Desktop FFF 3D printers don’t last forever — so what wears out?

You’ve just opened up the box on a spanky new 3D printer. It shines brightly on the table, awaiting fingerprints and dust. It will (probably) work very well, at least for a while.

And then things start breaking down.

You will become the maintenance service for your desktop 3D printer. What things might go wrong? Let’s take a look.

Print Plate

That fancy removable PEI spring steel print plate might look invincible, but it’s actually a consumable. As you repeated print on it, each print peels off a few molecules of the coating. After some amount of time you’ll begin to notice gaps in the coating, and that’s clearly time for a replacement.

One strategy I use is to always randomize the location of my prints. Typically slicers place them in the middle of the bed, which then takes the brunt of use. You can easily triple the lifetime of a print plate by randomizing the print location. This is a feature that should be in all slicing software.

Nozzle

The brass (or steel) nozzle of your FFF 3D printer might be made of metal, but it can actually wear out. This is most often due to the use of abrasive filaments that erode the nozzle, but the truth is that everything put through the nozzle can cause some degree of wear.

For a detailed explanation of nozzle wear, see our post from earlier here.

Fortunately, nozzles are (usually) inexpensive, unless you’re operating an unusual FFF desktop device that requires a specialty nozzle/hot end.

A preventive measure you can take is to swap your stock brass nozzle with a much stronger hardened steel nozzle, which are available at pretty decent prices. It’s usually straightforward to replace nozzles.

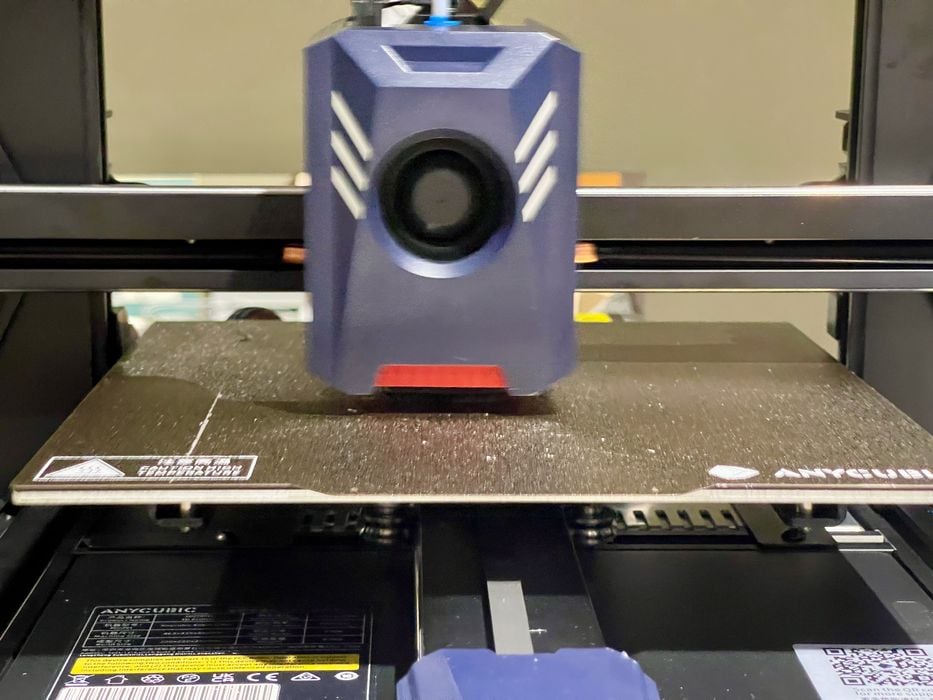

Extruder Gear

Inside your extruder there are a pair of gears (or one on older devices) that grabs the filament and pushes it into the hot end. These gears rotate at just the right speed to extrude the desired amount of material through the nozzle.

However, like the nozzle, these gears are also exposed to abrasive filament materials. Over time these gears can dull and eventually you’ll find they no longer properly grip filament.

Fortunately, this process usually takes quite a long time — unless you consistently print with abrasive materials. Most providers offer replacement extruder gears, and to install them you will have to take apart your extruder. That should be followed by a full recalibration of the device.

But even before the gears wear out, they may accumulate polymer dust, diminishing their gripping power. It’s best to brush out this dust periodically.

Belts

Belts are frequently used in 3D printer motion systems, and especially with the increasingly popular CoreXY system design. Belts are made from strong polymers, but over time and with considerable use they can stretch slightly.

This becomes noticeable when prints have a sudden X or Y axis shift, meaning the belt literally slipped at that point in the job.

The solution is to replace the belt, which can be a complex operation. The process will vary depending on the device, and full calibration will be required afterwards.

Fans

Fans provide important cooling for 3D printers: the extruder must be kept cool from its adjacent hot end, and freshly extruded material must be rapidly cooled, particularly on high speed FFF 3D printers.

However, fans are mechanical devices. Their motors can burn out or degrade. The latter is a more devious situation because the fan might appear to be working, but is actually only pumping, say, 60% of its intended air volume.

Fortunately, fans are usually easy to replace. Most 3D printer manufacturers use standard fan models that are easy to procure, and installation involves a couple of bolts and a pair of wires.

That’s it — while there are many more breakage scenarios possible, these are the primary and most frequently encountered issues of wear.

If you’re 3D printing with an FFF device, you will run into each of these, sooner or later.