Ulendo is taking a step into a new set of optimizations: heat compensation.

The startup company is known for their advanced system to compensate for high speed vibrations in FFF 3D printing. Their methods have been adopted by many companies to introduce high speed FFF 3D printers.

While their prime product has been directed towards FFF 3D printing, that isn’t a limitation for the company. Their advanced algorithms can be applied to a number of issues facing the 3D printing industry.

A new product for the company is a method of optimizing heat for LPBF metal 3D printing.

LPBF metal 3D printing might seem to be straightforward: a laser selectively melts fine metal powder on a flat bed, layer by layer. However, it is nothing but simple.

There are massive complications due to the toxicity and explosive nature of the powder. The metal parts being printed are very often end-use production parts, meaning they require very high quality and consistency.

Metal 3D printer operators spend considerable time tuning their print parameters to achieve proper parts, often unsuccessfully. One of the biggest issues is thermal gradients.

The laser melts the metal powder at extreme temperatures, far different than the surrounding material. As the object is built up there are massive thermal gradients between the meltpool and the rest of the object. Heat also travels through the partially printed object and its support structures to make it even more complicated.

There are analysis tools that help identify hot and cold spots for engineers, who can then tweak orientations or support structures to carry more or less heat away from troublesome spots.

But that’s a lot of work and requires highly trained personnel to do the analysis and come up with solutions.

Ulendo turned their algorithms towards this problem and came up with a heat compensation approach for metal LPBF printing.

The idea is to reduce the amount of hot versus cold zones in the print. This is automatically generated based on the material and geometry of the print and its support structures. The result is a thermal profile that is much more homogenous.

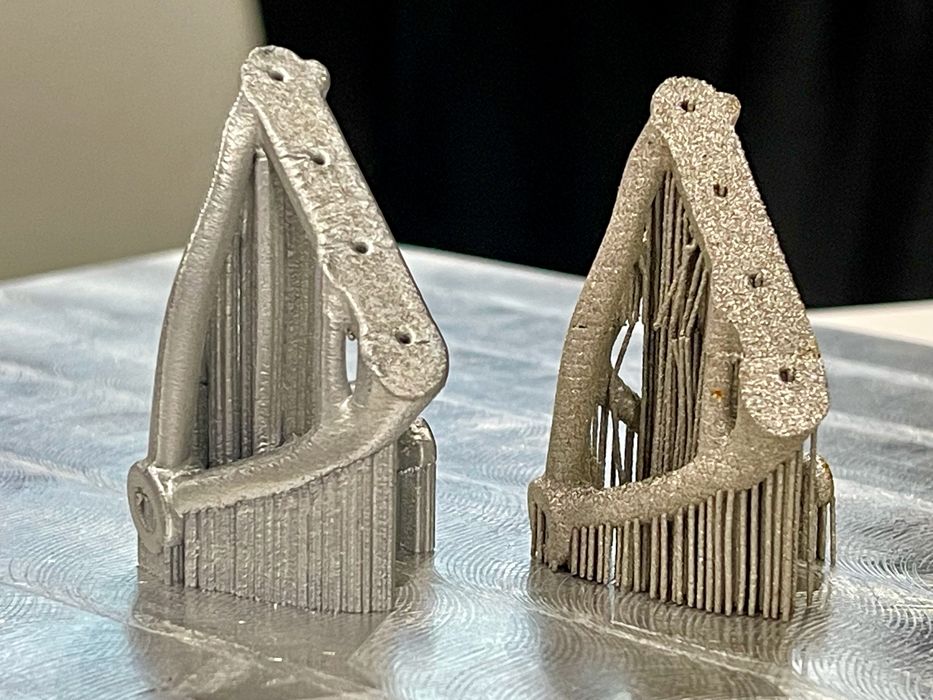

Does this work? Just take a look at the example above of a metal 3D print with (on the right) and without (on the left) Ulendo’s algorithm.

Ulendo is providing this capability via an optional paid plugin to 3D print job preparation software tools. Currently they partner with Dendrite (it’s available as a Dyndrite plugin), but I’m pretty sure there will be further announcements of other partnerships to come.

Via Ulendo