The technology, developed by Mohsen Habibi, holds the potential to repair broken bones without incision.

According to the University of California, Davis (UC Davis), a groundbreaking 3D printing method – developed by Mohsen Habibi, an assistant professor of mechanical and aerospace engineering – holds the potential to repair broken bones without incision.

In a paper published in Nature Communications, Habibi details holographic direct sound printing (HDSP), which uses high-acoustic pressure soundwaves to project a holographic image and remotely print a two-dimensional version of the image in a polymer material like resin. The soundwaves agitated the material, resulting in a solid structure.

HDSP uses an acoustic holographic picture to project and print the whole image at once. A holographic picture, explains Habibi, is simply a 3D volumetric picture of an object (think: Princess Leia appearing to deliver a request for help in Star Wars: A New Hope). While holographic images are typically created with light, Habibi uses an acoustic source to create high-pressure zones within a defined environment.

“With HDSP, I have a hologram that projects a holographic picture of a circle at a certain location,” he said. “That location is inside the build chamber that I filled with material, and it solidifies the picture I want to solidify.”

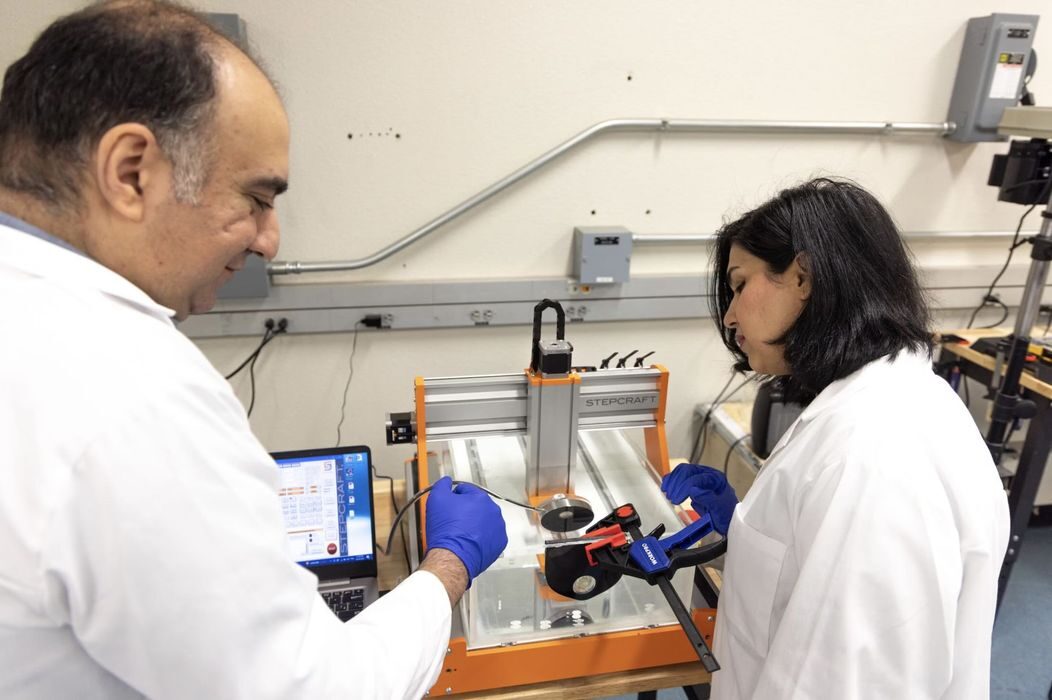

In these experiments, a robotic arm holds the printing platform. The printing platform hovers above the transducer, which is submerged in water. The build chamber sits between the transducer and the printing platform and is filled with polymer printing material.

The transducer emits high-acoustic pressure sound waves – inducing a sonochemical reaction called cavitation, or very tiny bubbles, in the build chamber – creating solid material. The robot arm moves the printing platform along a complex path to create a shape while simultaneously pulling the printed object vertically out of the build chamber – resulting in a 3D structure.

The work builds on Habibi’s previous research in printing with soundwaves for direct sound printing, or DSP, which occurs by applying focused ultrasound waves to a polymer that creates cavitation – resulting in a 3D printed structure.