Amos Dudley has somehow managed to design and 3D print a custom dental appliance for correcting his teeth, but is this really a good idea?

Dudley is an undergrad in a Digital Design program at the New Jersey Institute of Technology, and has accumulated skills in a number of 3D environments. Even better, his academic situation permits access to a number of commercial making machines.

Dudley’s teeth required minor correction, which would normally be accomplished with braces or a professional dental appliance through a licensed dentist, but having little money – but access to equipment and skills – Dudley decided to do it himself.

Incredibly, the student was able to successfully create a usable dental appliance for his specific situation. I won’t go into much detail on the steps he took, which he’s documented in brutal detail on his blog (link below), but here’s the gist of it:

- Capture an analog mold of the teeth using alginate powder in an easily-created impression tray

- Produce a solid positive cast of the teeth by dropping the mold in a tub of liquid permastone

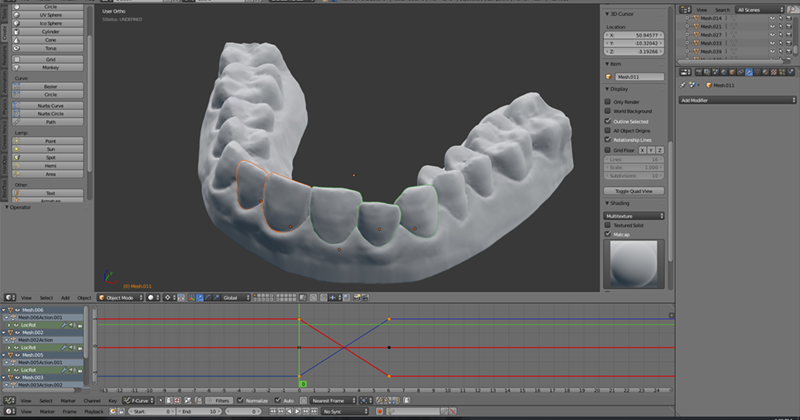

- 3D scan the solid cast with a high degree of accuracy (Dudley used a professional handheld laser scanner)

- Adjust the 3D model by isolating the offending teeth and “tipping” them correctly in the model

- 3D print the adjusted teeth model in reasonable resolution (Dudley used 0.1mm layers)

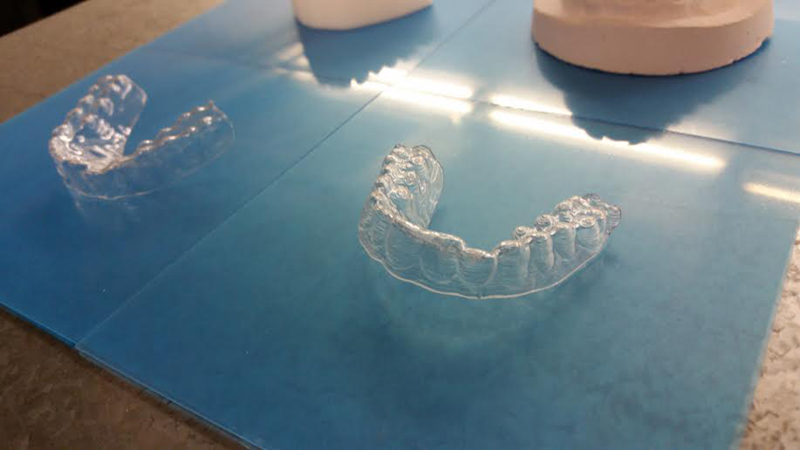

- Use the 3D print as a mold for vacuum forming clear plastic in the shape of the adjusted teeth. Dudley used a non-hazardous co-polyester material with suitable safety certifications

- Trim the formed clear plastic to fit comfortably in the mouth

It’s a long process that can only be reasonably be done by someone with excellent CAD skills and access to several pieces of pricey equipment. That and some courage.

Dudley’s approach worked for him, as shown here in the before and after images of the teeth.

However, there are so many considerations here it is unlikely this could ever become a widespread technique.

The problem in this process isn’t that it’s a bunch of complicated steps. Instead, it’s that there are so many things that could go wrong along the way. It’s the “wrong” stuff that is hard, not the easy path if everything works.

One major consideration here is that tooth management is complex and requires skills to perform. That’s why you go to a dentist; it’s not so much because they can give you a filling or whatever, it’s because they can assess a situation and determine the best course of action. That takes considerable training and experience, which is not available to the casual dental appliance maker. What if Dudley’s teeth were not in an easily resolved configuration? How would you know an easily resolved situation from a difficult one? Would you guess? I’d prefer a dentist make that assessment.

Materials are also complex in situations involving human contact. Dudley correctly selected a plastic that is likely safe, but would other casual dental appliance makers do so? Would people use incorrect plastics that are not safe for human contact? Would you want a piece of plastic containing, say, toxic lead in your mouth for six months? Are you absolutely certain the plastic you select is safe? Do you trust the (in this case) eBay supplier to ensure the plastic is actually what it is supposed to be?

These and similar questions can be asked, but here’s the thing: the dental industry HAS answers to all of them. That industry, like many others, has over time developed rigorous processes and supply chains that ensure proper results – and if they don’t, there is also provision for blame: a supplier didn’t meet the specifications, etc.

In the case of Dudley’s experiment, there is no insurance and only the DIY maker to blame if something goes wrong.

I understand why Dudley did this: he had just enough ability and access to materials and equipment to do it, but did not have the cash to pay the usual professionals to do so.

In spite of Dudley’s success, should this approach become a thing? I definitely don’t think it should; there is simply too much risk. Too many things can go wrong, and grave mistakes could be made.

There’s a reason for professional disciplines, and it’s a lot more than just getting a job done. It’s getting it done properly, no matter what the circumstances.

Via Amos Dudley