Charles R. Goulding and Preeti Sulibhavi consider how Rheinmetall and Auterion are transforming modern warfare with AI-driven, 3D-printed autonomous drone systems that redefine battlefield strategy and efficiency.

The rapid evolution of modern warfare has highlighted the transformative role of technology, particularly in unmanned aerial systems (UAS). As the demand for advanced, autonomous drone solutions grows, Germany’s largest defense company, Rheinmetall, is collaborating with Auterion, a Virginia-based software company, to pioneer a new era of unmanned, autonomous drone systems. These systems are not only designed to operate independently but also to communicate and collaborate seamlessly with one another, creating a powerful, interconnected network of aerial units. This partnership leverages cutting-edge advancements in artificial intelligence (AI) and 3D printing, technologies that are revolutionizing drone development and deployment. In this article, we explore the significance of this collaboration, its technological underpinnings, and its broader implications, particularly against the backdrop of the Ukraine conflict, where over 200 distinct drone systems are currently in operation.

The Strategic Importance of Unmanned Drone Systems

Drones have become a cornerstone of modern military operations. Their ability to perform reconnaissance, surveillance, and strike missions without risking human lives makes them invaluable on the battlefield. However, the sheer diversity of unmanned systems—especially in conflicts like Ukraine—has highlighted the challenges of interoperability and efficiency. Currently, the absence of standardized platforms often leads to logistical bottlenecks and reduced operational effectiveness.

This is where Rheinmetall and Auterion’s collaboration stands out. By developing autonomous drone systems that can communicate and coordinate with one another, they aim to overcome these challenges, ensuring enhanced adaptability and streamlined operations. Such advancements are particularly crucial in dynamic conflict zones, where real-time decision-making can mean the difference between mission success and failure.

Rheinmetall and Auterion: A Synergy of Expertise

Rheinmetall, a global leader in defense technology, brings decades of expertise in engineering, weapons systems, and military-grade hardware. Fast-growing Rheinmetall is targeting US$21.2 billion in sales for 2024.

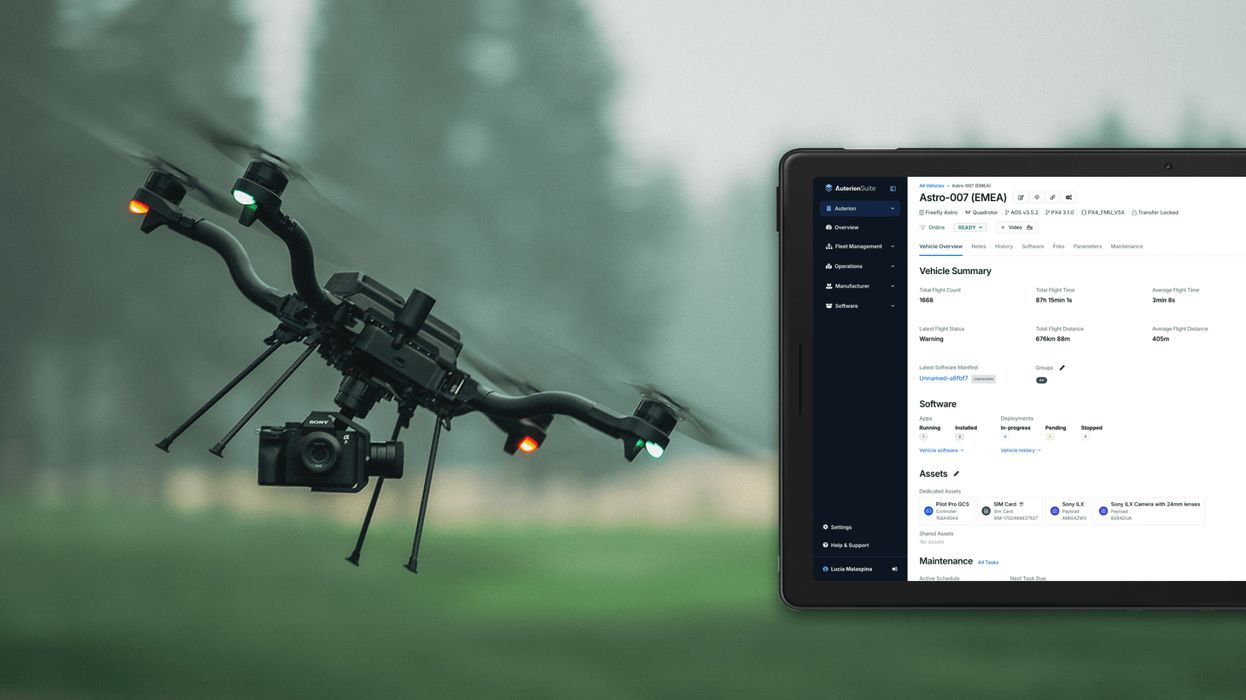

Auterion, on the other hand, is renowned for its open-source drone software ecosystem, including its PX4 autopilot system, which is widely used in the civilian and military drone sectors. Together, these companies are integrating Rheinmetall’s robust hardware capabilities with Auterion’s sophisticated software solutions to create next-generation drone systems.

