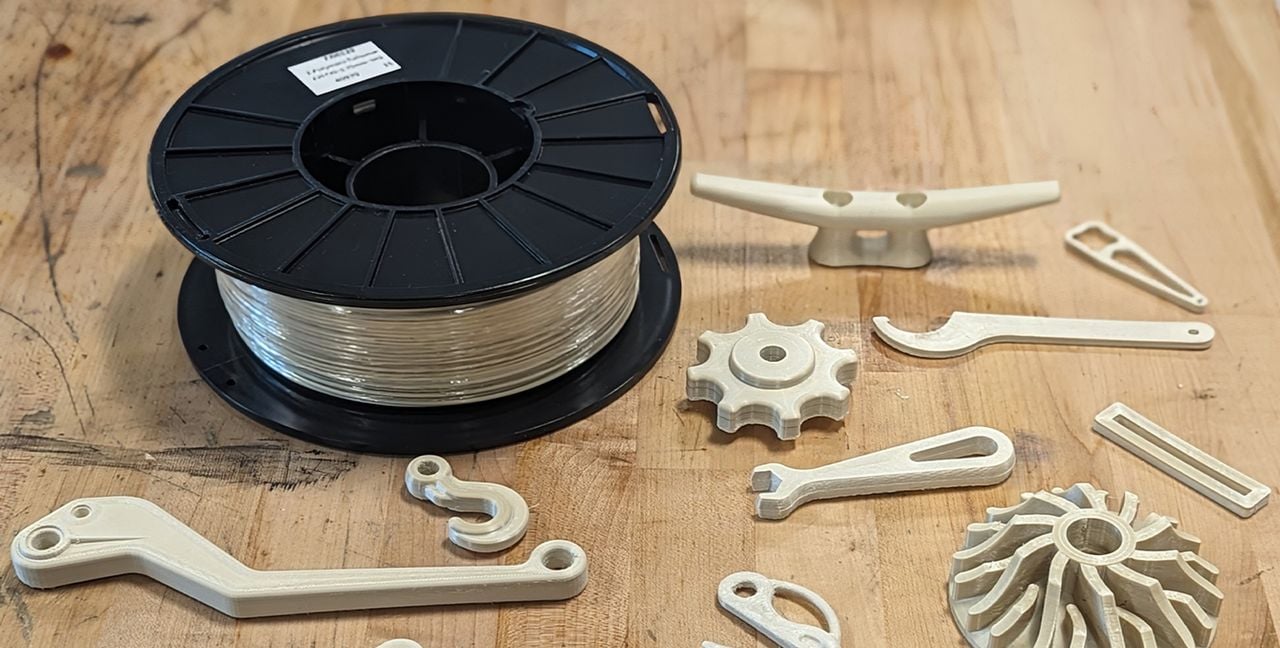

I’m looking at an unusual filament from Z Polymers, Tullomer.

Z Polymers is a new materials company that emerged from the University of Massachusetts’ Lowell Innovation Hub. They produce a monofilament fiber for industry, but more interesting to us is their Tullomer filament for 3D printing.

The Tullomer filament is billed as a “Replacement for aluminum, steel, magnesium, PEEK, PEKK, PAEK, & ULTEM”, which is quite a statement. PEEK in particular has been positioned as a replacement for metal in some low-temperature applications, where its lightweight nature can be an advantage.

How strong is this material? They say it is up to six times stronger than standard 316L stainless steel:

How is this achieved? They explain that the material is fully crystallized, just like metal. This should indeed make the material very strong. At the same time, however, it is also six times less weight than steel, and even lighter than carbon fiber.

Tullomer material is also chemically resistant, radio transparent, non-flammable, heat resistant and doesn’t absorb much moisture. It’s also said to be 100% recyclable, as it is a thermoplastic.

There’s only one place to obtain this miracle material: Dynamism, a US-based 3D printer and materials reseller. There the company offers 500g spools of Tullomer for US$275, or US$500 for a 1kg spool.

That’s pricey, but this is a highly unique material that could be priceless in specific applications.

Can you print this material on any FFF device? Not exactly, as it has some very specific requirements. For example, the minimum possible extrusion temperature is 300C, with 325C being the recommended level. There aren’t many desktop FFF devices that exceed 300C temperatures. The print surface should be 120C or more, and the build chamber’s ambient temperature must be a minimum of 50C.

That may sound unachievable — and it is on many devices — but Z Polymers has figured out a print profile that works on a standard Bambu Lab X1C 3D printer.

They recommend using an adhesive on the bed, such as Magigoo or similar, and not using the AMS filament switching unit. Bambu Lab’s flow dynamics calibration is also not recommended, likely due to the unusual nature of this material.

In the X1C print profile, they run the machine at 300C with 120C on the print surface. This is just within the capabilities of the X1C, and definitely works. Dynamism even sells X1C’s bundled with this filament.

If Tullomer works on the X1C, it’s likely it can also work on other machines with similar characteristics. However, there doesn’t seem to be many print profiles available for this unique material.

Via Z Polymers and Dynamism (Hat tip to David)