Did you ever take a very close look at your fingers? They are incredibly complex machines, with not only shape and texture, but also motion. Imagine if fate caused the loss of one or more of them?

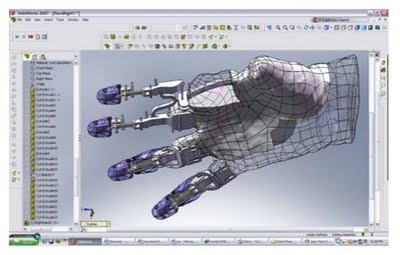

There are solutions today, such as those produced by Didrick Medical, who make a kind of finger-harness that fits over the hand and implements an “active-function artificial finger prostheses”. The design permits a variety of finger loss scenarios to be resolved. This is their “X-Finger” product.

But the problem is in the build. Turns out that everyone’s hands and fingers are pretty much unique. Who knew?

Didrick Medical’s approach is to custom design each and every X-Finger to perfectly match the recipient. However, as you might suspect, the measurements are very complex, tedious and time consuming.

Enter 3D Laser Scanning from GKS Global Services, who used their equipment and software to gather the necessary 3D modelling data much more quickly than had been done manually. The scanning is done from a cast of the hand, presumably to avoid “twitches”.

Once the 3D model is successfully captured and tweaked, SolidWorks takes over and the production process continues as normal. And the fingerless get new fingers.

Via LaserDesign