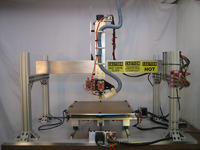

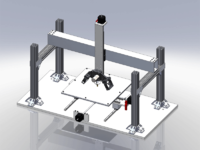

Troubled by a tiny build chamber size? Anxious to print those 13 inch custom-designed sandals in one operation? You might want to get your hands on Jim Smith’s new project at Grass Roots Engineering, where he’s designing a low-cost 3D printer with an incredible build volume of 403x403x322mm (15.86×15.86×12.70″). In addition to the build volume, there are more interesting features:

Troubled by a tiny build chamber size? Anxious to print those 13 inch custom-designed sandals in one operation? You might want to get your hands on Jim Smith’s new project at Grass Roots Engineering, where he’s designing a low-cost 3D printer with an incredible build volume of 403x403x322mm (15.86×15.86×12.70″). In addition to the build volume, there are more interesting features:- Can use different print heads by adjusting the height of the Z-axis

- Interchangeable print surfaces for different applications

- Multiple print head attachment points

- Powered fume removal system

- Print head-mounted cooling fans

- Linear bearings for smooth (and large) operation

This design is different from other kit printers we’ve seen, and it looks promising. We’re going to watch developments to see how this experiment proceeds. If successful, it might influence the design of future 3D printers.

Designer Jim Smith has been working in the 3D print zone for some years, including a stint as the Mechanical Systems team leader for the Fab@Home project, so you can be sure this is a very serious hardware design.

Designer Jim Smith has been working in the 3D print zone for some years, including a stint as the Mechanical Systems team leader for the Fab@Home project, so you can be sure this is a very serious hardware design. But can you get one of these for yourself? Not yet, as Jim is still in the design and experimentation stage. But he’s promised to show us what happens. He says:

I created Grass Roots Engineering so I could share the developments and continual improvements of my 3D printing machines.

One question we have, beyond the engineering of the device, is its name. A device such as this deserves a very cool name. Any suggestions?

Via GrassRootsEngineering (Hat tip to Jim, Jeff and Rob)