SPONSORED CONTENT

PCBWAY is best known as a printed circuit board (PCB) prototyping service, but did you know they also provide injection molding services?

They’ve added 3D print and CNC milling services, but injection molding is also now a key service for the company.

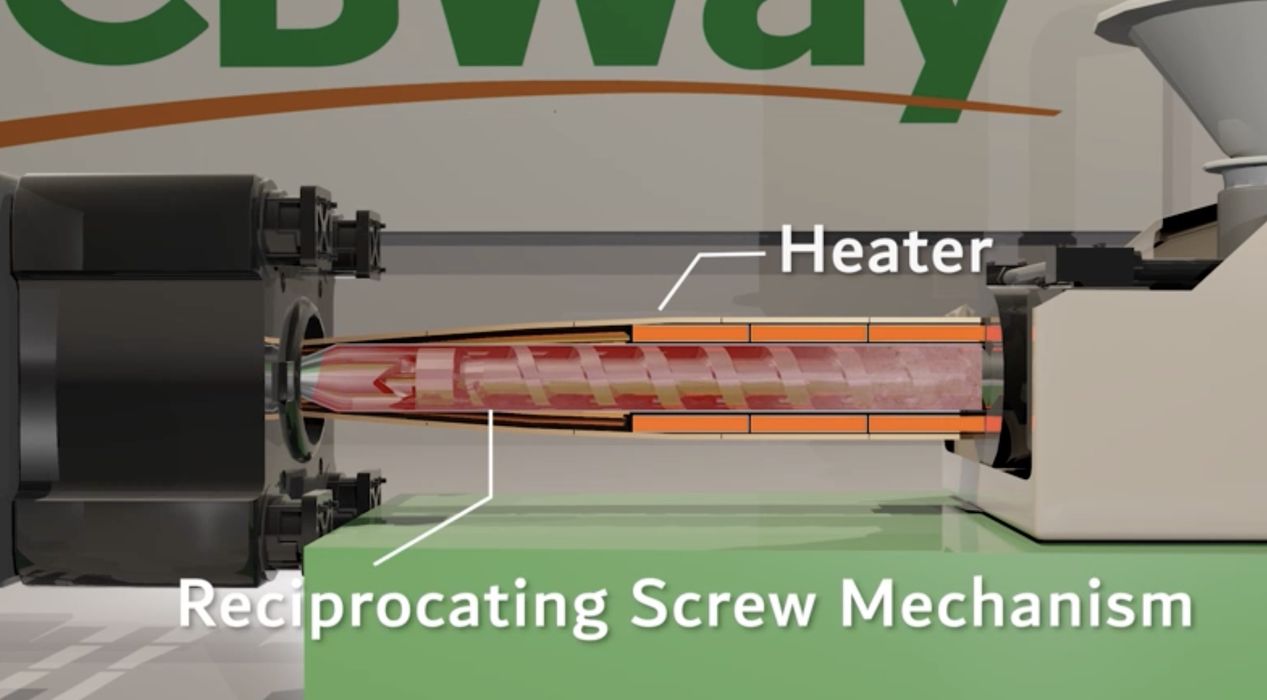

Injection molding is different from 3D printing in that it can be less expensive to produce larger quantities of parts. That’s because the process involves creating a reusable mold, which then is used to quickly and repeatedly cast precision parts.

Unlike 3D printing, injection molded parts can have perfectly smooth surfaces because the polymer matches the surface of the mold. 3D printing invariably has visible layer lines that change the look and feel of parts.

Another key difference is the choice of materials. Injection molding simply requires a mold and a softened polymer; it’s much simpler than 3D printing. There are thousands of possible materials for injection molding, and PCBWay’s injection molding service offers a choice from a list exceeding 100 options. They’ve chosen the most popular materials to provide a wide range of engineering properties, ranging from rigid, to rubber-like, to flexible and even some foam options.

If you already have a 3D printer, as do many Fabbaloo readers, why would you consider using injection molding? There are several reasons that can be considered.

Injection molding parts can be stronger than equivalent 3D printed parts. This is because 3D printed parts tend to be weaker along the layer lines. Injection molding does not have any lines, as the material flows inside the mold and becomes isotropic.

Injection molded parts can have superior surfaces due to the high quality of the mold, which is typically made from precision milled metal.

Injection molded parts can be made from materials that cannot be 3D printed.

There are some considerations, however. The geometry of injection molded parts must be compatible with the mold: after injection, the part must release from the mold, so overhangs and loops cannot be used. Certain complex geometries can only be made with 3D print technologies, but most other designs should be compatible with injection molding.

Aside from these advantages and considerations, why would a 3D printer operator want to use injection molding? It’s usually because of a need to move to the production of a part.

The typical lifecycle of a part is to first undergo a series of prototypes to optimize and finalize the design. This is best done with 3D print technology, as there is no need to produce a new mold for each iteration.

However, once the design is finalized and quantities of parts are required, injection molding should be considered. If the quantity of parts is sufficiently large, then it will be less expensive to use injection molding than 3D printing the same quantity of parts. This is especially true if the number of parts required is very large. PCBWay’s injection molding service can handle as many as 500,000 units, which is not feasible on a 3D printer.

How much does PCBWay’s injection molding service cost? That depends on several factors. One is the cost to produce the mold for the design, which varies according to the geometry and size. Another factor is the pricing of different injection molding materials. Finally, there’s the number of parts to be produced. PCBWay can guide you through the pricing process so you understand the full cost of a given injection molding job.

If you’ve designed a 3D printed part that you want to replicate at scale, injection molding is the way to go, and PCBWay offers a capable service to do so.

Via PCBWay