![Materials Solutions’ new additive manufacturing facility in Worcester, UK [Image: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a0ace6614.jpg)

The additive manufacturing vision at Siemens is for a cross-industry collaborative future.

Today I joined a small group for a media tour of a brand new additive manufacturing facility built with that future in mind as Materials Solutions, a Siemens business, celebrated this week’s grand opening in Worcester, UK.

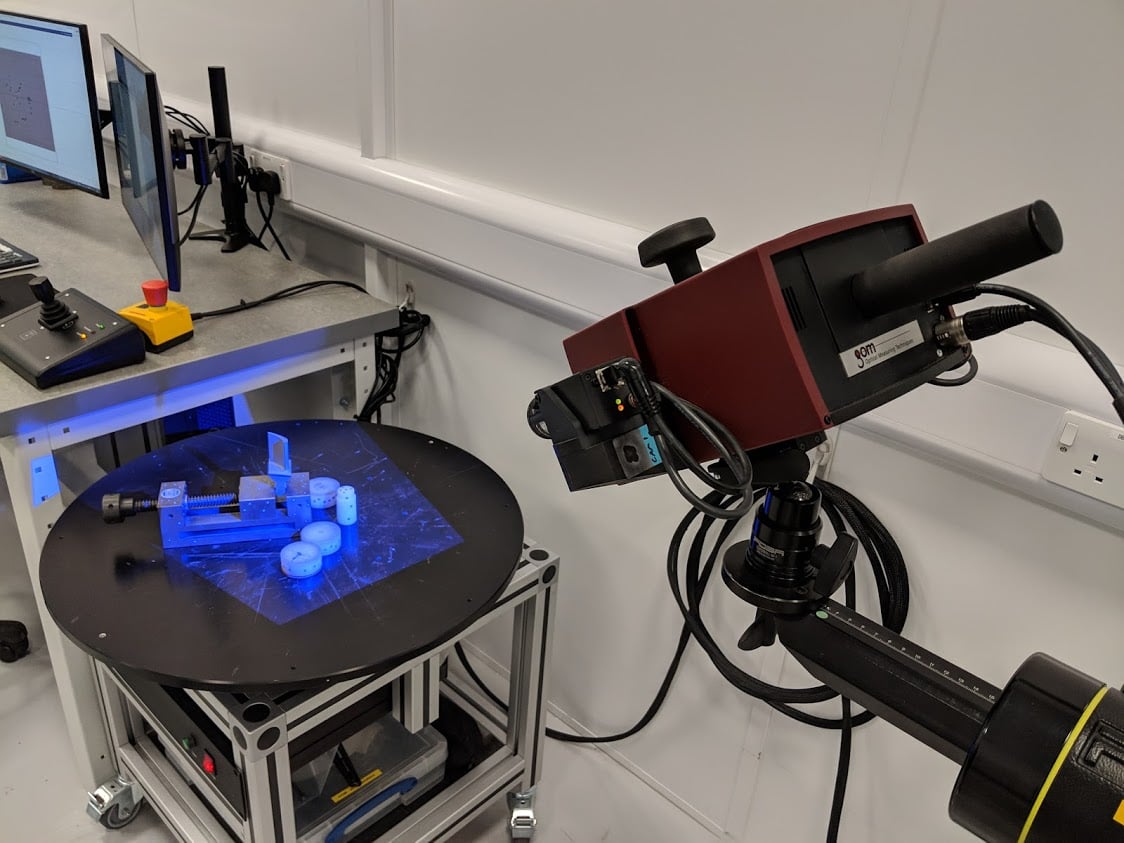

The 4,500-plus-square-meter facility is built to house about 50 3D printing systems, as well as dedicated floor space for quality control and inspection, post-processing, reverse engineering, and virtual reality to tie in necessary components of end-to-end additive manufacturing.

![Markus Seibold, Vice President Additive Manufacturing, Siemens Power & Gas, discussing additive manufacturing focus at Siemens [Image: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a0ad7c3cd.jpg)

“We do not do 3D printing; we do additive manufacturing,” Markus Seibold, Vice President Additive Manufacturing, Siemens Power & Gas, explained during a sit-down session. “Additive manufacturing is the 3D printing, the quality check, the post-processing, the supply chain, the powder management. It is the serial production, it is the full ecosystem.”

Messaging in today’s meetings, discussions, and tour came down largely to that theme of togetherness.

Just as additive manufacturing isn’t just one thing, neither is Siemens’ vision for the future of the technology. It’s collaborative. 3D printing needs design and post-processing for full functionality, while the team at Siemens is driving a vision focused on co-creation. Working with, not just for, customers creates partnerships and targeted solutions.

