The fundamental premise of 3D printing is layers. We add them a fraction of a millimetre at a time, be it with plastic, powder or some expensive goop, it is the basis of all 3D printing. Even the software assumes this is the case as it slices our 3D models into layers suitable for printing.

The fundamental premise of 3D printing is layers. We add them a fraction of a millimetre at a time, be it with plastic, powder or some expensive goop, it is the basis of all 3D printing. Even the software assumes this is the case as it slices our 3D models into layers suitable for printing. And now we hear of a completely different approach: Folding. Technology Review’s article describes a technique where:

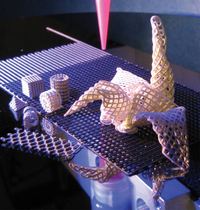

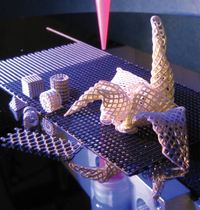

The technique involves making latticed sheets from ceramic ink, then folding and heating these sheets to create intricate shapes. The method could be used to make lightweight parts for aerospace applications, complex scaffolds for tissue engineering, and filters and catalysts for industrial chemical production.

The special inks contain mixes of ceramic or metal particles that fuse together when sufficiently heated. This part of the technique is very familiar, as it is how 3D metal printing is currently done.

We’re wondering how this technology could become widespread, and we believe the challenge is in the software. While it is easy for any arbitrary 3D model to be sliced into Z-layers for printing, it’s quite another matter to compute the optimum folding pattern, particularly on a complex model. In the end it might be simpler to combine the two techniques together into a layered-folding device that takes advantage of both approaches. Models could be printed in layers, but portions could be folded to overcome support difficulties.

Via Technology Review (Hat tip to Charlie)

I often use Pepakura Designer for not-so-rapid prototyping projects: it makes very good foldable flat patterns from 3D models (3DS or OBJ) as long as the geometry is not too complex. And it’s pretty affordable at $38.

http://www.tamasoft.co.jp/pepakura-en/

I often use Pepakura Designer for not-so-rapid prototyping projects: it makes very good foldable flat patterns from 3D models (3DS or OBJ) as long as the geometry is not too complex. And it’s pretty affordable at $38.

http://www.tamasoft.co.jp/pepakura-en/