There is big news from Xolo: They are partnering with Swarovski, the famous crystal provider.

Xolo, if you’re not familiar with them, is a German company that has developed a commercial volumetric 3D printer. This device uses an entirely different resin process to produce objects nearly instantly. It’s like a reverse CT scan, where light is projected from all directions into a transparent vat of resin. The object forms not in layers, but all over at once, providing massive speed increases.

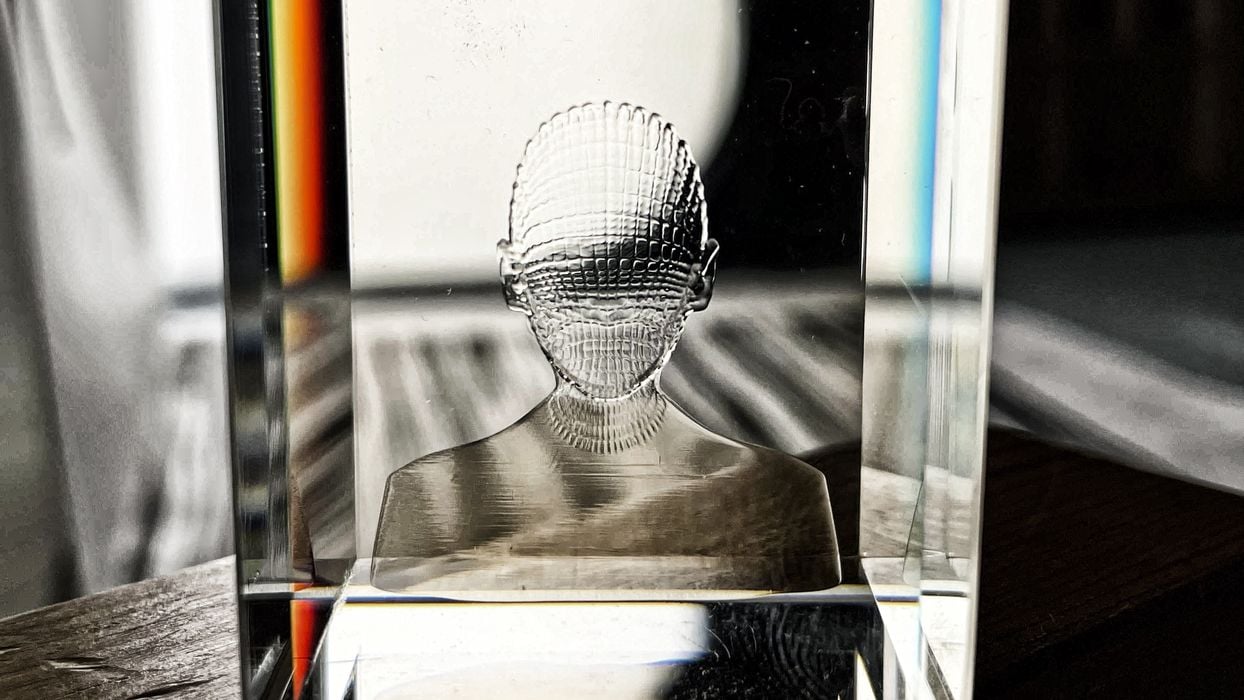

The partnership will involve using Xolography to produce unique crystal glass products for Swarovski. xolo explains:

“xolo’s cutting-edge volumetric printing technology, Xolography, allows for the creation of intricate glass components with unprecedented clarity and detail. This collaboration underscores Swarovski’s commitment to innovation with a focus on consumer needs. The project has been co-developed with the group of Professor Paolo Colombo from the University of Padova.”

This is quite interesting, because traditional techniques for making crystal glass objects involves several manufacturing steps:

- Glass forming in a furnace

- Molding or Blown glass

- Coarse Cutting and Grinding

- Fine cutting and patterning

- Polishing

- Engraving

- Chemical etching

If that sounds like a lot of effort, it is. That’s one of the reasons why crystal items are so expensive: they are hard to make.

Now consider what Xolography might offer: they may be able to directly print final objects and skip most of these steps. And, they can print almost instantly. Printing with Xolography takes only a minute or so, as I’ve personally witnessed.

Another major benefit for Swarovski is that it maybe possible to produce crystal objects that are impossible to make using traditional methods. This was the case in aerospace, automotive and other industries, so it’s likely to repeat in the crystal glass market.

Since glass does not appear to be one of Xolo’s standard materials, it is possible the two parties will be developing a new glass-based resin for this purpose. It’s also possible that the final prints might have to undergo a sintering step to remove the polymer and form the final crystal glass object.

It may be that this could be a huge market for Xolo. They write:

“As this collaboration progresses, both Swarovski and xolo anticipate setting a new industry standard that could eventually be adopted across various sectors of glass manufacturing. This initiative is not just a transformation of technique but a redefinition of the material’s role in modern design and functionality.”

Startups like xolo often don’t know where the optimal application for their technology might be, and it takes time for companies to explore the space and identify the best prospects. It could be that xolo has hit on something quite big with their partnership with Swarovski.

Via xolo