If the size of your 3D printer’s build chamber is too small, the answer is obvious: break your object into a series of smaller parts, print and assemble them. That or buying a bigger printer.

If the size of your 3D printer’s build chamber is too small, the answer is obvious: break your object into a series of smaller parts, print and assemble them. That or buying a bigger printer.  But let’s turn this around: what if you don’t know how big your object is, and you just print the parts? That’s what Gernot Oberfell and Jan Wertel did when they took their successful Fractal.MGX design and spun it into the new Module.MGX design. It’s a modular table system, based on standard interlocking units that can be assembled in an infinite number of ways.

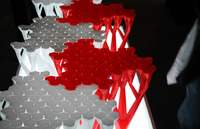

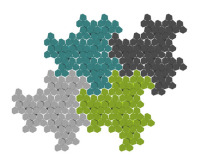

But let’s turn this around: what if you don’t know how big your object is, and you just print the parts? That’s what Gernot Oberfell and Jan Wertel did when they took their successful Fractal.MGX design and spun it into the new Module.MGX design. It’s a modular table system, based on standard interlocking units that can be assembled in an infinite number of ways. The base component design:

draws inspiration from research into geometries with self-similarity e.g. fractals, patterns that occur in nature and proportional systems like the golden section. With its steep angled walls and hollow structure, the Module.MGX minimizes waste, saves energy during the production process and makes production more cost effecctive. Due to its size and shape, the table can be used alone or with an infinte number placed seamlessly next to each other.

The modular approach is very interesting, and certainly could be attempted on home 3D printers. Who knows what kind of large-scale modular designs may appear?