Charles R. Goulding and Preeti Sulibhavi discuss how U.S. toy companies are redesigning strategies, diversifying supply chains, and embracing 3D printing to overcome economic uncertainties.

In the U.S., nearly 3 billion toys are sold annually, totaling a massive US$41 billion in retail sales. With 5.5% of all U.S. imports from China consisting of toys and games, the toy industry is deeply intertwined with global trade dynamics. However, proposed tariff hikes on Chinese goods by the Trump administration have sparked significant concerns among potential toy manufacturers and retailers alike.

Hasbro’s Strategic Shift Away from Chinese Imports

The toy industry, which was largely spared during the Trump administration’s first round of tariffs, now faces the potential for greater disruption. However, companies such as Hasbro have already begun rethinking their manufacturing and supply chain strategies, revealing both the challenges and opportunities of navigating an increasingly uncertain trade environment.

Hasbro, one of the largest players in the toy industry, has proactively worked to reduce its reliance on Chinese imports as part of a US$750 million cost-cutting initiative. The company has employed several strategies to mitigate rising costs.

According to Hasbro’s Chief Executive, Chris Cocks, “We’ve [Hasbro] been preparing for many months for any contingency,” related to looming tariffs on China.

Supply Chain Diversification

While China has traditionally been a manufacturing hub for toys, Hasbro has started shifting its production to other countries such as India and Vietnam. By diversifying its supply chain, Hasbro aims to minimize the impact of future tariffs and reduce its vulnerability to geopolitical tensions.

Redesigning Products for Cost Efficiency

Hasbro is also revisiting its product designs to cut costs without compromising quality. For instance, they have explored using lower-cost materials like lighter wood for their iconic Jenga blocks or streamlining production processes for action figures and board games. These adjustments have helped the company remain competitive in the face of rising material and labor costs.

Negotiating Supplier Pricing

To offset higher production costs, Hasbro has been actively renegotiating pricing agreements with suppliers. By leveraging economies of scale and fostering partnerships, the company is finding ways to manage expenses and maintain profitability.

These efforts, coupled with an emphasis on operational efficiency, have positioned Hasbro to manage the potential storm of tariff hikes. However, for the broader toy industry, the stakes remain high as manufacturers explore innovative solutions to stay competitive.

Mattel’s Strategic Moves and Supply Chain Adaptation

Mattel, another heavyweight in the toy industry, has also been proactive in mitigating the risks posed by potential tariffs and supply chain disruptions. The company is adopting a combination of strategic initiatives aimed at reducing its dependence on Chinese manufacturing while exploring innovative production techniques to stay competitive.

Expanding Manufacturing Footprints Outside China

Mattel has increasingly shifted its manufacturing operations to countries such as Mexico, Malaysia, and Indonesia. By spreading its production across multiple geographies, the company minimizes the risks associated with trade tensions, tariffs, and potential logistical challenges tied to a single manufacturing hub. This strategic diversification not only ensures operational continuity but also reduces reliance on any one market for production.

Investments in Automation and Technology

Recognizing the need to modernize its operations, Mattel has invested heavily in automation and advanced manufacturing technologies. This approach has helped streamline processes, reduce labor costs, and maintain product quality. These efforts align with Mattel’s long-term vision of creating a more sustainable and resilient production ecosystem.

Enhancing Cost Efficiency Through Product Design

Similar to Hasbro, Mattel is revisiting its product designs with a focus on cost efficiency. The company has begun experimenting with alternative materials and production methods to maintain competitive pricing while adhering to its high safety and quality standards. For instance, Mattel has explored lightweight plastic composites for toys like Barbie accessories and has simplified assembly processes for complex playsets like its Fisher-Price line.

Sustainability as a Competitive Edge

Another aspect of Mattel’s strategy involves sustainability. The company appeals to increasingly environmentally conscious consumers by introducing eco-friendly materials and packaging. Innovations such as the “Barbie Loves the Ocean” line, made from recycled plastics, not only enhance Mattel’s brand image but also align with broader trends in sustainable manufacturing.

Mattel’s adaptive strategies demonstrate that navigating global trade uncertainties requires a multi-faceted approach. The company is positioning itself as a leader in a rapidly evolving industry by combining supply chain diversification, technological investments, and sustainable practices.

These initiatives also highlight opportunities for broader industry collaboration. As companies like Mattel and Hasbro lead the way in innovation, the toy industry can benefit from shared knowledge and strategies, fostering growth and resilience amid challenging times.

3D Printing: A Game-Changer for Toy Manufacturing in the U.S.

One promising avenue for navigating the tariff challenge is the adoption of 3D printing technology. This cutting-edge manufacturing approach could allow toy makers to bring production back to the U.S., reducing dependency on overseas suppliers and avoiding tariffs altogether.

Benefits of 3D Printing for the Toy Industry

- Cost Efficiency: By using 3D printing, toy companies can produce small batches of toys on-demand, eliminating the need for large-scale inventory and reducing storage costs.

