On your 2D paper printer, the print job is usually complete by the time you get your butt out of the chair and stroll over to the printer. Not so with a 3D printer, where you often must wait for many minutes, or even hours for a job to complete. When it’s done, you’ve probably gone for dinner and the newly printed model sits patiently in the build chamber, waiting for you to remove it so that the next printout can commence.

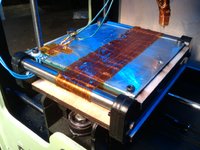

On your 2D paper printer, the print job is usually complete by the time you get your butt out of the chair and stroll over to the printer. Not so with a 3D printer, where you often must wait for many minutes, or even hours for a job to complete. When it’s done, you’ve probably gone for dinner and the newly printed model sits patiently in the build chamber, waiting for you to remove it so that the next printout can commence. But this may not be the case much longer, if experiments by NYC Resistor member Charles Pax succeed. He’s designing a conveyer belt system that overlays the normally calm build platform. In other words, when the build is complete (and sufficiently solidified) a software command triggers the conveyer belt to shoot the model out of the build chamber into a hopefully conveniently placed basket. Sounds much like the output tray on your laser printer, doesn’t it?

The implication of this could be huge; it means that a MakerBot could run continuously printing several items unattended, if all goes well. You’ll wake up in the morning and fish seventeen flanges from your model basket, ready for use. Just make sure you have a sufficiently large basket and one heck of a large spool of ABS.

Via MakerBot and Charles Edward Pax

Very cool!!!!

Very cool!!!!