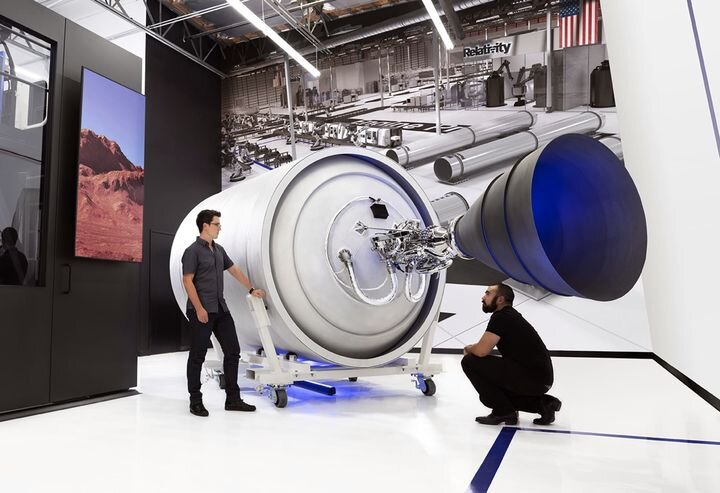

![Relativity Space’s 3D printed rocket [Source: TechCrunch]](https://fabbaloo.com/wp-content/uploads/2020/05/relativity-space-stargate_img_5eb08b87292ab.jpg)

I’m reading a story on TechCrunch in which they interview the folks from Relativity Space, and had a thought about industry disruption.

Relativity Space’s 3D Printing

The story correctly proposes that the California rocket company startup could shake things up in that industry, saying:

“Fresh off a $140 million funding round in October 2019, Relativity’s model could provide another seismic shift in the economics of doing business in space, and has the potential to be as disruptive to the landscape — if not more so — as SpaceX.”

This is because Relativity Space has chosen an interesting strategy that no other company in that domain has attempted: 3D printing an entire rocket. But it’s not just that — the company is using very sophisticated design approaches to create components that fully leverage all the capabilities of their enormous “Stargate” robotic metal 3D printer. The eventual product they produce may function like a rocket, but its internals will be different due to this unusual approach.

Disruption By 3D Printing

That’s all fine, but I wondered whether this type of disruption would occur in other industries by other aggressive startups that attempt to leverage 3D printing tech.

After some thought, I think the answer could unfortunately be “No”, or perhaps “Not very many”.

Why do I think this? It’s a simple matter of financial arithmetic.

Rockets are traditionally a very expensive matter. The rockets that exist were few in number, meaning the entire burden of their development — materials, salaries, properties and other resources – must be recouped in only a few sales of the rocket.

Even worse, due to the critical nature of a rocket flight, the parts must be near-guaranteed of flawlessness, and this requires considerable testing, certifications and development time. This makes the rocket flights quite expensive.

Expensive Components Allows 3D Printing

In economic theory, when something is priced high this presents an opportunity for an innovative competitor to develop an alternative solution that is priced lower. Sometimes this is done by volume, as there is an economy of scale effect in many cases. But for products with lower unit sales, that’s not an option.

Instead it takes an innovative approach, often using a new technology not leveraged by the existing product makers to open the door. This is what has happened in the aerospace industry, and in particular for Relativity Space. They should be able to produce a rocket at a lower cost.

Typically the first instances of a new approach are the most costly, as the optimizations possible have not yet been discovered through the experience of product use. But over time opportunities for improvement are identified and incorporated into future designs. This means that the most expensive unit is often the first one introduced.

But the higher expense of the first instance of an innovative product is ok, because the traditional competitor’s pricing is already higher. The traditional high pricing of components creates an economic window through which the initial attempts at innovation can fly through.

In industries where products are typically expensive this phenomenon exists. We’ve seen it many times in the aerospace world, and it also exists in the healthcare industry. In healthcare products are very often customized to the patient, meaning the production is expensive. Again, that opens the door for an innovative 3D printed solution.

Similar things are starting to happen in the automotive and oil & gas industries. This is in fact what we’re seeing today in 3D printing; those industries are all lighting up to the technology.

Other Industries Using 3D Printing

But what happens after that? What other large and widespread industries have very expensive components? I can think of only a few:

-

Military

-

Certain types of construction

-

Certain types of mining

Most other industries are worlds where parts are relatively inexpensive. That is to say, their 3D printed equivalents are more expensive, and often much more expensive. In these situations, there are only limited windows of opportunity to fly through.

In order to break through to a wider array of industries, 3D printing will have to undergo some form of dramatic change. That change must involve lowering costs of production.

I am aware there are some folks working on this very problem, directly or indirectly. Some day in the not-too-distant future we may see these 3D printing technologies arrive on the commercial scene and then things will begin to change. And quickly.

Via TechCrunch