I had a look at UltiMaker’s new Factor 4 3D printer.

The device is now UltiMaker’s flagship device, overtaking the popular S series. Their remaining MakerBot machine, the Method, seems to be fading away, except for the larger format Method XL model, which is now focused on ABS printing.

The Factor 4 is apparently “built for the factor floor”, as it repeatedly states on UltiMaker’s website. In fact, that was also the first thing I was told when speaking with UltiMaker representatives recently.

But it’s not just a slogan; the Factor 4 has a number of features designed for production use. It is able to handle a wide range of materials, partly because the Factor 4 is capable of higher operating temperatures: up to 340C. The build chamber is now “triple insulated” to capture as much stray heat as possible, helping increase print quality and reliability.

UltiMaker has also ensured reliability through extensive use of sensors throughout the Factor 4. These monitor six different aspects of operation during print operations. Completed jobs get a report on the conditions experienced during the job. For example, the report might indicate that the door had been opened during printing.

The extrusion system on the Factor 4 is a bit different. It’s now a direct drive system, instead of the traditional UltiMaker Bowden approach. This allows the machine to handle a wider range of materials more easily, and in particular flexible TPU.

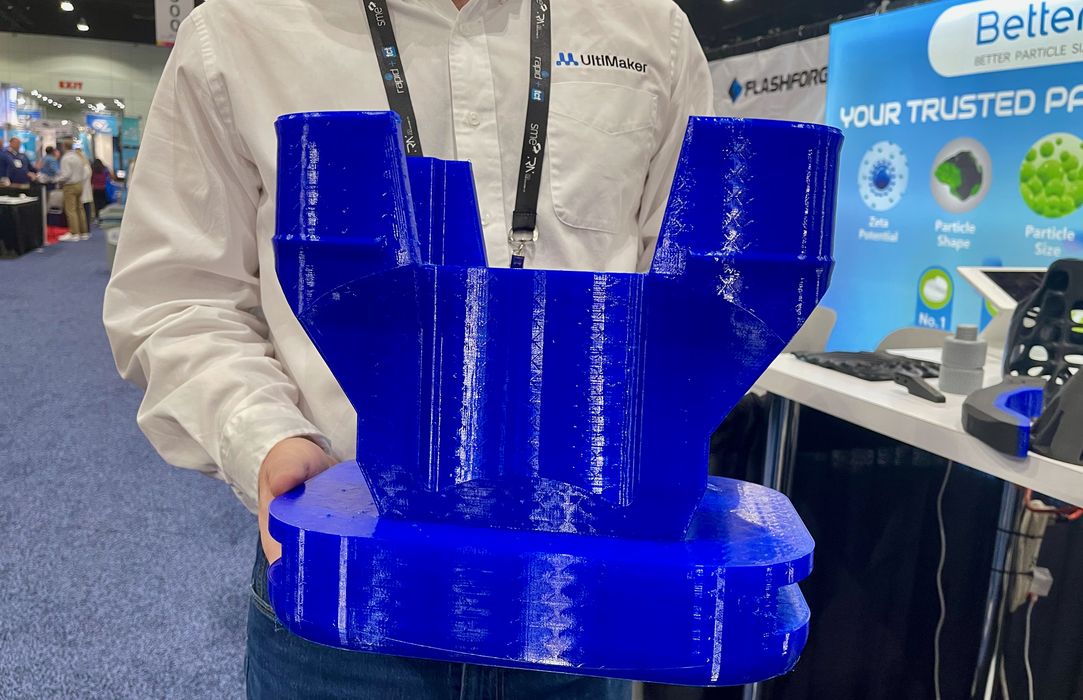

In fact, they say the machine is able to print huge parts in TPU, something that is normally quite difficult to achieve. It was explained that this is partly due to closed loop feedback during printing, and the use of wider 2.85mm TPU filament. They said printing TPU 95A on the Factor 4 is the “easiest ever”. Above you can see an enormous 3D print made only from TPU.

The extrusion system also includes two separate extruders. This permits two materials per job, allowing, for example, use of soluble support material.

However, the separate extruders means there is no waste generated when switching materials during a job. Other multimaterial equipment from competitors in recent times involves purging material every time the material changes. According to the UltiMaker representative, there is “no poop”.

The Factor 4 also can use a PIN for access to the controls, which could be useful in an open factory setting.

UltiMaker isn’t quite shipping the Factor 4 yet, but expects to do so in August. The MSRP on the device is US$19,500.

Via UltiMaker