One key focus of this partnership is the development of autonomous swarming technology. Swarming involves multiple drones working collaboratively to achieve complex objectives, such as reconnaissance over a wide area or coordinated attacks on enemy assets. This requires advanced communication protocols, real-time data sharing, and decision-making capabilities—all of which are being enabled by AI and reinforced by innovative manufacturing methods like 3D printing.

Artificial Intelligence: The Brain Behind Autonomous Drones

Artificial intelligence is the linchpin of the Rheinmetall-Auterion collaboration. AI empowers drones to process vast amounts of data in real-time, enabling them to make decisions independently. For example, AI-driven drones can identify and classify targets, adjust flight paths to avoid threats, and optimize resource allocation during missions.

In the context of swarming, AI allows drones to operate as a cohesive unit. Each drone within the swarm can share information with its counterparts, enabling collective intelligence. For instance, if one drone identifies a target, it can relay this information to the entire swarm, allowing other drones to adapt their strategies in response. This level of coordination drastically improves efficiency, reduces redundancy, and enhances mission success rates.

AI also plays a critical role in ensuring interoperability between different drone systems. Given the variety of aerial platforms currently in use, especially in Ukraine, the ability of Rheinmetall-Auterion drones to communicate with legacy systems is a game-changer. Their AI algorithms can translate and interpret data across multiple formats, bridging the gap between disparate technologies.

3D Printing: Accelerating Innovation and Deployment

While AI provides the brains, 3D printing is revolutionizing the physical construction of drones. Traditional manufacturing methods are time-consuming and costly, particularly for custom or limited production runs. 3D printing offers a faster, more cost-effective solution, allowing Rheinmetall and Auterion to prototype and produce drone components with unparalleled precision and speed.

One major advantage of 3D printing is its ability to create lightweight, durable structures optimized for aerial performance. For instance, drones can be designed with intricate geometries that maximize aerodynamics while minimizing weight, leading to improved flight efficiency and longer operational ranges. Moreover, 3D printing enables on-demand manufacturing, which is particularly valuable in conflict zones. Broken or damaged drone parts can be printed and replaced on-site, reducing downtime and ensuring mission continuity.

A notable example is the use of 3D printed payload bays that can be customized for specific missions, such as carrying surveillance cameras, sensors, or even small munitions. This adaptability enhances the versatility of drone systems, allowing them to be tailored to a wide range of operational requirements.

The Ukraine Factor: Lessons from the Battlefield

The ongoing conflict in Ukraine has underscored the critical role of drones in modern warfare. Both sides have employed a staggering variety of UAS, from off-the-shelf quadcopters used for reconnaissance to advanced combat drones capable of delivering precision strikes. However, the lack of standardization has often led to inefficiencies and operational challenges.

Rheinmetall and Auterion’s work addresses these issues head-on. Their autonomous drone systems are designed to operate seamlessly in mixed environments, where compatibility with existing systems is essential. For example, a Rheinmetall-Auterion drone could potentially share battlefield intelligence with a legacy system already deployed in the region, creating a unified operational picture.

Furthermore, the resilience provided by 3D printing is particularly relevant in Ukraine, where supply chains are frequently disrupted. The ability to manufacture critical drone components locally ensures that forces remain operational even in the face of logistical challenges.

The Broader Implications of AI and 3D Printing in Defense

The integration of AI and 3D printing extends beyond drones, offering transformative potential across the defense industry. Autonomous systems powered by AI can enhance situational awareness, reduce human workload, and improve decision-making in complex scenarios. Meanwhile, 3D printing enables rapid prototyping and production of everything from vehicle parts to medical supplies, ensuring adaptability in ever-changing operational landscapes.

For Rheinmetall and Auterion, these technologies represent more than just tools—they are the foundation of a new defense paradigm. By combining AI-driven autonomy with the versatility of 3D printing, they are setting new benchmarks for efficiency, scalability, and innovation in military technology.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes are typically eligible expenses toward the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software can also be an eligible R&D expense. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The partnership between Rheinmetall and Auterion is a testament to the transformative power of collaboration in advancing military technology. By harnessing the capabilities of AI and 3D printing, these companies are creating drone systems that are not only autonomous and interoperable but also highly adaptable to the demands of modern warfare.

As the world watches the ongoing developments in Ukraine, it is evident that the battlefield of the future will be dominated by intelligent, interconnected systems. Rheinmetall and Auterion are at the forefront of this evolution, paving the way for a new era of unmanned warfare where efficiency, precision, and adaptability are paramount. Their innovations promise to redefine what is possible in defense technology, ensuring that military forces are better equipped to meet the challenges of the 21st century.