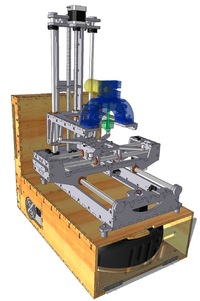

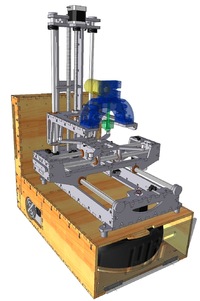

Charles Guan is the mastermind behind the experimental Make-A-Bot, a new 3D printer of (mostly) his own design. Based on a combination of MakerBot and RepRap tech, this interesting printer makes extensive use of water-jet cut aluminum, with acrylic and wooden components as well.

Charles Guan is the mastermind behind the experimental Make-A-Bot, a new 3D printer of (mostly) his own design. Based on a combination of MakerBot and RepRap tech, this interesting printer makes extensive use of water-jet cut aluminum, with acrylic and wooden components as well. The printer uses a MakerBot Mk5 plastruder, but has a different build area (6x6x6 inches) and is capable of reasonably accurate prints due to its incredibly solid design. The builds take place on a “Custom thermally regulated build surface”. Charles’ testing has shown that the device is capable of quality printing at a startling 55mm/s!

Charles says:

DIY 3-dimensional additive fabrication and personal manufacturing are rapidly expanding areas of exploration for hobbyists, amateur engineers, tinkerers and Maker-folk. The development aims to provide an alternative or complement to capital-intensive mass manufacturing for individual-level consumption, and also aims to empower the individual in the design and creation of their own goods. Because of the involvement of many demographics including said amateur engineers and hobbyists in this “research”, potential breakthroughs for the additive fabrication industry as a whole are also promising. As the technology continues to evolve on a grassroots level, the quality of products and streamlining of the process should approach or overtake levels achieved by commercial additive fabrication machines while remaining accessible to persons interested in pursuing engineering as a hobby or profession.I mean, besides all that, I want my own 3d printer.

Be sure to watch the videos of this fascinating printer.