Desktop Metal is previewing new Fab Flow software and it looks incredibly promising.

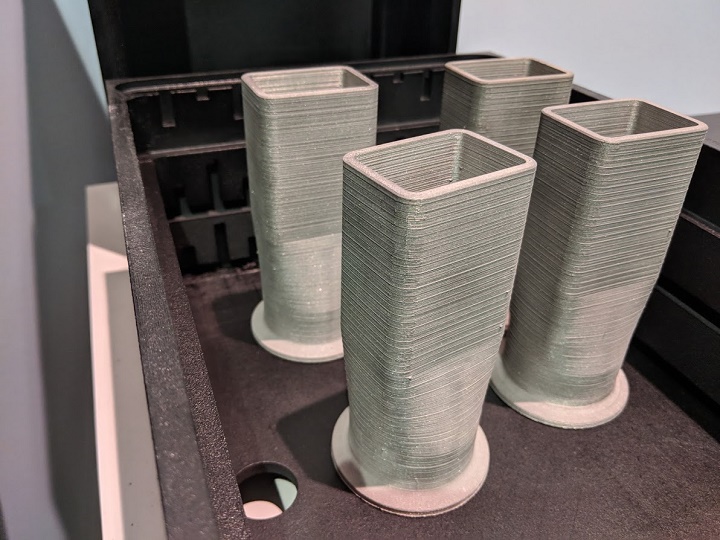

As I was speaking to Desktop Metal CEO Ric Fulop at IMTS this week during our customary conference catch-up, he pointed to some of their biggest draws at the show. First we looked to the Production System, the company’s large-scale offering that’s “really like a printing press,” which they were showing off for the first time in Chicago.

“Everyone’s asking how it compares with HP,” he said, referencing the unveiled-at-IMTS Metal Jet technology. “You’d need seven of those to reach the throughput of one of these. Ours has separable supports, you can make movable parts; it has semi-automated depowdering. It’s inerted so you can work with reactive materials.”

Two betas are set for installation before the end of this year, with early 2019 anticipated for the first customer delivery, with 2020 broad Production System availability.

We looked next to the company’s recent announcements. IMTS heralded three introductions from Desktop Metal, and they shared two ahead of time as we looked into the Studio System+ and Studio Fleet launches last week.

The third introduction is a preview, as Desktop Metal unveiled Fab Flow software.

For a demo of the new offering and a look into the whats and whys behind its creation, I caught up with Desktop Metal Co-Founder and Vice President of Software Development Rick Chin.

“We wanted to expand and accelerate software,” he told me of the intent. “When designing this, we truly focused on two key aspects: clarity and control.”

Fab Flow, targeting use in internal model shops, is cloud-based, hardware-agnostic, and white labelled, offering a significant amount of freedom in its deployment.

Its main application is for ordering parts, with features designed to “head off problems at the pass” prior to the start of a print job. The software was designed based on feedback, as internal shop managers had shared their needs for more accessibility and efficiency in tracking projects. Shop managers can input a broad variety of information into Fab Flow, including all of their in-house equipment and capabilities.

Chin walked me through the easy-to-follow steps in simultaneously planning jobs for a Studio System and a Stratasys Fortus machine, as parameters and specs for more than 200 3D printers and their compatible materials are available from easily navigable pulldown menus.

“We’ve already loaded profiles for major — and some non-major — manufacturers for machines and materials offered,” Chin said.

From the time it is uploaded, each design undergoes real-time geometric analysis as the system clearly flags any potential issues for a given print job. The design verification process ensures printability and optimal settings for given materials and systems. Once finalized, an auto-generated quote details next steps.

The shop user can see the exact workflow of each job in process, including a handy flowchart that allows for a consolidated look at all active jobs and equipment. Model shops thus have immediately at hand a look at where any potential bottlenecks may arise on busy production days, as well as gain an understanding of which machines aren’t used as frequently. Live job tracking ensures traceability through the production process.

“We’re trying to make this really easy to deploy; it can be set up within 30 minutes. It’s really cool that a shop could provide this to their users. Because it’s white labelled, users can apply their own branding so their customers are looking at their site, not ours,” Chin continued.

I’m not a software person, something I freely admit. That said, I would be completely comfortable navigating Fab Flow; its user-friendliness is next level.

When a few small errors were identified and auto-corrected in the example job, a new file version appeared that showed amendments understandable at a glance: material removed was red, added material was green. Chin smiled as he described this, adding simply that that was one of their goals with Fab Flow: “Clarity.”

What I saw at IMTS was an early preview; the beta is coming. Internal shop managers can request access to the beta here, as the team looks to gather community input for feature development prior to broader release, which will hopefully be before the end of this year.

While the Studio Systems have been hitting the market and the Production Systems are getting closer, it can be easy for the fancy machines with their accessible entry into metal 3D printing to take all the attention. One thing Desktop Metal has been making very, very clear this year with the February introduction of Live Parts and this preview of Fab Flow: perhaps the most compelling stories are on the software side.

Via Desktop Metal

[All photos: Fabbaloo]

MiniFactory’s new software produces a very useful report for each 3D print that may be important for clients. We had a close look at one.