Understanding the differences can help engineers select the right approach for specific challenges.

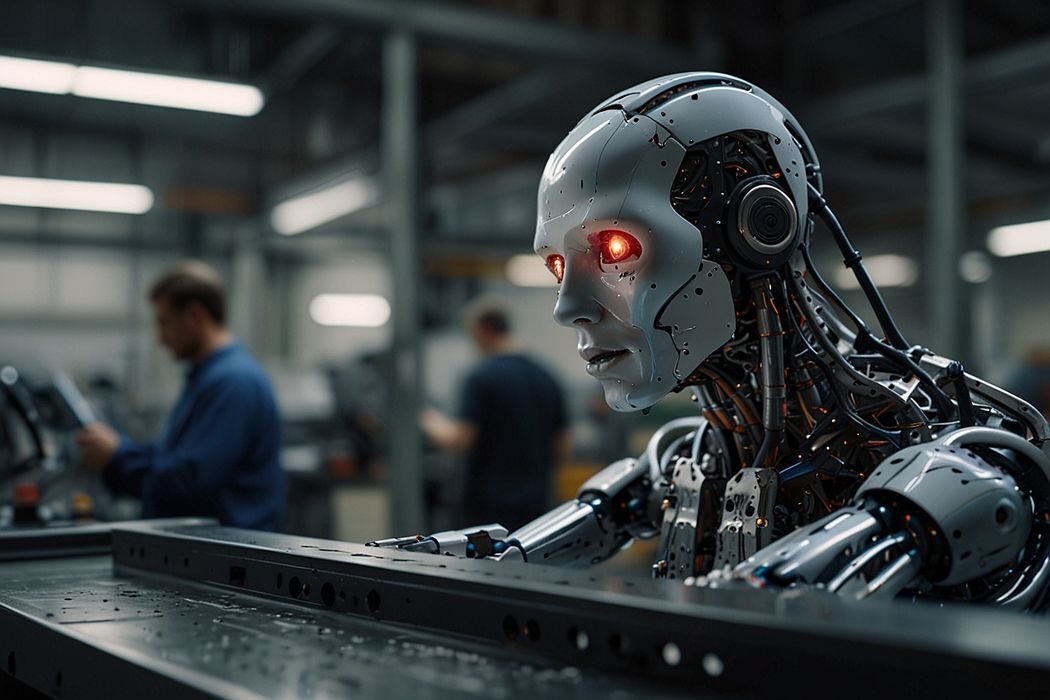

In manufacturing, different types of AI serve distinct purposes. Understanding the differences between Agentic AI, Causal AI, and Large Language Models (LLMs) can help engineers select the right approach for specific challenges.

Agentic AI: autonomous decision-making

Agentic AI refers to AI systems that act autonomously based on goals, real-time data, and feedback loops. In manufacturing, this can be seen in self-optimizing production lines, automated quality control, and predictive maintenance. Unlike traditional automation, Agentic AI can adapt to changing conditions and make independent operational decisions without human intervention, improving efficiency and reducing downtime.

Causal AI: understanding cause and effect

Causal AI goes beyond pattern recognition by identifying cause-and-effect relationships in complex manufacturing systems. This AI type is valuable in root cause analysis, process optimization, and failure prediction. Unlike conventional machine learning, which correlates data, Causal AI determines why failures or inefficiencies occur, enabling engineers to implement targeted solutions rather than just responding to symptoms.

LLMs: processing language and documentation

Large Language Models (LLMs), such as GPT-based AI, specialize in natural language processing (NLP). While not directly involved in factory operations, LLMs help automate documentation, generate maintenance reports, assist with troubleshooting, and provide AI-driven technical support. They can summarize engineering papers, create standard operating procedures (SOPs), and improve communication across teams.

Choosing the right AI

Each AI type complements manufacturing processes in unique ways, leading to smarter, more efficient operations.

Manufacturing Example: Causal AI vs. Agentic AI

Use Case: Predicting and preventing machine failures.

How It Works: A factory uses causal AI to analyze historical sensor data from machines.

Instead of just identifying correlations (When temperature rises, breakdowns occur), it determines the cause (Excess vibration due to misalignment leads to overheating, which causes failure).

This allows engineers to intervene proactively by fixing misalignment before a breakdown happens.

Use Case: Autonomous production line optimization.

How It Works: An agentic AI system monitors production efficiency in real-time and autonomously adjusts machine settings for optimal output.

If a machine slows down, the AI dynamically reallocates work to other machines without human intervention.

It learns from past production data and adapts continuously to maximize efficiency while minimizing waste and energy use.

Key Differences:

Causal AI helps engineers understand why failures happen and improve decision-making.

Agentic AI takes direct action, adjusting processes autonomously to optimize performance.

In manufacturing, causal AI and agentic AI serve different but complementary roles.

Read the rest of this story at ENGINEERING.com