a powerful color touchscreen and computing capability within the machine. FELIXprinters says the touchscreen gives “super powers”; while they’re not quite super powers, the functions are quite useful.

The touchscreen performs all the usual and expected printer controls but also allows for remote print monitoring automatically without the need for an external set-top box. It can also store print files for repeat prints, and be used in a multi-user environment.

But what’s really interesting is that the touchscreen can also act as a controller for other FELIX 3D printers on the network. This allows the machines to become a “print farm” where work is dispatched to idle devices.

Why I believe this is interesting is because it is the same approach used by Ultimaker on their Ultimaker 3 device: a way to get larger quantities of 3D printers into businesses that need to bypass the “IT Department”. Normally the creation of a print farm would require installation of servers, etc., that would involve IT specialists, sometimes delaying the process or making it expensive for departments. But with this development, one could simply buy a bunch of FELIX 3D printers and voilà – you have a print farm with no fuss.

It’s a very attractive notion that I suspect more professional 3D printer manufacturers will catch on to in short order.

Meanwhile, you can pre-order a new FELIX Pro 3 for delivery in February. Pricing is set at €2,799 (US$3,200) for the full touchscreen model; for a Pro 3 without the fancy touchscreen the price drops to €2,450 (US$2,800).

Via FELIXprinters

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.