Charles Goulding and John Chin of R&D Tax Savers discuss 3D printing for motorcycles and motorcycle components.

Modern motorcycles have deep roots in American history from as far back as World War I. After World War I, Harley-Davidson became the world’s largest motorcycle manufacturer but by the 1930s, Harley-Davidson and Indian were the only two American manufacturers producing commercial motorcycles. On Friday June 29, 2018, in the midst of Harley’s tariff and trade war strategy planning, USA Today had an article about how Harley decides where to source their components from by factoring in quality, availability, reliability and cost. Harley-Davidson motorcycles are assembled in the US, but their parts are sourced from a variety of countries. The table below presents the Harley country of origin for some major components provided by USA Today, along with some of the 3D printed opportunities described by our firm.

Harley-Davidson R&D Tax Saver Reference

Italy

Brake clutch parts from Brembo See Brembo section below

Japan, Mexico and China

Electrical components and wiring harnesses See our Electronics article

Japan

Showa-brand suspension components See our Bike Article

Trade wars and tariff levies force the industry to revisit their global supply chains. With today’s 3D printer innovations, this can result in 3D printers being implemented into new production and parts facilities. Motorcycle companies similar to Harley-Davidson, such as BMW and Polaris that participate in the improvement of products and the development of new ones, are eligible to obtain U.S. R&D Tax Credits.

The Research & Development Tax Credit

Enacted in 1981, the federal Research and Development (R&D) Tax Credit allows a credit of up to 13 percent of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

-

New or improved products, processes, or software

-

Technological in nature

-

Elimination of uncertainty

-

Process of experimentation

Eligible costs include employee wages, cost of supplies, cost of testing, contract research expenses, and costs associated with developing a patent. On December 18, 2015, President Obama signed the bill making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit can be used to offset Alternative Minimum Tax and startup businesses can utilize the credit against $250,000 per year in payroll taxes.

Brakes

The first category of Harley-Davidson supply components listed are Brembo brakes from Italy. 3D printed brakes have been implemented into various hyper cars such as the Bugatti Chiron, but the technology for 3D printing brakes is not yet available for regular production vehicles. We anticipate that eventually production level 3D printer applications will be developed for all vehicle categories.

BMW

BMW is no stranger to 3D printing; their i8 Roadster utilizes 3D printing to create the mounting for the top cover, an impossible task for traditional casting methods. In the past, BMW restored Elvis’s BMW 507; additive manufacturing played a big role in restoring the door components. BMW has an additive manufacturing center in Munich that produces around 140,000 3D printed parts per year, as described by BMW below:

“The Additive Manufacturing Centre in Munich:

Here’s where it all comes together. Well over 100,000 precision components are developed and manufactured here every year – ranging from prototypes to discontinued parts for classic cars, as well as small plastic mountings and highly-complex chassis parts made of metal.”

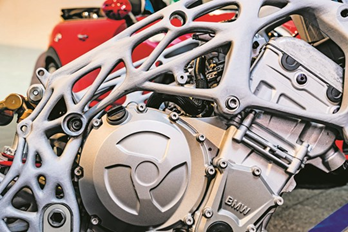

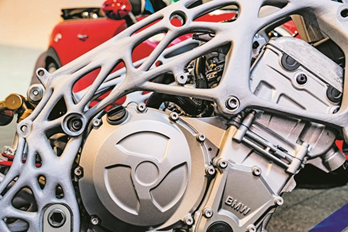

BMW sees a future where customers are able to customize various parts of their vehicle with the capabilities of additive manufacturing. On BMW’s Digital Day event, a mysterious motorcycle chassis was put on display, upon further investigation, it seemed to be completely 3D printed. BMW’s Motorrad is always looking for innovation and it seems that they are looking at replacements for the traditional metal chassis they usually use. Although this new bike frame piques interest, BMW has disclosed very little information on this prototype. BMW sees various benefits from 3D printing, but the main concepts are that it is faster and less expensive than traditional methods.

Polaris

To compete with Harley-Davidson, Polaris bought the Indian Motorcycle brand in 2011. Polaris then took the competition to the next level by using a 3D printer. In just three months, Polaris was able to design and produce a prototype ready for the showroom, a process that would have taken 15 months with older technology. Polaris CEO Scott Wine said, “This development is more than 3D printing technology and the new sleek design of the Indian, it’s about the competitive advantage enabled by 3D Printing.” In just over two years after the purchase of Indian, Polaris was able to bring three motorcycles – Indian Chief Classic, the Indian Chief Vintage, and the Chieftain – to the market. Polaris has several Stratasys 3D printers on location; this helps speed up the prototyping process and ultimately reduces the amount of time it takes to make a bike.

Ducati

Ducati’s wish is to reduce the time-to-market by reducing the design and prototyping process. They successfully achieved this by using FDM (Fused Deposition Modeling) prototyping systems from a Stratasys Fortus printer. FDM printing enables Ducati to build both concept and functional prototypes from polycarbonate and polyphenylsulfone. Compared to previous methods used, Ducati cut 20 months from the development process for the engine of their Desmosedici race bike. The Desmosedici race bike was designed and assembled in only 8 months, while the previous engine they built had taken 28 months to design and build. Originally, the engine was designed to utilize an oval piston configuration, but later on, engineers chose to redesign the engine with four round pistons that reproduces the working cycle of a twin cylinder engine. Additive manufacturing technology provided Ducati with the tools to recognize flaws and fix them in record time. Prior to acquiring the Stratasys sytems, Ducati was spending approximately 1,000,000 euros on prototyping. That cost was significantly higher than the cost of purchase, maintenance, and materials for the two Stratasys machines. Ducati has successfully and efficiently integrated additive manufacturing into their production process and R&D CAD Manager for Ducati Motor Holding Spa, Piero Giusti, says Stratasys’ printers are an integral part to their business.

TransFIORmers

TransFIORmers are experts in metal additive manufacturing. They collaborated with Renishaw engineers to optimize the upper wishbone component of a Moto2 motorbike. The wishbone component of a motorcycle has to be very sturdy and capable of withstanding a significant amount of force from steering. TransFIORmers original wishbone component was comprised of several smaller components wielded together while the new wishbone is made into a single piece of titanium. The company used a Renishaw AM250 additive manufacturing system to create the new metal wishbone. Topological optimization was used in the manufacturing process to create a part with similar characteristics to a normal part, but used less amount of material. The new wishbone component is lighter than the original component by a total of 40%. To make the motorcycle even lighter, TransFIORmers could consider using 3D printed wheels as substitute for regular ones. Metal 3D printing provides TransFIORmers with a simpler way to fine-tune adjustments to match chassis and kinematic requirements.

Conclusion

Various performance motorcycle companies are implementing 3D printing into their business model due to the capabilities of this technology. Metal 3D printing is a breakthrough technology, especially in the vehicle industry because it provides companies with a way to create a lighter part with the same or improved structural integrity. Competition is good for the industry; Polaris utilized 3D printing to leapfrog Harley-Davidson. In the July 25th issue of the Financial Times there is a major article entitled, “Harley Warns of Bigger Tariff Blow” describes how the tariff wars are materially impacting Harley’s bottom line. Strategic use of 3D printing technology can help offset some of this margin erosion. In July of 2018, Harley announced a new line of lighter motorcycles and an even smaller bike for emerging markets. These new smaller profile bikes require new lighter components which is a perfect opportunity for 3D printing its ability to reduce component weight.

Charles Goulding and Preeti Sulibhavi consider how two prominent automotive firms, Ferrari and Ford, are using 3D printing.