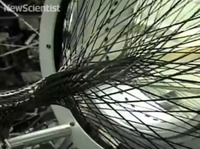

New Scientist reports on an innovative parts-making process invented by Lexus. It’s a kind of futuristic 3D Loom that essentially “weaves” parts together. The circular device pulls a series of carbon fibres into a desired shape and is capable of “weaving” highly complex parts much faster than traditional techniques. Curves, varying thicknesses and dimensions are all possible with this approach. Once a part is “weaved”, it is then soaked in resin to finish and solidify the item.

New Scientist reports on an innovative parts-making process invented by Lexus. It’s a kind of futuristic 3D Loom that essentially “weaves” parts together. The circular device pulls a series of carbon fibres into a desired shape and is capable of “weaving” highly complex parts much faster than traditional techniques. Curves, varying thicknesses and dimensions are all possible with this approach. Once a part is “weaved”, it is then soaked in resin to finish and solidify the item.  This approach is completely different from other common 3D printing techniques, and is likely able to make certain types of items that other techniques may not. However, it seems rather complex if you watch the video and probably will remain a unique process suitable for making overly expensive sports cars. We probably won’t see a MakerWeave anytime soon.

This approach is completely different from other common 3D printing techniques, and is likely able to make certain types of items that other techniques may not. However, it seems rather complex if you watch the video and probably will remain a unique process suitable for making overly expensive sports cars. We probably won’t see a MakerWeave anytime soon. Via New Scientist