Tim Pickup posted a very interesting report on investigations taking place at the Centre for Fine Art Print Research in Bristol, UK. In addition to ideas regarding advanced scanning, modeling and the printing of “impossible” objects such as Klein Bottles, one item caught our eyes: surface quality. Some of the highlights:

Tim Pickup posted a very interesting report on investigations taking place at the Centre for Fine Art Print Research in Bristol, UK. In addition to ideas regarding advanced scanning, modeling and the printing of “impossible” objects such as Klein Bottles, one item caught our eyes: surface quality. Some of the highlights:

- The researchers apparently have been experimenting with different types of home-brewed media powder for their ZCorp 310 and 510, combining ceramics in a way that can be 3D printed, then fired in a traditional pottery sense.

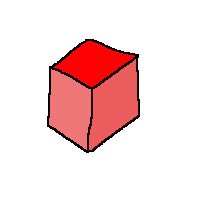

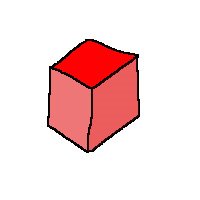

- Color saturation appeared to be different depending on the axis of view. The cube pictured above tells the story – deeper saturation on the horizontal plane, while less on the vertical.

- Curved surfaces did not exhibit the same issue, so it is thought that a perfectly flat surface may result in over-saturation.

Color quality is clearly another consideration for those purchasing 3D equipment.

Via Tim Pickup

Any idea what this “homebrew” might consist of?