Israel-based XJet has opened a $10 million Additive Manufacturing Center, billed as the world’s largest for 3D printing of metals and ceramics.

At the grand opening Monday morning in Rehovot, the new AM Center shined as only a new manufacturing facility can. The center, filled during the event with the hum of visitors and of a few running XJet Carmel systems, was well worth seeing. Scheduling the international trip saw my arrival timed part way through the morning’s presentations, which featured speakers from Oerlikon Group, Professor Oded Shoseyov, and Syqe Medical (the last of which I did arrive in time to hear), as well as from XJet itself. Informative and dynamic as these sessions were — and they undoubtedly were, offering glimpses into real-world applications and developments highlighting the impact of ceramic and metal additive manufacturing — it was the AM Center tour and following manufacturing facility tour that took most of the focus.

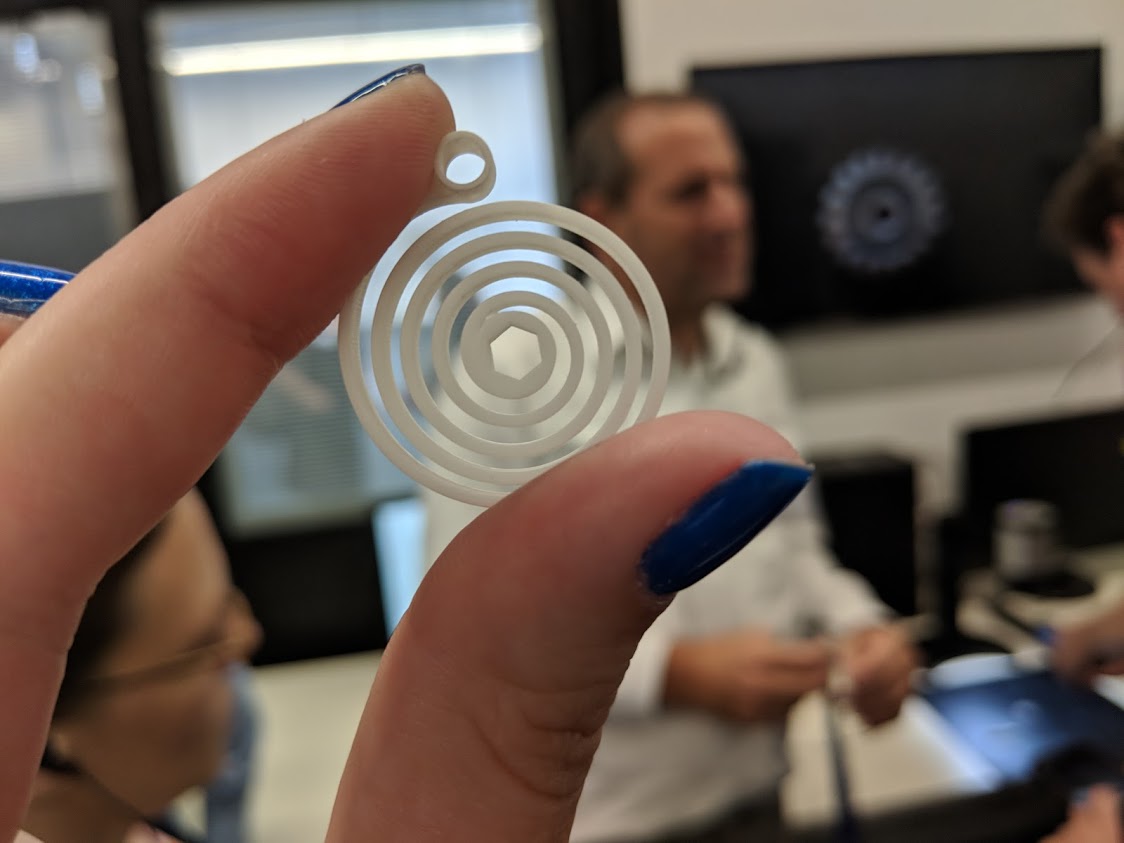

The 8,000-square-foot AM Center houses the capabilities for 3D printing with stainless steel or zirconia, and during the visit we saw the printing and support removal processes in action, as well as finished prints to examine the fine-detail qualities achievable with the company’s NanoParticle Jetting (NPJ) technology.

The XJet team is now more than 100 strong, a testament to the growth of their investment into company as well as technology. NPJ is unique when it comes to additive manufacturing technologies, as the Carmel series allows for inkjet printing with ceramics or metals on the same system. Each print job utilizes a ceramic or metal material as well as a support material that comes off relatively easily upon submersion; we saw a quick demonstration of a part dropped into a solution to disintegrate the supports in front of our eyes.

Company executives were on hand throughout the day to talk journalists, analysts, customers, and partners through their process; CBO Dror Danai led my group step-by-step through the center, while CEO Hanan Gothait shared his enthusiasm throughout the event and Dr. Ophira Melamed, who is leading the center’s operations, shared a look into operations and strategies during another conversation.

The company has been looking toward capabilities of printing with both ceramics and metals in the same build, as Gothait noted:

“XJet Carmel AM systems are currently available with one of two printing materials, stainless steel or zirconia. Our vision is a platform that prints with a multitude of metals and ceramics on the same part. We will use the AM Centre to develop and demonstrate specialized applications, print test parts for our global customer base, and trial new metal and ceramic materials.”

As both XJet and its partners noted in presentations and conversations, a key point of interest in the technology is NPJ’s ability to create super fine detail. A ceramic drill bit has been XJet’s showpiece of choice, seen recently at both RAPID + TCT and the new AM Center. It has, as the company describes, “more than 2,400 connected cooling channels that are ~190 microns in diameter.” NPJ can achieve “remarkably thin layers of just a few microns,” XJet says, “compared to dozens of microns in powder-based ceramic and metal AM technologies.” Taking capabilities to such fine control, and doing so repeatably and reliably, is an achievement indeed.

Confidence in such an achievement shines through in the new AM Center; a $10 million investment is no small feat for a young company. Danai underscored this point when we spoke (full interview coming soon), as NPJ is “a technology that is different.” The place of powder bed technologies is not to be diminished, as XJet is targeting its applications carefully. Finding a best-fit technology solution will be increasingly important for customers around the world as additive continues to move toward manufacturing, as adoption both broadens and deepens, and as more solutions are developed, proven, and commercialized.

The opportunity to join XJet in Rehovot Science Park for its grand opening was eye-opening. Speaking with company execs and getting hands-on with the parts allowed for a closer look at a very interesting and extremely promising technology; we’ll be sharing more from the visit soon.

[All images: Fabbaloo]

Women in 3D Printing is pleased to introduce its first annual conference.