There’s a new volumetric 3D printer on the market you can now purchase.

Volumetric 3D printing is an entirely new way of 3D printing that doesn’t involve layers: the objects form all at once at incredible speed. The process involves projecting light patterns into a tank of clear photopolymer resin.

One way to understand volumetric approaches is that it is like printing in true “3D”, while current layered processes like FFF, MSLA, LBPF and others are just “2D”, stacked together.

The result is that 3D prints can be obtained extraordinarily fast — some prints literally take only seconds to complete. I’ve seen this process take place in person, and it’s quite amazing: the build chamber glows brightly for a moment or two, and then it’s all done. Near-instant printing!

There are a few companies pursuing volumetric 3D printers, and one of them is Germany-based Xolo.

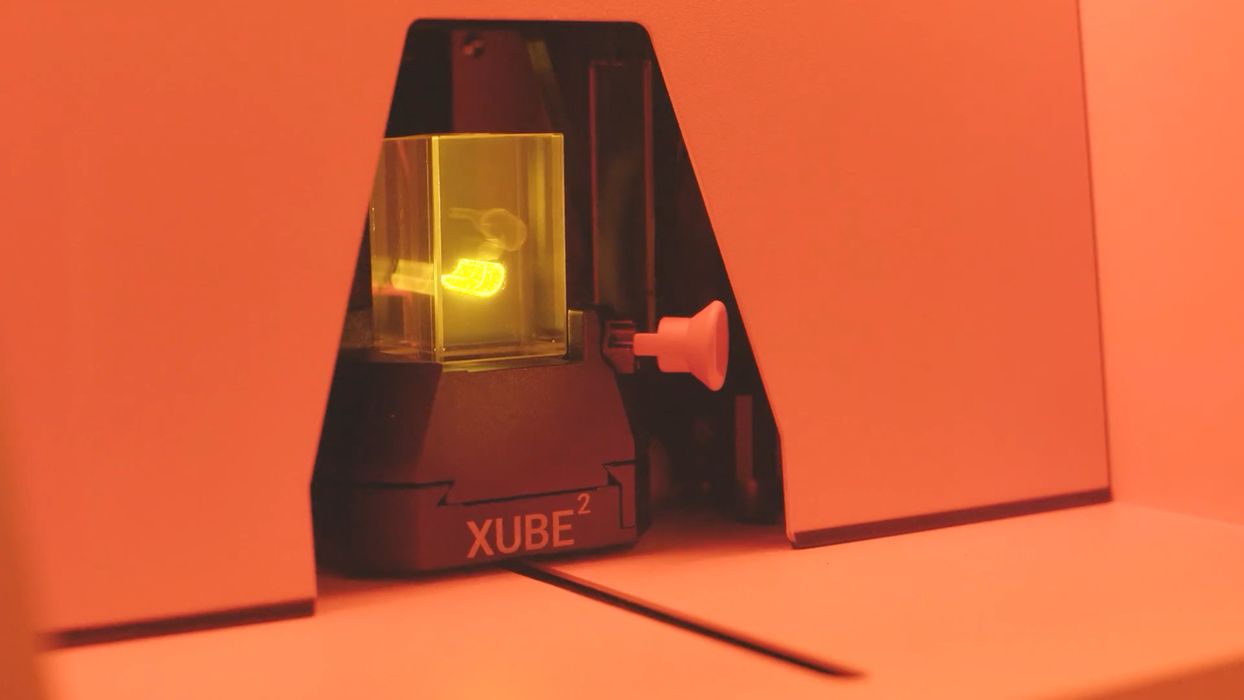

They produce the Xube, which was the first commercial volumetric 3D printer on the market, as far as I can tell. This week they announced availability of an upgraded device called the Xube².

The Xube² uses Xolo’s specific volumetric 3D printing process, which they call “Xolography”.

The build volume possible with Xolography is a bit small, mainly due to the ability of projections to penetrate deep into a vat of resin. Because of this, there are specific applications that have emerged as best for the original Xube. Xolo explains:

“This method is ideal for printing biocompatible materials and hydrogels, as well as technical objects, like optical elements with smooth surfaces. High-viscosity materials can be printed without support structures, allowing for isotropic material properties and high-performance direct oligomer printing. This makes Xolography particularly useful for scientific research and advanced manufacturing.”

Specifications include variable build volumes and resolutions possible with the Xube²:

- 30 x 50 x 80 mm at 0.015mm

- 20 x 35 mm at 0.010mm

- 10 x 17 mm at 0.005mm

The system doesn’t use resin tanks like other 3D printers, but instead uses a “cuvette”. This is a small glass tank pre-loaded with the resin.

This is similar to other optical 3D printing processes, where higher resolution can be obtained by scaling down the projection area.

Xolo has improved the Xube² with a few new features. One is a way to quick-change cuvettes for near-immediate material swaps. This also allows changes between 405nm and 385nm resins, which is also accommodated by switchable light sheets.

The new machine can also fully control thermal aspects of the system, which Xolo said are critical to tune some of the unusual materials used in the Xube².

Finally, they’ve also completely redesigned the software that drives the Xube², with an intent to provide full flexibility for the operator to customize the 3D printing process.

The Xube² is not for everyone, but for those applications that require these types of materials, small build volume and resolution, the Xube²’s print speed could be quite an advantage.

Via Xolo