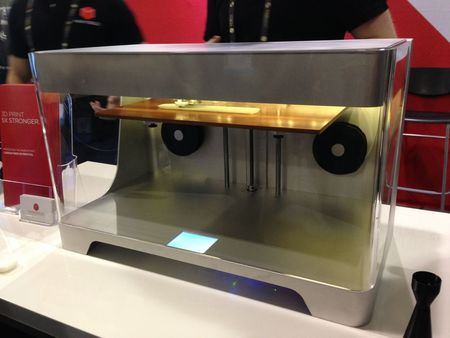

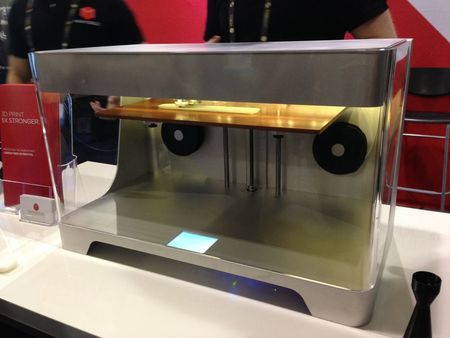

We took a look at a surprise 3D printer unveiled this week: Mark Forg3D’s Mark One, after a year of secret development work. At a glance, it looks like any other personal-sized 3D printer, albeit with a very slick metal case. But then you look at what’s being printed.

Carbon Fiber.

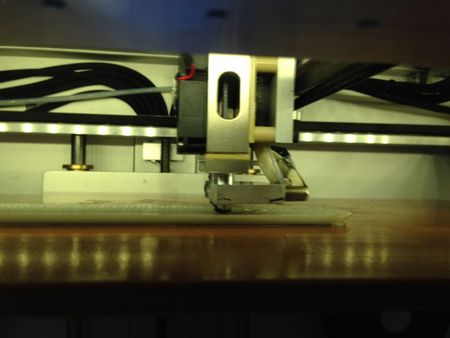

Yes, this device can actually 3D print carbon fiber. We believe it is the very first 3D printer capable of producing objects made from carbon fiber, a wondrous material with extreme strength and very light weight. The extruder imaged above is capable of 3D printing not only carbon fiber, but also PLA, Nylon and even Fiberglass!

Carbon fiber produced by the Mark One is said to be 20X stronger than ABS – and even slightly stronger than aluminum! To put this in perspective, imagine a chunk of ABS 20mm thick – it’s as strong as 1mm of carbon fiber.

We were surprised to learn that you don’t need to 3D print objects made entirely of carbon fiber. Instead, objects can be massively strengthened merely by adding a few layers of carbon fiber. Mark Forg3D’s slicing software permits easy editing of each layer to specify precisely where you’d like some carbon. This is a unique feature among lower-end 3D printers – and it economizes your use of carbon fiber, too.

According to Mark Forg3D, a typical part would be printed in a combination of nylon and carbon fiber. You can, for example, print such a part in nylon for a cost of USD$18 as a prototype and then print a final version in carbon for around USD$27.

The Mark One has another very unique feature: it’s removable print bed has capabilities we’ve not seen before. It’s a thick piece of acrylic that’s fastened to a robust metal armature with magnets. By shaping the magnets and their receptacles, Mark Forg3D claims the bed can be consistently reinstalled within 10 microns of its original position! This means you can successfully pause a print, remove/replace the bed and resume printing. You can be sure they’ve been applying for several patents. Oh yeah, this bed is so accurately placed that it requires No Leveling!

The Mark One has a very healthy 305 x 160 x 160mm build volume and can manage up to 0.1mm accuracy. The build chamber is not heated, but it is “draft blocking”.

The device is presently a prototype only, but Mark Forg3D says they’ll begin pre-sales soon, with an expectation of selling the Mark One on June 1st at an unexpectedly low price of USD$5,000.

Via MarkForg3D