- Design Flexibility: 3D printing enables intricate designs and rapid prototyping, allowing for greater creativity and quicker time-to-market for new products.

- Domestic Production: Manufacturing toys in the U.S. avoids import duties and transportation costs, making it a practical solution amidst looming tariffs.

Examples of 3D Printing in Action

Both Hasbro and Mattel have utilized 3D printing for design for many years; now, it may be the optimal time to incorporate 3D printing into their manufacturing operations:

- Hasbro’s Customizable Play-Doh Sets: Hasbro introduced 3D printed molds for its popular Play-Doh line, allowing customers to create custom designs. This initiative not only showcases the versatility of 3D printing but also enhances customer engagement.

- Mattel’s Hot Wheels Prototypes: Mattel utilizes 3D printing to produce prototypes of its Hot Wheels cars. This enables the company to test new designs efficiently before committing to large-scale production.

- Hasbro’s Action Figure Personalization: Hasbro launched the Selfie Series, where consumers can create 3D printed action figures of themselves. This product highlights how 3D printing can deliver personalized, high-value offerings.

By leveraging 3D printing, toy makers can create a more resilient supply chain while delivering innovative products that resonate with modern consumers.

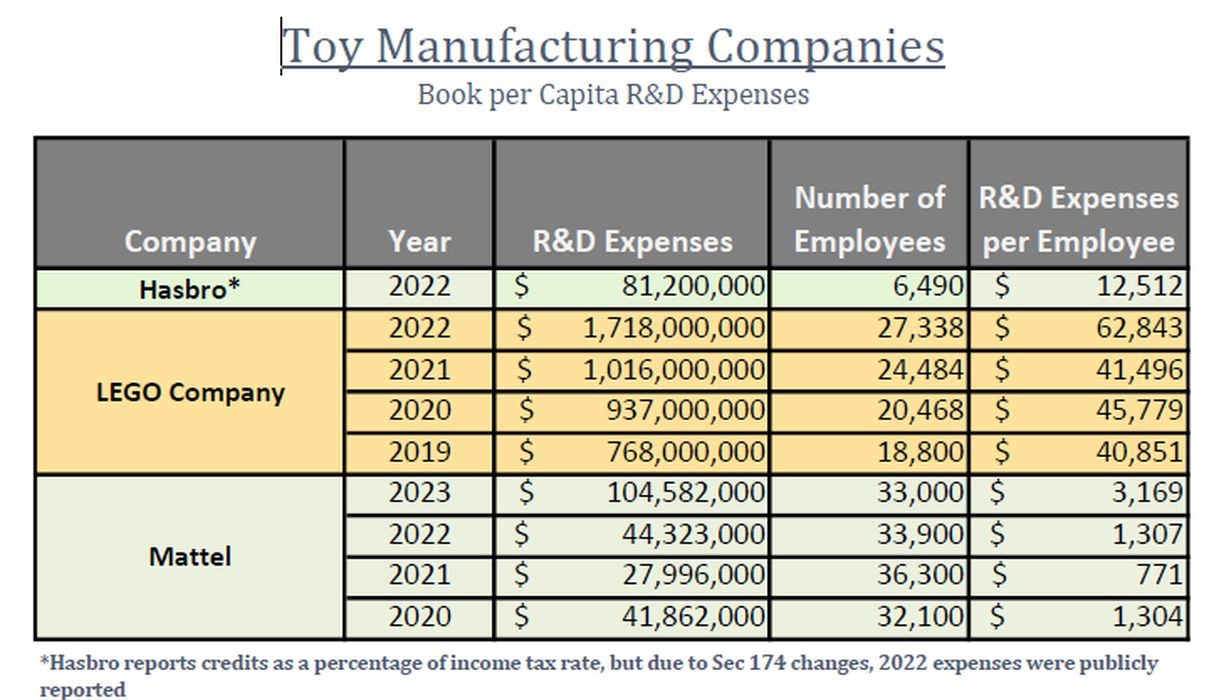

Below is a table that presents the increase in research and development expenditures across three major toy makers in the US.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes are typically eligible expenses toward the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software can also be an eligible R&D expense. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Looking Forward: Building a Resilient Toy Industry

The toy industry is at a critical juncture, facing headwinds from potential tariff hikes and shifting global trade dynamics. However, with strategies like supply chain diversification, cost-efficient design, and the adoption of advanced technologies like 3D printing, companies like Hasbro and Mattel are poised to remain agile and competitive.

As the industry navigates these challenges, the role of 3D printing is likely to grow, offering a sustainable and cost-effective solution for domestic manufacturing. By embracing this technology, the toy industry can continue to deliver joy to millions while staying ahead of economic uncertainties.

After all, in the ever-changing world of toys, the ability to innovate is no child’s play—but with 3D printing, toy makers can be well-equipped to build a brighter future, block by block.