![Vladimir Navrotsky, CTO of Siemens’ Power Generation Service, examines benefits of additive manufacturing [Image: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/Siemens10_img_5eb0a0adeeb1f.jpg)

“Everything is new,” Vladimir Navrotsky, CTO of Siemens’ Power Generation Service, said. “We have the chance to integrate quality control into the process itself because it is a new process. With digitalization, we monitor the whole process, analyzing and building together. New technology enables us to create new designs which were not possible previously.”

![Phil Hatherley, General Manager, Materials Solutions - a Siemens business, sharing a look at the industrialization of additive manufacturing with the new facility [Image: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a0ae6f14a.jpg)

Phil Hatherley, General Manager, Materials Solutions, led a tour through the shop floor, as we got a good look at the working printer farm as well as inspection and post-processing areas.

Materials Solutions has “a strong history with EOS,” Hatherley noted as we walked among several running machines and the new M300-4 system. Machines in the facility are each dedicated to a specific material, avoiding the possible consequences of cross-contamination and ensuring smoother operations.

A highlight during the walkthrough was the reality; Hatherley shared ambitious visions for the future, but all were grounded in the realities of today’s manufacturing environment.

A complex part took 39 days to build, proving the design out and performing successfully in tests. Ultimately, another manufacturing technique proved a better option for the large part; imagine a customer approving the 39-day build part and ordering 20 in a month. In post-processing, Hatherley held up the “tool of choice in the real world” for support removal: a hammer. For all the finesse of designs achievable, sometimes a hammer and chisel are still the best and most reliable route to taking off support structures.

Real parts are being built in real conditions by real engineers. For a press tour especially, this was refreshing.

