Charles R. Goulding and Andressa Bonafe uncover the health risks of black plastic utensils and explore safer alternatives, including cutting-edge 3D printing technologies.

Recent research highlights the potential health risks of using black plastic utensils, particularly those made from recycled materials. On November 27, the Wall Street Journal published an article entitled “Yes, You Really Should Toss That Black Plastic Spatula” following a series of similar pieces from other news outlets, including The New York Times, CNN, and The Atlantic.

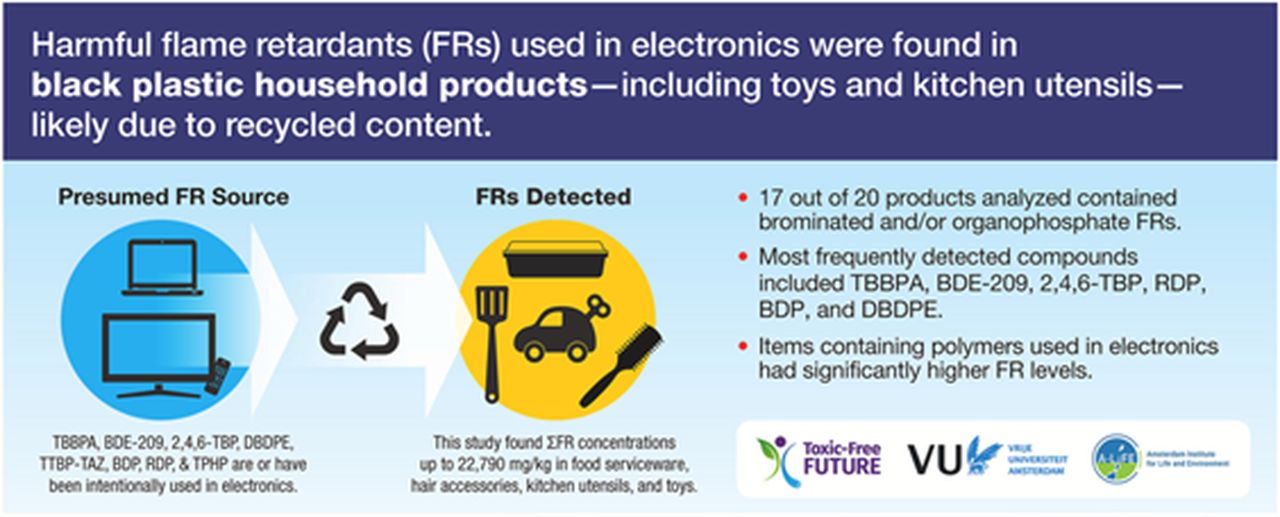

While studies have found that black plastic can contain toxic chemicals like flame retardants, including polybrominated diphenyl ethers (PBDEs), a recent correction highlights that the actual risk to consumers may be lower than initially thought. Although PBDEs are linked to hormonal disruptions, developmental issues, and cancer, the likelihood of significant exposure through the use of kitchen utensils is unclear and may vary depending on specific conditions, such as heat and duration of contact.

Recycled electronic waste plastics are frequently used to manufacture black utensils. While eco-friendly at first glance, the recycling process can unintentionally introduce harmful substances into the resulting plastic material. Heat exposure, especially from hot oils and acids, increases the likelihood of chemical leaching, making black plastic kitchen tools a potential hazard. Experts stress that more research is needed to assess the actual risk to consumers and to shed light on exposure pathways.

Beyond kitchen tools, black plastic has been shown to contain toxic chemicals in items like children’s toys and costume beads. Such contamination highlights broader recycling challenges, as brominated flame retardants bioaccumulate and persist in the body, potentially posing long-term health risks. While researchers remain cautious, they emphasize that exposure from household use likely depends on frequency, type of contact, and specific product composition.

To reduce potential risks from black plastic utensils, experts recommend avoiding prolonged contact with heat, such as leaving utensils in hot pans, and reheating food in black plastic containers. Damaged or chipped items should be discarded to prevent splintered plastic from contaminating food. Replacing black plastic utensils with safer alternatives is also an option. For kitchen items, stainless steel, silicone, wood, and bambooo are durable and non-toxic solutions, each suited to different cooking needs. While stainless steel is highly durable, it can scratch delicate surfaces, making silicone or wood better choices for nonstick cookware. Opting for long-lasting alternatives not only improves safety but also reduces environmental impact, offering a sustainable solution for everyday kitchen tasks.

3D Printing Alternatives

As we look to upgrade our cooking utensils, 3D printing may offer interesting alternatives. Additive manufacturing allows for the production of customized designs tailored to specific needs, offering enhanced functionality and aesthetic appeal. The technology enables efficient prototyping and manufacturing of lightweight yet durable utensils, reducing material waste compared to traditional manufacturing processes.

