Last December we introduced Huntsman Advanced Material’s unique laser sintering process, in which they use as much as 40,000 light pixels simultaneously. This approach greatly speeds up the laser sintering process, as it is traditionally done on a vector basis – a single pixel at a time.

But recently an article in European Plastics News reveals additional information about the process:

- A Micro Light Switch collimated UV light exposure system drives the Huntsman device

- The build material used is a proprietary ultraviolet light-curable Araldite resin

- No lasers or MEMS (micro electromechanical systems for positioning tiny mirrors) are used

- The UV light is always oriented 90 degrees to the build material’s surface

- Build speeds are “up to three times faster than an SLS (selective laser sintering) machine when benchmarked against a hearing aid reference part.”

- Some customers are testing the machine at this moment

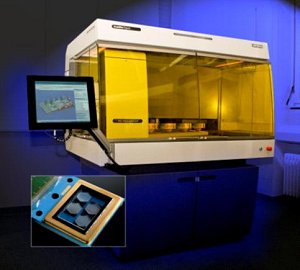

- The Digitalis system has a build chamber of 0.65m x 0.37m x 0.60m, and the entire machine weighs approximately 2,000Kg

- Only one material color is available, but evidently more colors are in the works

Huntsman’s design is certainly a novel approach; parallel printing is likely the way rapid 3D printing will have to be done in the future.