Ulendo introduced something no one’s seen before: Calibration as a Service, or “CaaS”.

Calibration of 3D printers has long been the domain of the operator, and more recently the machine itself. FFF 3D printers in particular require precise calibration not only to produce good quality prints, but also to work at all.

Bed leveling, Z-gap setting, esteps calibration, temperatures, speeds, input shaping, pressure advance, retraction parameters and many more all can be considered as calibration tasks. Earlier machines required the operator to perform this work manually, while more recent machines increasingly integrate automated methods of doing them.

Now Ulendo shows up with CaaS. How could that work? Does it do all the calibration mentioned above?

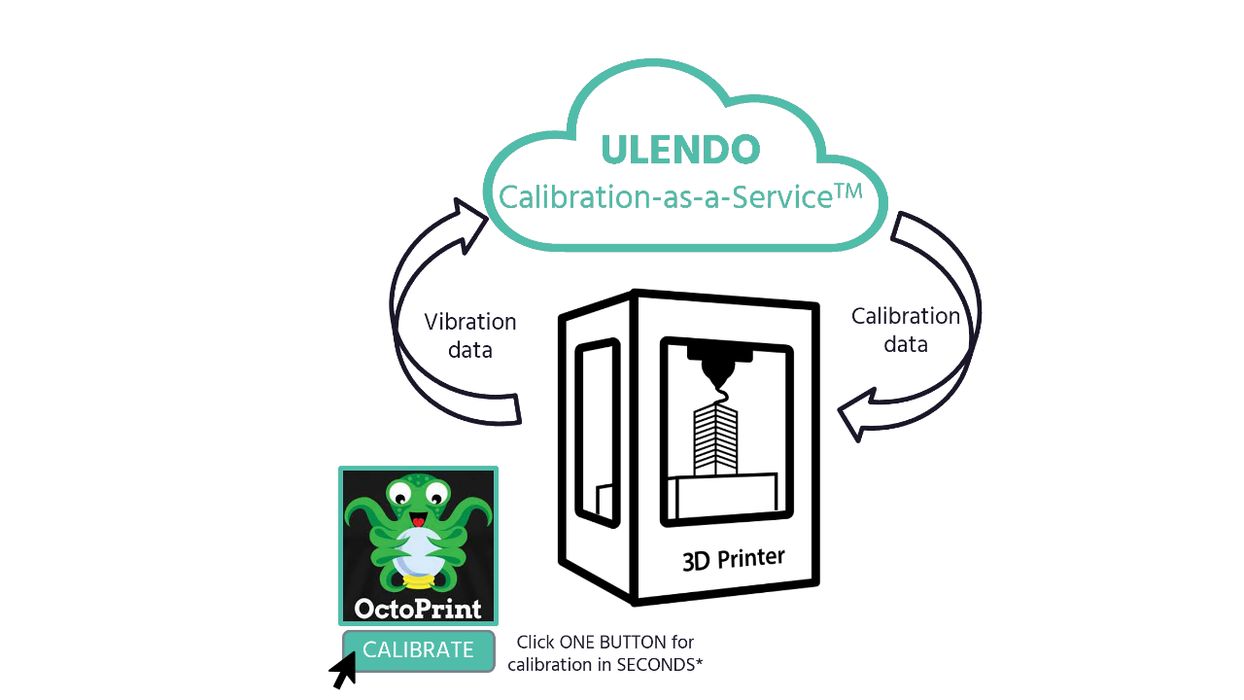

It turns out that CaaS does not do ALL the calibrations, but focuses on the items related to print speed, including input shaping and more. You’ll still have to do several of the normal calibration steps, but Ulendo’s CaaS will handle the vibration compensation automatically. Here’s how it works:

- 3D printers use an accelerometer attached to the toolhead during calibration

- The CaaS plugin is installed to OctoPrint, which runs the 3D printer

- The operator presses a button in the plugin to initiate calibration

- The plugin drives the attached 3D printer through a series of movements and records data, which take only “seconds”

- The data is sent to the CaaS cloud where Ulendo’s algorithms and simulations carefully analyze and produce recommendations

- The recommended parameters are downloaded to the machine

It’s pretty easy: just attach the accelerometer (which can be removed after calibration), and press the button. That’s it!

Ulendo said their calibration process typically enables printers to double their speed from stock firmware and parameters, which is pretty impressive.

The CaaS system works for many types of FFF 3D printers, so long as they have at least Marlin version 2.1 installed.

Is this a free service? Nope, it is not. It’s a subscription-based service, and it seems that the pricing is dependent on a number of factors, such as the number of machines involved, etc. Ulendo said the subscription will cost a minimum of US$275 per year:

“Ulendo Calibration-as-a-ServiceTM is offered as an annual subscription that is tied to a specific individual printer. The annual per printer subscription is based on the number of subscriptions purchased and starts as low as $275.”

With a subscription operators can calibrate machines as often as they wish, even on every job if required.

The US$275, or about US$23 per month, may seem like a steep price for a service that is automatically performed on some equipment. But here remember that this service would work on machines that do NOT perform the calibrations automatically.

Another thought is that by doubling the speed, you are effectively buying another 3D printer: your part production throughput would be twice the original level. Is a second device worth US$275 per year? In many cases, the answer could be “yes”.

Ulendo has plans to expand the scope of CaaS, and we may see them add functionality and printer compatibility in the near future.

Via Ulendo