One of the annoying things about 3D printing is the length of time it takes to produce objects. Unlike a printed 2D page, which is created in a single sweep of the inkjet, 3D objects have many layers that sometimes take hours to print. Clearly, a way of speeding things up would be desirable.

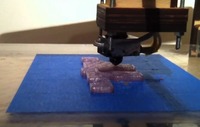

One of the annoying things about 3D printing is the length of time it takes to produce objects. Unlike a printed 2D page, which is created in a single sweep of the inkjet, 3D objects have many layers that sometimes take hours to print. Clearly, a way of speeding things up would be desirable. The folks at Ultimaker, an up and coming hobby 3D printer, have done something about this by experimenting with increasing the speed of their device. They cranked up the feedrate (the speed of extrusion) to an astonishing 300 mm/second (this is contrasted with a conventional rate of around, say, a mere 30 mm/second) and also raised the travel rate (the speed of movement while not extruding) to near-warp-speed of 350 mm/second!

How did they achieve this record-breaking speed? First they used PLA plastic instead of ABS, as they found “flowrate issues occasionally and at high speeds it bonds less to the previous printed layer”. Also they believe this approach might not be successful for all shapes.

This is what we love about 3D printing: every week someone makes it a whole lot better.

Via Ultimaker