Is it possible to 3D print a #3DBenchy in under one minute? One maker is attempting this feat.

The #3DBenchy model has become the standard item to print and in recent years it’s become the subject of a contest. The idea is to print a #3DBenchy (competently, of course) in the shortest possible time.

But since then machines have increased speed greatly, and today it’s common to buy a new desktop FFF 3D printer that can print a #3DBenchy in 10-20 minutes. In fact, many machines now ship with pre-sliced GCODE to print this famous 3D model.

#3DBenchy first appeared back in 2015, designed by the Swedish firm Creative Tools as a “jolly 3D printing torture test”. Back then a typical 3D printer would take about two hours to complete the little boat.

The ongoing #SpeedBoatRace specifies conditions to participate in the contest, with unofficial results being posted in a Google Spreadsheet. I did an analysis of speed progress last year, when the champion was at only 2:45. Since then it looks like the current fastest #3DBenchy is printed in only 2:19.

The trends showed that the speed curve was converging on just over two minutes, suggesting there would not be any further breakthroughs.

However, that could change with a new project by Jan Roetz of Roetz 4.0.

Roetz is attempting to build a custom 3D printer that could theoretically complete a #3DBenchy in LESS THAN A MINUTE.

Roetz is detailing this design journey through his YouTube channel. So far, two episodes have been published, and he has quite a way to go to complete the design.

Episode 1:

Episode 2:

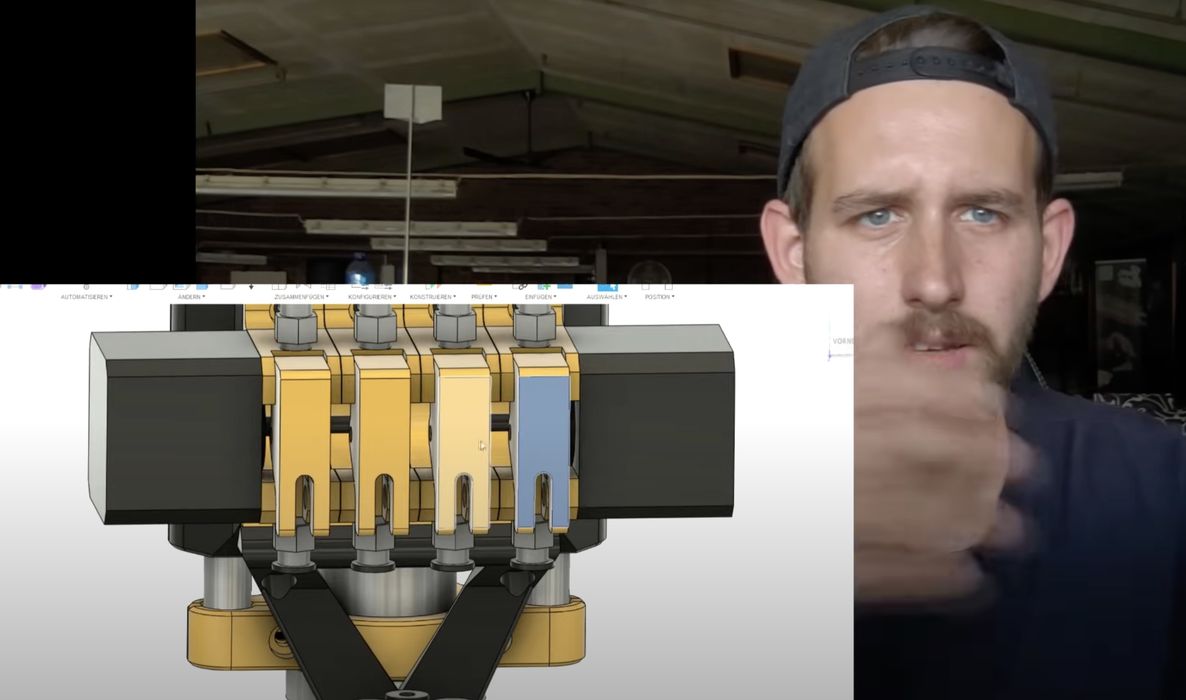

The speed problem is mainly a limitation in the amount of material that can be delivered per second through the nozzle. Roetz’s approach is to deliver a lot more material by feeding the nozzle with FOUR extruders simultaneously, as you can see in the design below.