Considering the food safety of 3D printed items, however, is paramount. There are numerous challenges in using additive manufacturing to create objects that are safe for contact with food. Unsuitable materials, high porosity, particle migration, and potential contamination from various printer components are often listed among the main concerns. Careful adherence to safety standards and processing protocols is essential to overcome these challenges. Experts advise replacing brass parts with stainless steel, using vapor smoothing to fix porosity, paying particular attention to material selection, and performing periodic testing and monitoring. Proper cleaning protocols have also been shown to be effective against contamination.

Sculpteo’s food safety guide lists the following plastic materials as good alternatives:

- PETG (Polyethylene Terephthalate Glycol): Renowned for its strength and durability, PETG is widely used for food-safe applications.

- PLA (Polylactic Acid): This biodegradable and environmentally friendly material is often utilized for crafting food containers and utensils.

- Nylon PA11: A biobased material with excellent mechanical strength and heat resistance, Nylon PA11 is highly recommended for food-contact applications due to its proven safety and reliability.

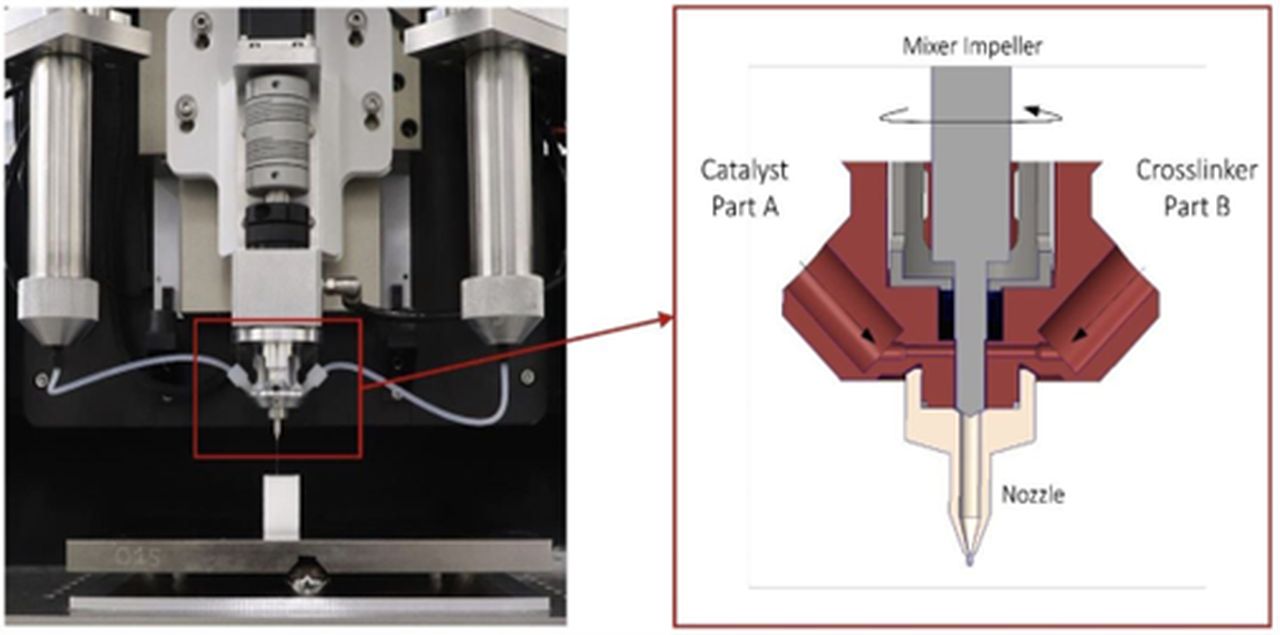

Silicone may also be a promising alternative, particularly with the recent introduction of a new two-part formulation that is transforming the potential for 3D printing with this versatile material. Traditionally challenging due to its slow curing process, silicone often limited printers to simpler designs. Researchers from Lawrence Livermore National Laboratory developed a fast-curing two-part silicone by introducing a catalyst and crosslinker to different parts of the material. When mixed, the two “rapidly rigidize”, forming a solid structure. This innovation allows for the creation of more complex geometries, such as overhangs up to 35 degrees and tall structures with high aspect ratios, all without requiring post-curing or support structures. This breakthrough simplifies printing and expands its applications across industries.

Despite recent developments, there is still significant untapped potential when considering how 3D printed items could replace black plastic utensils. R&D tax credits are available to support U.S.-based companies that engage in this innovative pursuit.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Concerns about black plastic utensils, while tempered by revised scientific findings, still highlight the need for safer and more sustainable kitchen tools. Though the risks of hazardous flame retardants may be lower than previously suggested, experts continue to recommend alternatives like stainless steel, bamboo, and innovative 3D printed materials. With new silicone formulations and food-safe plastics like PETG and Nylon PA11, 3D printing offers tailored solutions to replace potentially harmful utensils. Companies exploring these technologies can benefit from R&D tax credits, encouraging further innovation in safe manufacturing.