![The BlackBelt continuous 3D printer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a17e51e8e.jpg)

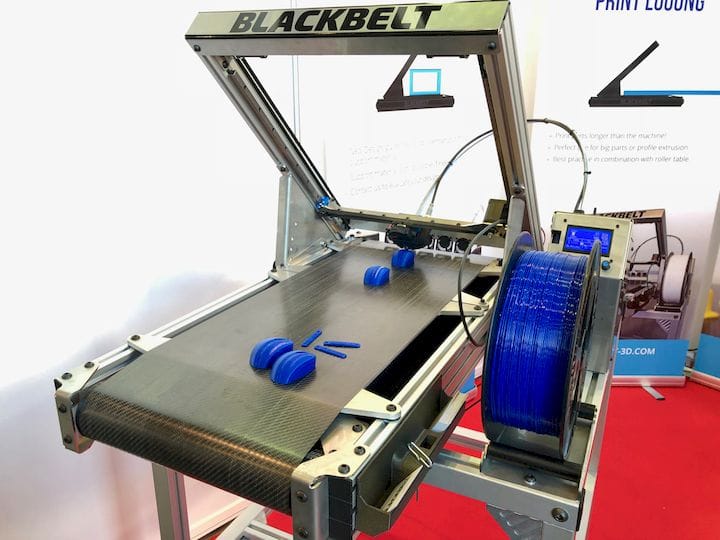

We learned more about the highly unusual BlackBelt 3D printer.

If you haven’t heard about this machine, you’ve missed one of the biggest innovations in desktop 3D printing since its inception in 2009. The machine’s unique mechanical design allows it to 3D print continuously – and have some interesting and beneficial side effects.

The two main features of the BlackBelt system are the tipped extrusion system, which is angled at 45 degrees to the print bed, and the print bed itself, which is actually a carbon fiber conveyor belt.

Objects are printed on the belt, which acts as the Z-axis. However, instead of providing an “up and down” motion, the belt provides a horizontal motion. There are still three axes of motion in the BlackBelt system; they’re just different from the more common Cartesian design.

The resulting prints often have superior surface quality because the terracing effect frequently seen on near-flat surfaces doesn’t happen when the print takes place from an angle.

The machine is able to 3D print in PLA, PETG and colorFabb’s NGEN materials, but we understand the company is working on a way to print ABS material through an adhesion solution.

This angled extrusion has an interesting side effect: support structures are different because the angled extrusion is naturally supported in a different direction. This means that it is entirely possible to 3D print objects having certain geometries without any support structures, such as this simulated mouse.

![An “impossible” 3D print made on the BlackBelt machine. Note the long gap that runs under almost all of the top of the mouse [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/blackbelt-print2-1_result_img_5eb0a17eb120c.jpg)

Note the near impossibility of 3D printing this item on standard filament extrusion machines. Even with support structures, this object would be impractical to 3D print as you would likely not be able to actually remove the supports that would be deeply embedded within the object.

We understand that the longest model printed on the BlackBelt system is 2m in length, but I suspect one could make even larger parts if enough material and a method of supporting the extended part during printing were arranged.

We learned that the inventor of the BlackBelt system was in fact working at colorFabb, a notable developer of advanced 3D printing materials in the Netherlands. Apparently during his tenure at colorFabb the company received an enquiry asking how one could 3D print a very large number of objects efficiently.

At the time, colorFabb – or anyone else for that matter – didn’t have a good answer to that question. But that inspired the development of the BlackBelt system in the inventor’s off-hours from colorFabb.

Since then the development evolved into a real product, which was launched in 2017.

Today the product is marketed by BlackBelt 3D RV, an independent company that happens to have the same address as colorFabb, as the two companies work very closely together. Assembly of the machine is actually outsourced to an external manufacturer.

So far the company has sold something near 60 units to the public, priced at approximately €10,000 (US$11,400) each.

I’m wondering why this approach to 3D printing hasn’t been more popular, as it does seem to offer significant advantages without much difference in machine build cost.

Via BlackBelt 3D

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.