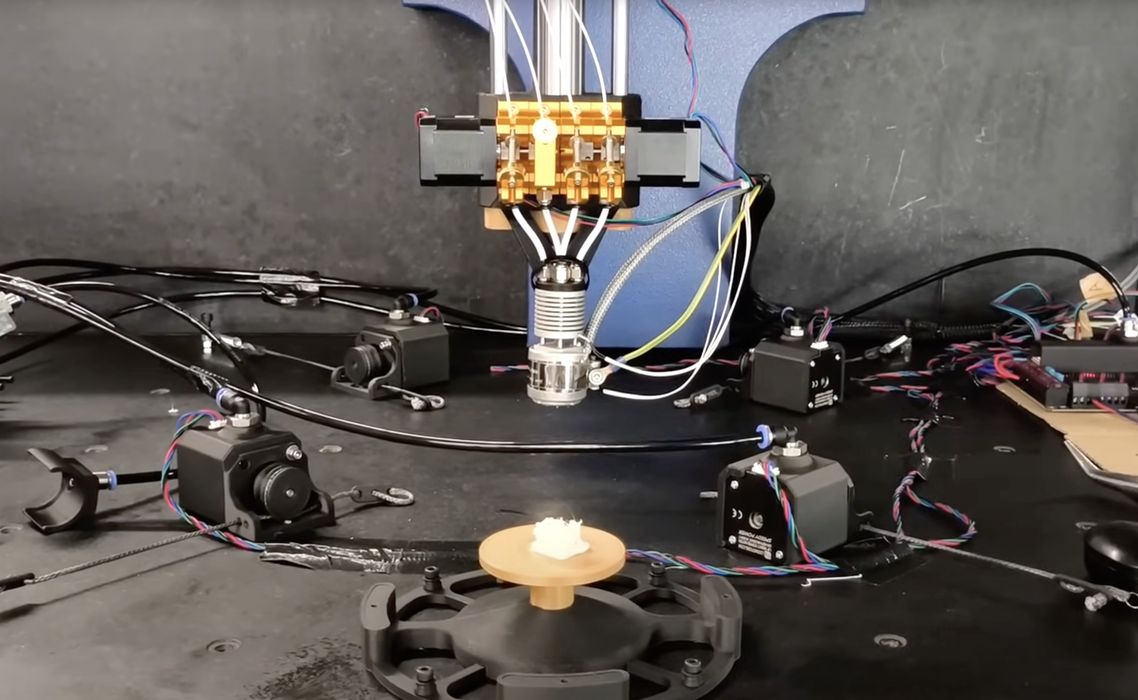

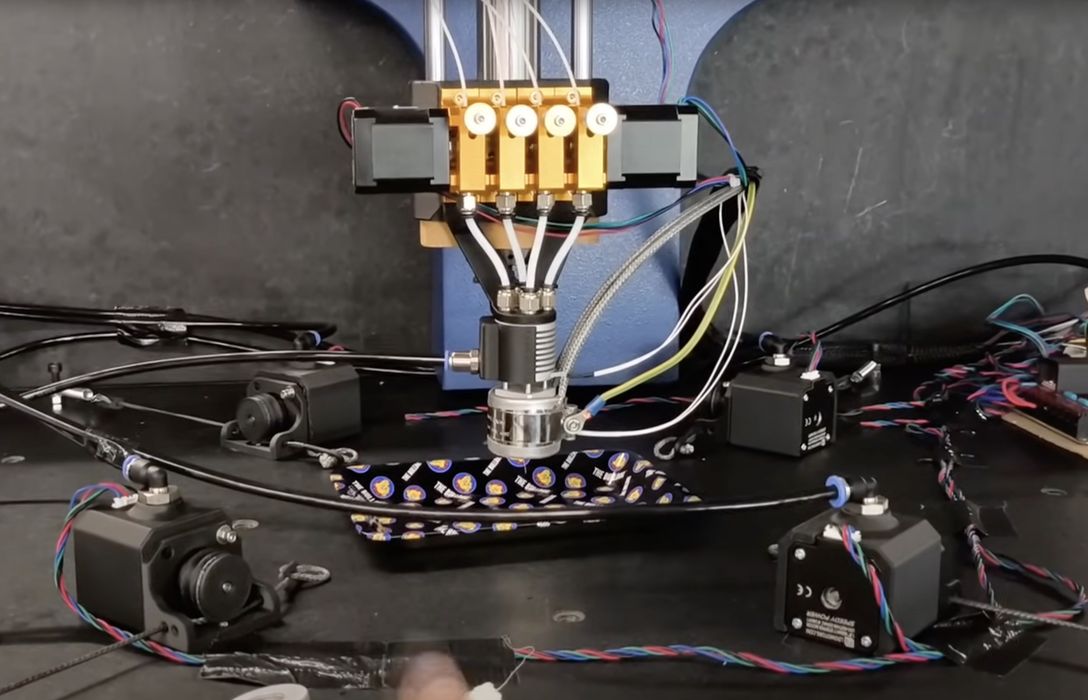

This printhead looks to be quite heavy, and that has caused another interesting twist: the printhead is stationary on the X and Y axes, while the X and Y movements occur in the print plate. The plate is pulled by four motors, as you can see in this image. The Z-axis is implemented by raising the printhead.

This is quite an ambitious project, as Roetz has to custom build many of the metal parts used in the concept. There is plenty of experimentation and tuning yet to occur. In fact, in Episode two an attempt at printing takes place, but is largely unsuccessful.

Will this attempt succeed? We will have to stay tuned to find out.

If it does succeed, it may be that the Roetz machine design might become one that can be used by others. Roetz might choose to open source the design, or license it to companies wishing to build ultra-high speed FFF 3D printers.