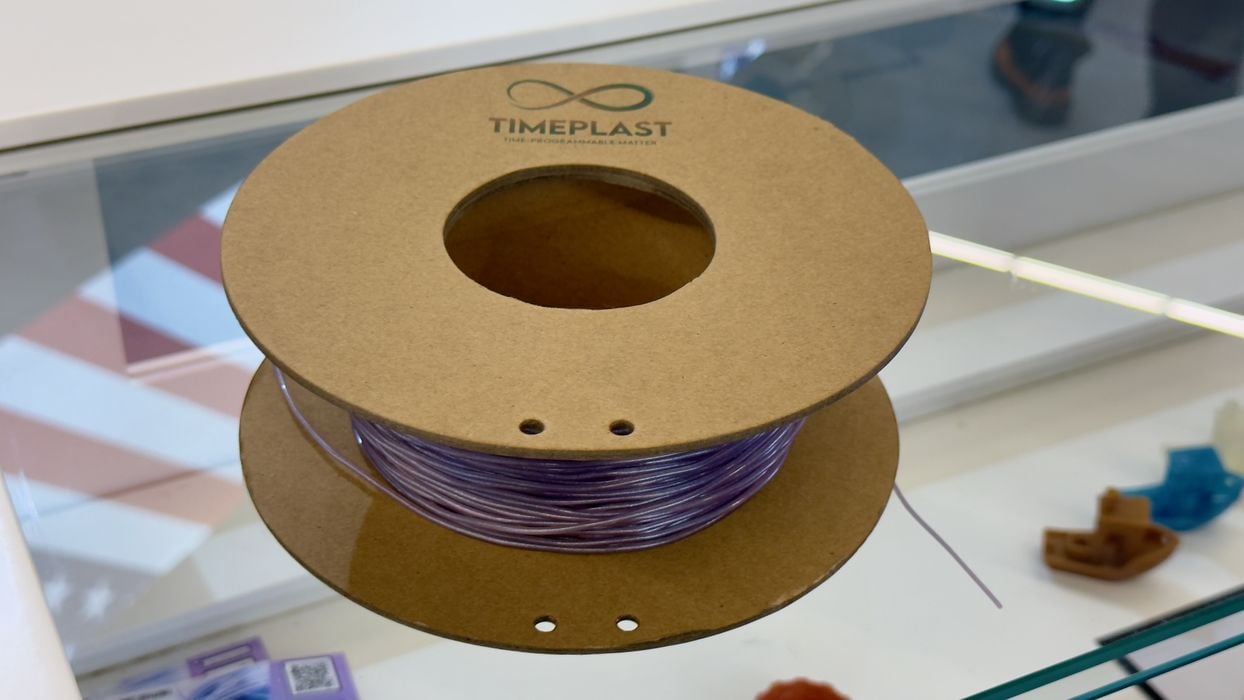

I had a chat with the folks from Timeplast, who produce the most environmentally friendly 3D printer filament ever made.

The company, based in Orlando, has developed a new material — one that’s “not really a plastic” — that can be programmed to dissolve in water on a precise schedule.

They call it a “4D” material because it includes the dimension of time.

What’s it made of? The recipe is obviously secret, but we were told it is based on alcohols and sugars. When dissolved, it leaves “no residue” and is completely benign to the environment. This is something we haven’t seen previously.

In a dry environment, the material is totally stable. But when exposed to water, as it would if thrown away, it begins the process of decomposing with no toxic fumes.

The time factor is apparently controllable during printing by varying print parameters. We weren’t told exactly which parameters, but one can guess it might have something to do with temperatures. They say they have developed print profiles for each “density”.

How could you use this material? Above is an example application. It’s a seed “bomb”. In the inner cavities, you’d place dry seeds and nutrients. The exterior shell of the object is printed so that it will dissolve over the course of a year in the target outdoor area, according to normal rainfall patterns. The interior dissolves faster.

These objects can be printed — with embedded seeds, etc. — and then stored. They are shelf-stable for as long as you need. Then, when ready to deploy, water is injected into them, and they are distributed across the landscape. The seeds sprout and grow inside the shell, much like an egg, and then eventually sprout roots through the decomposing shell. This item provides a near-perfect environment for growing the plants from seeds.

This example application leverages the time dimension in a way that typical 3D prints never consider and brings to mind many other unusual time-based 3D print applications.

They say the material is likely food safe due to the ingredients, so it could also be used as a replacement material for single-use plastics, like straws, deli bags, etc.

They’ve also developed a device called the “PABYSS” to very quickly dissolve the material before its normal decomposition time, if that is necessary. The device uses distilled water to recover the material, which can then be put into a pelletizer and re-used. Losses are said to be “minimal”, and “hundreds of cycles are possible.”

As I listened to the explanation of the Timeplast material, I couldn’t help but think this might be an outstanding replacement material for PLA, used in countless desktop 3D printers.

Desktop 3D prints don’t need programmed water disintegration; they’re almost always dry anyway. This means the prints would be durable — but when thrown away, they dissolve and do not become microplastics. Failed prints and scraps that usually end up in the landfill would simply dissolve. It might even be possible to make a home device to accept them and avoid shipment to waste processing centers altogether.

As for the printing characteristics of this material, it apparently does require a glue stick on print plates, but otherwise should be easily done on most FFF devices.

I’m hoping to test some of this material, and representatives said they would “make us some spools”, which sounds like they are definitely not in production mode at this point. If the material proves effective, we could see them (and maybe others) begin commercialization of this unique material concept.

Via Timeplast