This could be a very big deal: Autodesk has taken up the challenge of opening up 3D printing to a much wider audience with Project Escher.

Project Escher is an exploration of removing barriers to 3D printing in order to increase usage and enable new forms of manufacturing.

Currently, 3D printing is often seen as a kind of standalone process: you design a 3D model and print it, done! But while that process actually works reasonably well these days, it drastically limits the opportunity to produce goods. The reason: because many useful objects are made from multiple materials, with multiple making processes and require multiple finishing processes.

Today’s standalone 3D printers just don’t have those capabilities, or if they do, they are extremely limited. Consider the two-nozzle extruder found on many 3D printers: is that truly multiple materials? What if you need a material that isn’t extrudable? The choice of materials today is wider than it’s ever been, but it’s still drastically short of what it should be.

Enter Project Escher from Autodesk. Here researchers are investigating ways to integrate multiple processes into the making process, generally focused around 3D printing. In this video you’ll get a good idea of their ideas:

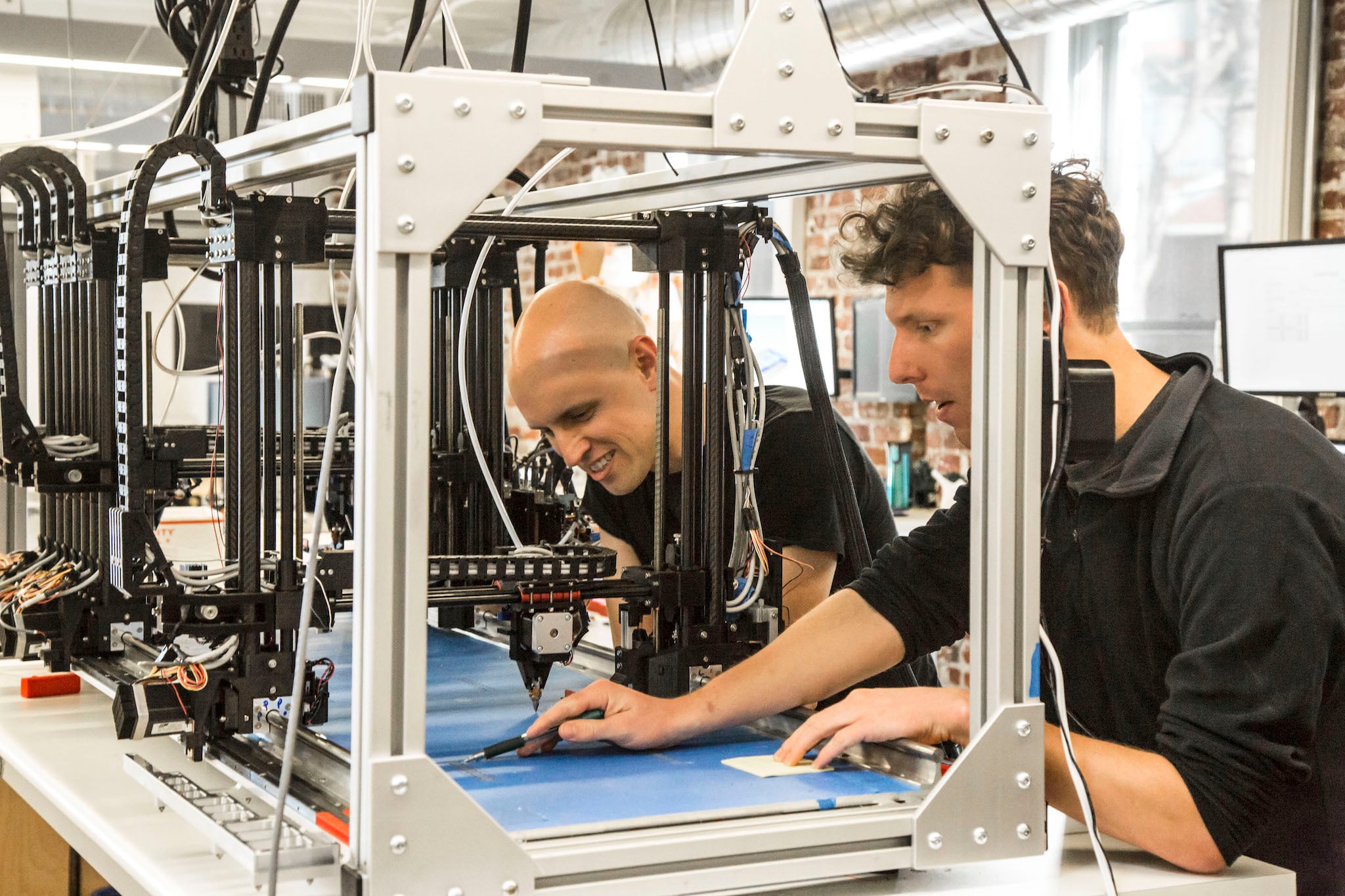

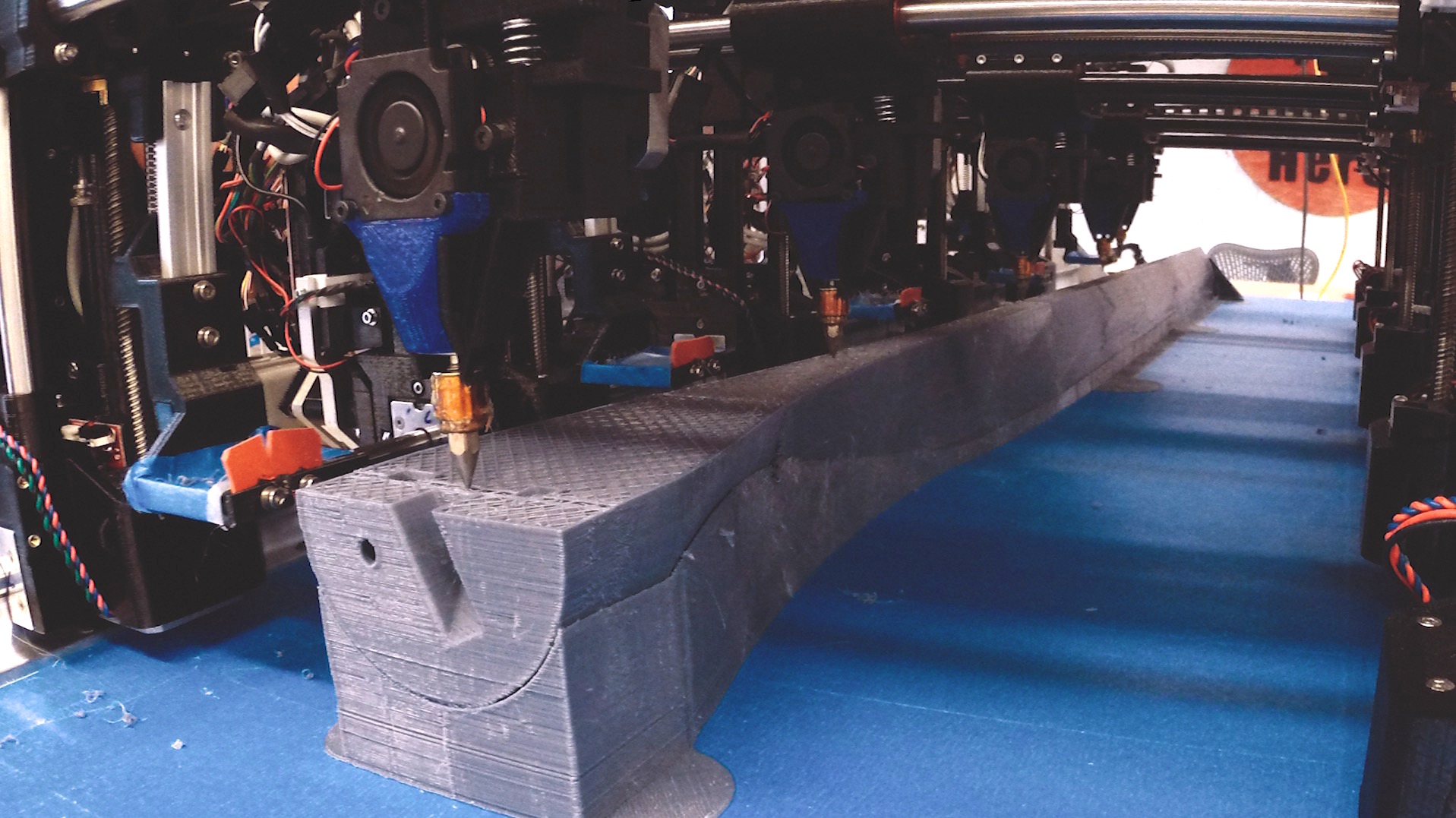

Their research (and practically everyone’s experience) indicates that manufacturing requires multiple steps as described above, and to increase the use of 3D technology, changes must be made to the making process. They have, for example, created multiple independent robots with interchangeable tool heads.

They wish to make the tool head changes automatic – as is currently done on many CNC machines, but strangely not on 3D printing equipment so much. They’re also talking about Pick-And-Place tools that would, during mid-print, insert pre-made components into the object in ways that would otherwise require multiple parts and post-print assembly.

In the video they also mention the idea of integrated metal casting, which I feel is ambitious, but if achieved would make such a machine far more powerful, since metal parts are more durable and useful in more applications.

I don’t know Autodesk’s timetable on this research, but it seems that their group will explore the technology in a number of ways, eventually identifying implementable aspects. If successful, I hope they’ll publish the results in the form of a reference machine, such as they’ve done with their resin 3D printer, the Ember. More than likely such a reference machine would take part in their Spark 3D printing platform, as well. From such reference designs we could see a small explosion of products and consequently changes in manufacturing.

Via Autodesk