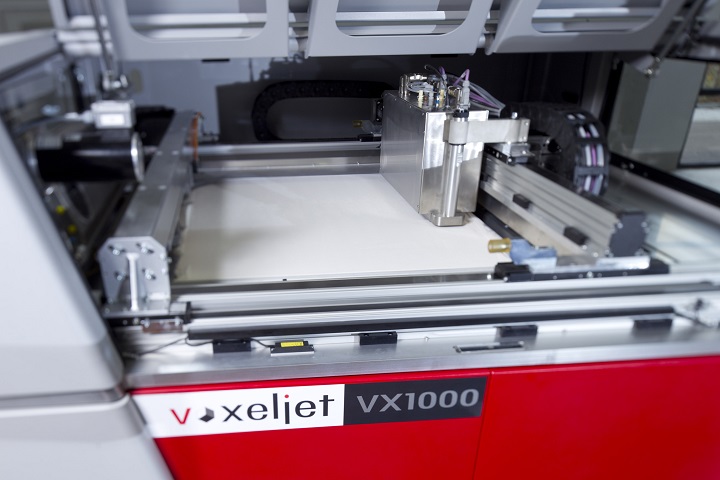

![voxeljet's VX1000 system [Image: voxeljet]](https://fabbaloo.com/wp-content/uploads/2020/05/vx1000_img_5eb0a92650d7e.jpg)

Production is in sight for additive manufacturing, and voxeljet is looking to lead the way, the company tells us.

This morning, James Reeves, Managing Director at voxeljet UK, reached out with an interesting look ahead in the latest positioning to “reinvent the manufacturing landscape.” He published a teaser today hinting at an interesting work in progress: “the world’s first fully automated 3D production solution capable of replacing conventional manufacturing in serial-production.”

The additive manufacturing industry is as a whole looking toward addressing production-level solutions, so let’s not focus too much on that “world’s first” aspect — and look instead to the viability of voxeljet’s proposal.

The company is collaborating with partners toward this “major step,” coming up with an “integrated solution [that] allows for the automated production of components used in the casting process of critical engine components.”

Key to real-world application in production are several factors, often boiled down to considerations of speed, cost, and quality. The voxeljet tease points to significant focus on the first of these aspects, as Reeves’ report notes that the “VJET X-IOB is ten times faster than our currently available 3D printers (reaching a print speed of 400 litres per hour” and utilizes automated pre- and post-print processes, reducing hands-on intervention. The speed goes hand-in-hand with a reduction in costs, with Reeves noting:

“When applied to engine manufacture these benefits include improved engine performance and fuel efficiency, reduced costs per part and an increase in flexibility in production to allow for multiple variants on the same line.”

Reeves was kind enough to provide a bit of a look behind the curtain, though we’re still an undisclosed length of time away from a larger reveal. Many details are at this time confidential, including system specs and the first customer putting it to use.

![Prototyping a car design [Image: voxeljet]](https://fabbaloo.com/wp-content/uploads/2020/05/prototyp_autodesign_teaser_img_5eb0a926b4d49.jpg)

What Reeves could reveal at the moment is that this project “is the result of a strategic R&D focus for voxeljet: to achieve a full production scale system for AM parts.”

Looking at the background of this project can give us a good idea of where we can expect the new solution to appear in the likely-not-too-distant future.

Reeves tells me:

“Globally, over the last few years, we have been receiving increasing and serious enquiries for serial production from a few 1000 up to 250,000 parts per year. Although our platform technology has always been fast we knew that to hit >100k parts we needed to be much, much quicker. So we set ourselves really ambitious targets that have required some innovation approaches. We don’t believe that production can be achieved by simply putting multiple machines together – the productivity of the machines itself needs improvement.

“So we took a fundamental look at all parts of our process to identify the best areas for re-development. This has led to some great new innovations and a 10x increase in the throughput of the machines. We have coupled this with automated post processing (unpack, depowder, inspect, etc) which has been developed with partners. There is no manual intervention from printer to end part which takes out significant bottlenecks and costs.”

Details are a bit sparse at the moment, and Reeves notes that unfortunately more precise information is currently unavailable — but it sounds like this advance has great promise behind it.

Revealing the plans now is also a smart move on the company’s part as it deals with backlash following its recent Q2 results reporting.

We can expect to hear more soon from voxeljet as the busy company continues toward its ambitious goals.

“We are looking forward to the next phase of Additive Manufacturing and being at the forefront of it,” Reeves told me in closing.

A blog post reveals much of what happens behind the scenes at 3D print service Shapeways.