![The mostly 3D printed Marble Clock [Source: Instructables]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a8422f997.jpg)

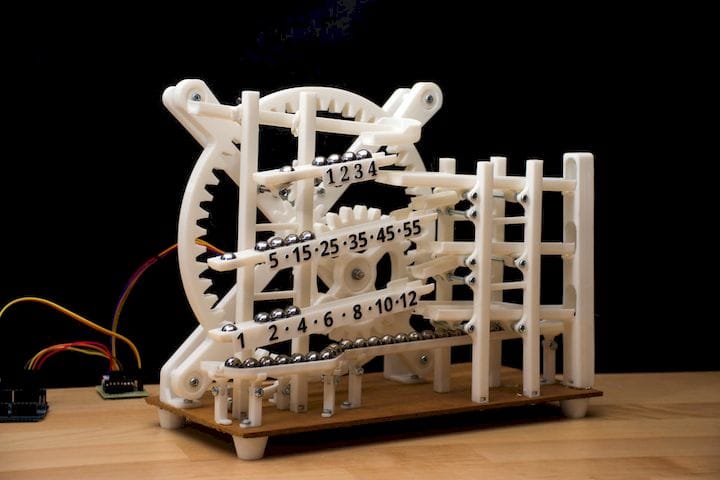

This week’s selection is the smooth Marble Clock by Görkem Bozkurt.

Bozkurt, a physics major at Bilkent University in Ankara, Turkey, designed a fascinating mechanical clock where most of the parts are 3D printed. And it actually works!

The system, powered by an electric motor, turns a series of gears and tilting rails to shuttle ball bearings around in a manner that tells the time. Time is read out by matching the most recently deposited ball bearings on each of the three tracks.

The mechanism is ingenious; the main gear turns once per minute, depositing a ball bearing on the “one minute ball bearing” rail. When that’s full, it spills over into the “five minute bearing” rail, and finally to the “one hour” rail.

You can see how this works in the video. Watch until the end:

It could be argued that this is actually a digital device, even though it may initially appear to be an analog clock of some type. The ball bearings represent discrete quantums of time and thus you can only read out “whole” time numbers.

Why did Bozkurt design and build this? He explains:

“I’ve been a long time fan of ball clocks. I’ve seen one when I was a kid in a novelty store. And I just stood there watching it endlessly. The movement of the balls with time was magic to me. After I heard about the clock contest on Instructables. It gave me the Idea to try to design and build a ball clock from scratch. So I started to sketch on paper.

What I wanted to do was to design a different lifting mechanism instead of the traditional rotating scoop type design. So then it hit me. I was going to use a rotary to linear motion mechanism so while the mechanism was rotated by a motor the ball would be moving in a line, up and down. Creating a little illusion.

The rails were mostly inspired from other ball clocks but I had an idea to create a bell mechanism so everytime one hour passes there would be a sound. Unfortunately, I could not build this into the project.”

Bozkurt’s design requires a 3D printer with a 250 x 250 x 150mm build volume, so this may not be possible on all devices.

![Parts required to build the 3D printed Marble Clock [Source: Instructables]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a8428a3b8.jpg)

There are a number of non-3D printed parts required for this, including 38 nuts and bolts, a microcomputer of some type to run the motor and of course ball bearings.

How many do you need? Bozkurt explains:

“100 x 11mm Steel Ball (you only need 30 but they get lost quite easy)”

Right.

Via Instructables and Görkem Bozkurt

This week’s selection is a 3D printed Coronavirus!