![A complex aerospace generator housing using lattices made by Betatype for Safran Electrical & Power [Source: Betatype]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a6127b939.jpg)

More and more we’re seeing use of lattice structures in component design.

A lattice is a complex foam-like structure that is increasingly used in 3D printable designs for industrial components. The idea is that a lattice provides support to a specific geometry but without using the same amount of material.

So why not simply use foams, which are often less expensive to produce than 3D printing? It’s because the foam structure itself is random and it often cannot provide nearly as much strength as a coordinated lattice structure.

But for eons such structures were simply impossible to produce. Traditional manually operated making tools would require extreme durations to carve out the lattice. Besides, no one knew how to form an appropriate structure to match the functional requirements. Even when automated CNC machines appeared in the 20th century, lattices were typically not used due to their geometry often preventing CNC access to deeper parts of the structure.

Thus no lattices. In fact, lattices were for a long time not even considered as a design element.

But that’s changing, and changing rapidly.

The advent of 3D printing technology has changed all that due to the nature of the additive process: objects are created layer by layer, meaning the equipment has indeed access to the inner portions of the geometry, thus getting around the earlier CNC problem.

This technology, combined with the ability of powerful software to generate lattice 3D models that do match the functional requirements, optimizing for specific use scenarios and using a minimum of material creates many new opportunities. The idea of creating components that are of lower weight, potentially cheaper to produce and of the same or better functionality can be quite attractive.

![A complex aerospace generator housing using lattices made by Betatype for Safran Electrical & Power [Source: Betatype]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a612df751.jpg)

One barrier remaining to mass adoption of this approach is cost: the cost of 3D printed objects, particularly in metal, is still prohibitive for many industries. But for any industry already accustomed to high component prices, this is not a barrier. The only remaining barrier is understanding, training and acceptance of the unusual results.

This seems to have been overcome in the aerospace industry, where, as you could imagine, lightweight parts are extremely valuable. Even a slight reduction in weight has a dramatic effect: airlines run their operations on a very thin margin, so a one percent advantage in operational cost is significant.

It now seems that a good portion of the aerospace industry has caught on to this approach and it is now becoming commonplace.

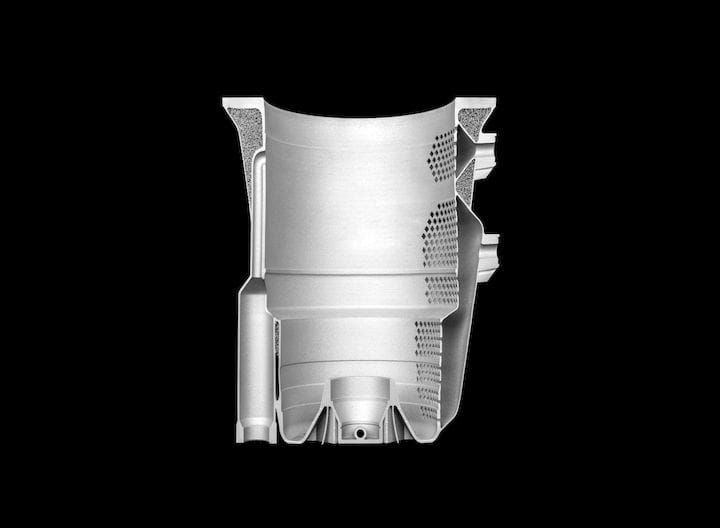

One interesting application I saw recently was the use of complex lattices in an electrical generator housing. Safran Electrical & Power, a manufacturer of electrical systems for aerospace, has been asked directly by their clients to produce lower-weight components through the use of additive manufacturing. This is a strong statement, where customers are literally demanding use of an advanced technology.

To that end Safran Electrical & Power enlisted UK-based Betatype, a metal 3D printing specialist, to assist in the development of a lattice-based housing. They successfully completed the project as seen in the images in this post.

![A complex aerospace generator housing using lattices made by Betatype for Safran Electrical & Power [Source: Betatype]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a61333291.jpg)

Note the the extremely complex and fine lattice employed in this design: it provides the necessary strength, but also eliminates a substantial amount of material. Imagine if this object were solid, as it likely was in past designs. The amount of material removed is substantial, making the weight of the part proportionally lighter.

Now imagine if EVERY part on an aircraft were made in a similar manner: you’d lose an enormous amount of weight that could be used to reduce fuel costs, add passengers or enhance services.

That’s why aerospace is so interested in 3D printing.

Via Betatype

Eric Haddad is the founder and Pilot in Command of 3DAeroventures, a Texas-based outfit specializing in 3D printed RC aircraft.