![E3D-Online’s tool-changing 3D printer [Source: E3D-Online]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09dd924c8a.jpg)

E3D-Online has nearly completed its beta test of an unusual tool-changing 3D printer.

The UK-based company is most well known for their powerful and reliable hot ends and extruders, which are used in countless 3D printers made by dozens of manufacturers worldwide. But they’re also working on an advanced 3D printer.

Their “tool-changing” 3D printer is very unusual in its approach to achieving multi-color / multi-material prints. While most current concepts involve using multiple print heads in a fixed line on the 3D printer’s motion system or some form of single-nozzle-but-multiple-input-feeds system, E3D’s concept is very different and it overcomes the problems with these approaches:

-

Multiple hot ends can interfere with each other, and require very careful alignment to avoid print catastrophes and poor output.

-

Single-nozzle approaches require “purge” cycles to get rid of the previous color, wasting both material and considerable time.

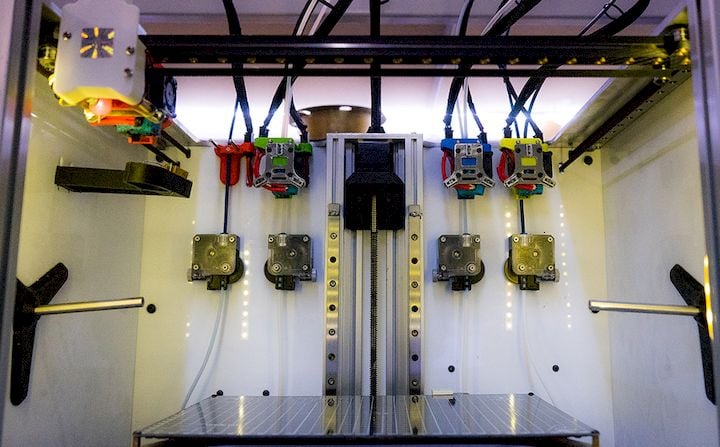

E3D’s approach is to literally use multiple Bowden extruder/hotends, each used singly by the motion platform. The idea is to keep these ready for immediate use, and have the motion system stop by to “pick them up” and extrude. This allows a very quick method to swap materials/colors without much delay, and no requirement for purging or alignment issues.

Their current approach is a system involving four different hotends, thus up to four different colors — or materials — can be 3D printed in the same print job.

![The four stations for the tool-changing 3D printer [Source: E3D-Online]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09dd9993d8.jpg)

If that description doesn’t make sense, then you might want to watch this video, from one of E3D’s beta testers, that shows how the system works when changing tools:

Here’s an example of what you can achieve with this system from one of their competent beta testers, “Adalinda: The Singing Serpent” modeled by @Loubie_3D and printed by René Jurack. Apparently this 250mm tall item required no fewer than 2,807 tool changes during the print to achieve the multiple colors. E3D says these changes cost only about 5% of the total print duration, which is very good.

![A beautiful multi-color 3D print made with a tool-changing 3D printer [Source: E3D-Online]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09dd9df91d.jpg)

You’ll also note the very high quality of the print; color switches are very crisp as there is no residual “other” material to deal with — each hotend is “pure”.

E3D’s approach is to continue with their beta testing until March 1st, after which they will collate and analyze all the feedback. They will no doubt develop some changes to the system at that point, and proceed on with producing the final product.

That final product is actually a kit that you will assemble. They’re providing a set of parts that can be built into a fully operating, tool-changing, four-extruder 3D printer. The cost of the kit is set at £2,600.50 (US$3400) and I’m not sure what the £0.50 is for.

Via E3D-Online

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.