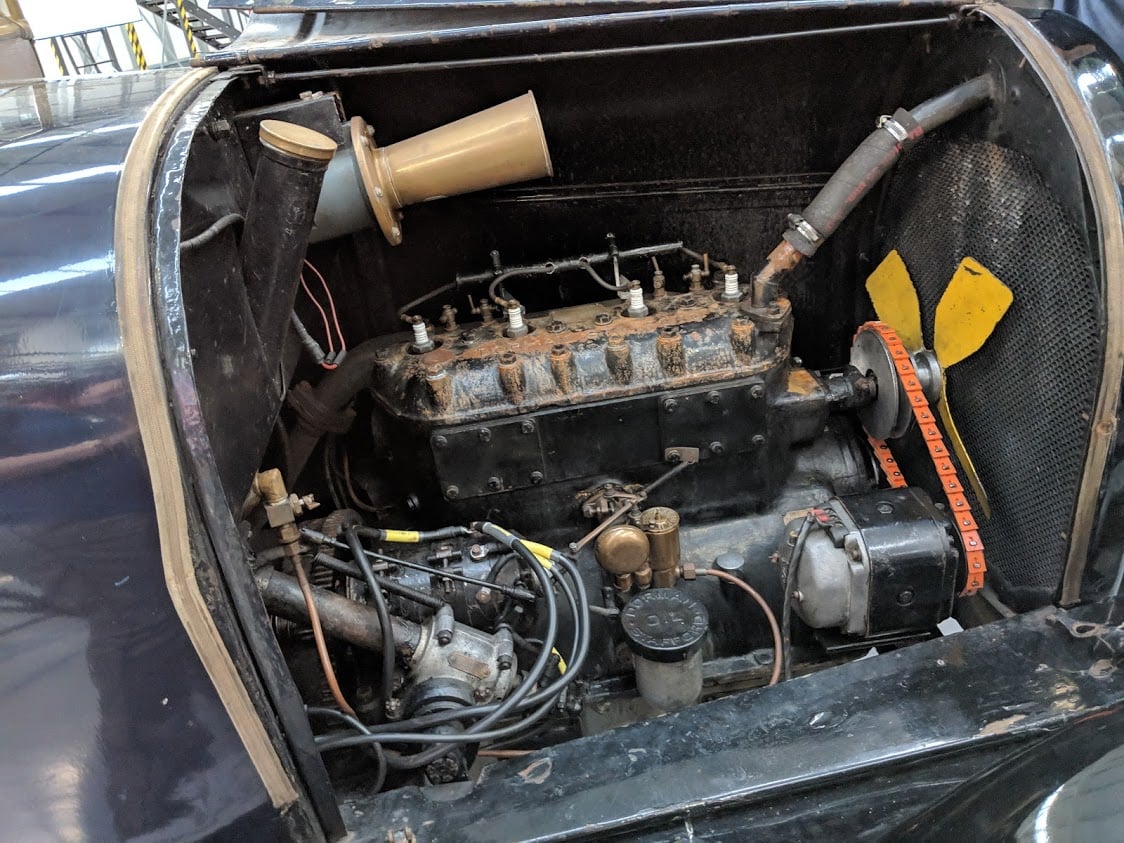

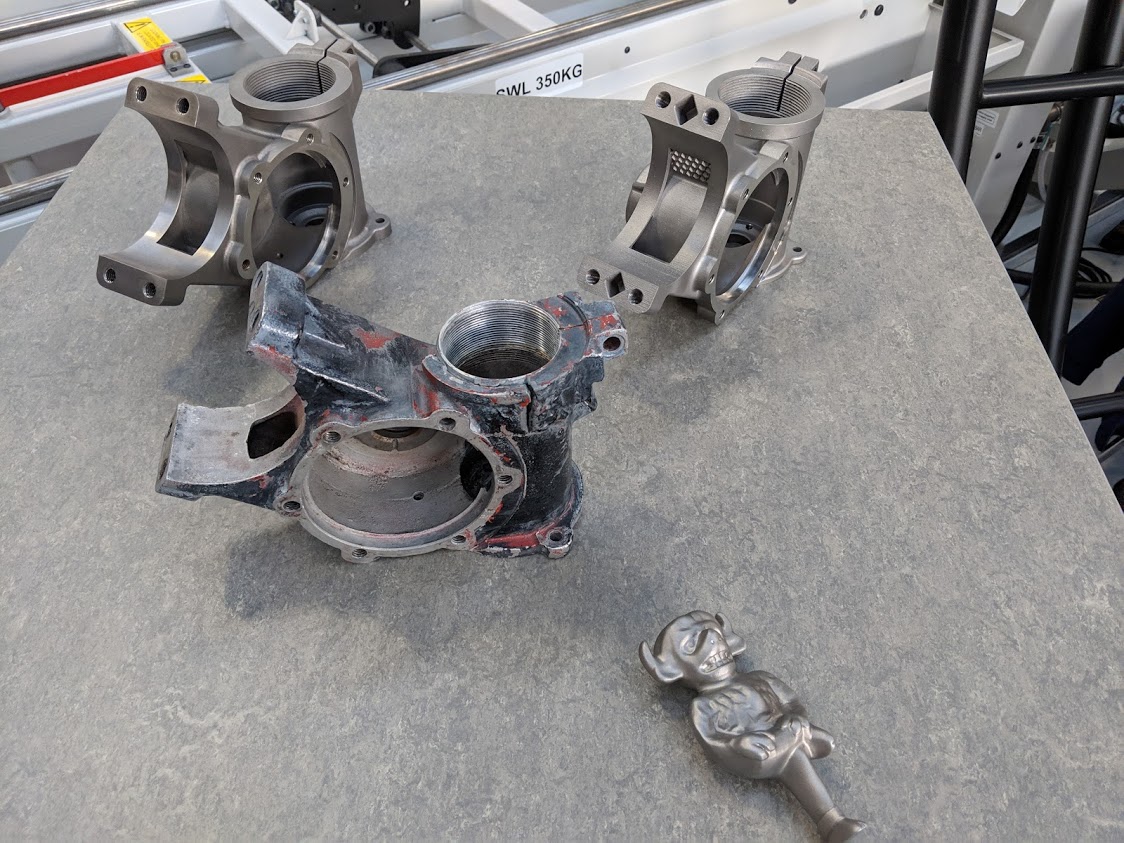

We closed out the walkthrough looking at a car built circa 1920. There are two of them, called Gin and Tonic, engineer Andy Jones explained: Gin is on the floor now as a display, while Tonic is having parts reverse engineered to build it back up. Reverse engineering is helping Tonic to take shape again, as an engine component and decorative imp are scanned, modeled, 3D printed, and finished for installation. The tangible display of automotive refitting served for a hands-on look at some of the specialty applications for additive manufacturing today.

We’ll have more details soon from the tour and chats, including a sit-down interview with Hatherley, Seibold, and Navrotsky.

![Phil, Vladimir, and Markus embody the spirit of togetherness driving additive manufacturing forward [Image: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/Siemens01_img_5eb0a0b57951f.jpg)

Via Materials Solutions and Siemens / All images: Fabbaloo

Volumetric 3D printing could be the biggest shake-up in 3D printing history. But who is working on the technology? We made a list.