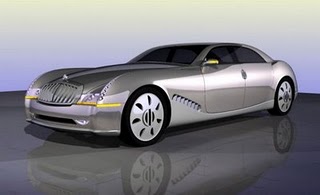

DiMora Motors is using this new approach to build the startling 1200-HP motor on their new USD$2M Natalia SLS 2 sport luxury sedan.

The new process appears to be a variation of 3D printing with a different media: sand! Of course, the final engine is not 3D printed, but its casts and molds were. According to the press release:

According to Dan Maas, Director of Business Development for ProMetal, “This revolutionary ProMetal RCT process allows design freedoms, heretofore never available to the casting designer or the foundry. Removing the requirements for parting lines, draft angles and providing undercuts is just the tip of the iceberg,” asserted Maas. “Providing nested cores, spiral vents, volute shapes, integration of multiple components, in-situ cores, and unique rigging geometry to minimize turbulence are design features that are being utilized today by advanced companies.”

One wonders what things may happen when engine designers catch on and begin traveling through a design space with far fewer restrictions.

Vroom!

Via PRLog

Great stuff from you, man. Ive read your stuff before and you're just too awesome. I love what you've got here, love what you're saying and the way you say it. You make it entertaining and you still manage to keep it smart. I cant wait to read more from you. This is really a great blog.Happy New Year 2011