Charles R. Goulding and Preeti Sulibhavi explore the growing partnership between nuclear energy, 3D printing, and big tech as companies like Microsoft and Oracle fuel their AI operations with re-commissioned reactors and cutting-edge innovations.

As we enter a new phase of energy production, nuclear power is poised to play a critical role in meeting the massive energy demands of modern technology. The recent deal with Rolls-Royce to develop small nuclear reactors is an exciting step, but large-scale nuclear power plants are still essential for meeting the needs of growing industries, especially in big tech. Companies like Microsoft and Oracle, which require immense amounts of electricity to power their data centers for AI, are directly benefiting from these developments.

The re-commissioning of legacy nuclear plants, such as Three Mile Island in Pennsylvania and Michigan-based facilities, coupled with innovations in 3D printing, is making nuclear energy more feasible and efficient.

Small Nuclear Reactors

The partnership between big tech and nuclear energy is likely to expand as energy demands continue to skyrocket. The re-commissioning of legacy nuclear plants is only the beginning. With companies like Microsoft and Oracle leading the charge, it’s clear that nuclear power will become a cornerstone of powering the next generation of technological innovation.

As Rolls-Royce moves forward with its small modular reactors, the potential for nuclear energy to supply not just tech companies but entire industries is becoming more realistic. These smaller reactors are less capital-intensive and can be deployed closer to where energy is needed, reducing transmission costs and improving efficiency. This is particularly beneficial for data centers, which are often located far from traditional power sources.

The Recommissioning of Legacy Nuclear Plants

The decision to re-commission legacy nuclear plants, including the infamous Three Mile Island and Michigan’s dormant reactors, signals a significant shift back toward nuclear energy. These plants, originally built during the mid-20th century, were designed at a time when 3D printing and other modern manufacturing technologies were non-existent. As they are brought back online, a major challenge involves replacing outdated components—many of which are no longer in production. This is where 3D printing plays a transformative role.

The ability to 3D print nuclear reactor parts is revolutionizing the nuclear industry. While traditionally, creating replacement parts for reactors required complex, lengthy, and expensive processes, 3D printing allows for the rapid production of customized components. With aging reactors like those at Three Mile Island, some parts are decades old and cannot be easily sourced. 3D printing allows engineers to replicate and even improve upon original designs, ensuring these plants can operate efficiently and safely once again.

Big Tech’s Involvement in Nuclear Power

Large tech companies, such as Microsoft and Oracle, are increasingly interested in nuclear power to fuel their enormous data centers, which are essential for artificial intelligence (AI) and cloud computing. Data centers are notorious for their high energy consumption, and as the AI revolution grows, the demand for sustainable, reliable energy sources is rising dramatically.

Microsoft, reportedly involved in the Three Mile Island project, recognizes that nuclear power offers a stable and carbon-free energy source. The company’s AI operations, which require round-the-clock power, could benefit from the steady output of re-commissioned nuclear plants. Oracle, similarly, has explored nuclear power options to meet its data center energy needs, as referenced in recent discussions about nuclear power and big tech collaborations.

With advancements in nuclear reactor design, particularly through the use of small modular reactors (SMRs) such as those from Rolls-Royce, the energy needs of tech giants can be met more efficiently. SMRs provide the benefit of being more scalable and easier to install compared to traditional large reactors, but larger plants like Three Mile Island are still critical for delivering the megawatt capacity necessary to power multiple data centers simultaneously.

The Role of 3D Printing in Nuclear Energy Development

Constellation Energy, Vistra, and Cameco are among the energy companies actively leveraging 3D printing technology to advance nuclear power. These companies are at the forefront of using 3D printing to create components for both existing and new nuclear facilities, demonstrating how far the technology has come since its early adoption in manufacturing.

- Constellation Energy – A leader in the U.S. nuclear energy industry, Constellation has been exploring 3D printing for reactor components that require custom designs or have become obsolete. The company’s commitment to modernizing nuclear plants has included investments in 3D printing for creating complex metal parts used in reactor cooling systems and other critical infrastructure.

- Vistra – Vistra, another major player in the energy sector, has also been incorporating 3D printing in its operations. While the company is more diversified in its energy production, including renewables and nuclear, it sees 3D printing as a way to reduce the cost and time required to maintain and upgrade nuclear facilities. This includes printing parts that might otherwise take months to produce using traditional methods.

- Cameco – Known primarily for uranium mining and fuel production for nuclear power plants, Cameco has been investigating 3D printing technology to streamline its manufacturing processes. By printing parts used in fuel assembly and other reactor components, Cameco aims to enhance the efficiency and safety of nuclear fuel production.

These companies’ adoption of 3D printing shows how the technology is integral to modernizing nuclear power. As nuclear plants age and new reactors are built, the need for rapid, cost-effective manufacturing of complex parts is critical. 3D printing allows for greater design flexibility, making it possible to manufacture highly specialized components with exact specifications.

Advances in 3D Printing Technology: A Complement to Nuclear Power

The evolution of 3D printing technology is a perfect complement to the nuclear industry’s needs. Early 3D printing was limited in materials and precision, but today, advancements in metal 3D printing allow for the production of high-performance components that can withstand the extreme conditions found in nuclear reactors.

One of the key advantages of 3D printing in nuclear energy is the ability to create parts with intricate geometries that would be difficult or impossible to produce through traditional methods. For example, reactor components that must endure high heat and radiation can now be optimized through 3D printing, improving their longevity and performance. Additionally, 3D printing allows for more localized production, reducing supply chain dependencies and lead times.

In the nuclear sector, safety is paramount. 3D printing not only enhances the efficiency of manufacturing but also improves the quality control process. With the ability to produce parts layer by layer, engineers can closely monitor each stage of production, ensuring that parts meet rigorous safety standards.

As we move into this new era of nuclear power, the integration of 3D printing technologies will be essential. Legacy plants can be revitalized, and new reactors can be built more efficiently and safely than ever before.

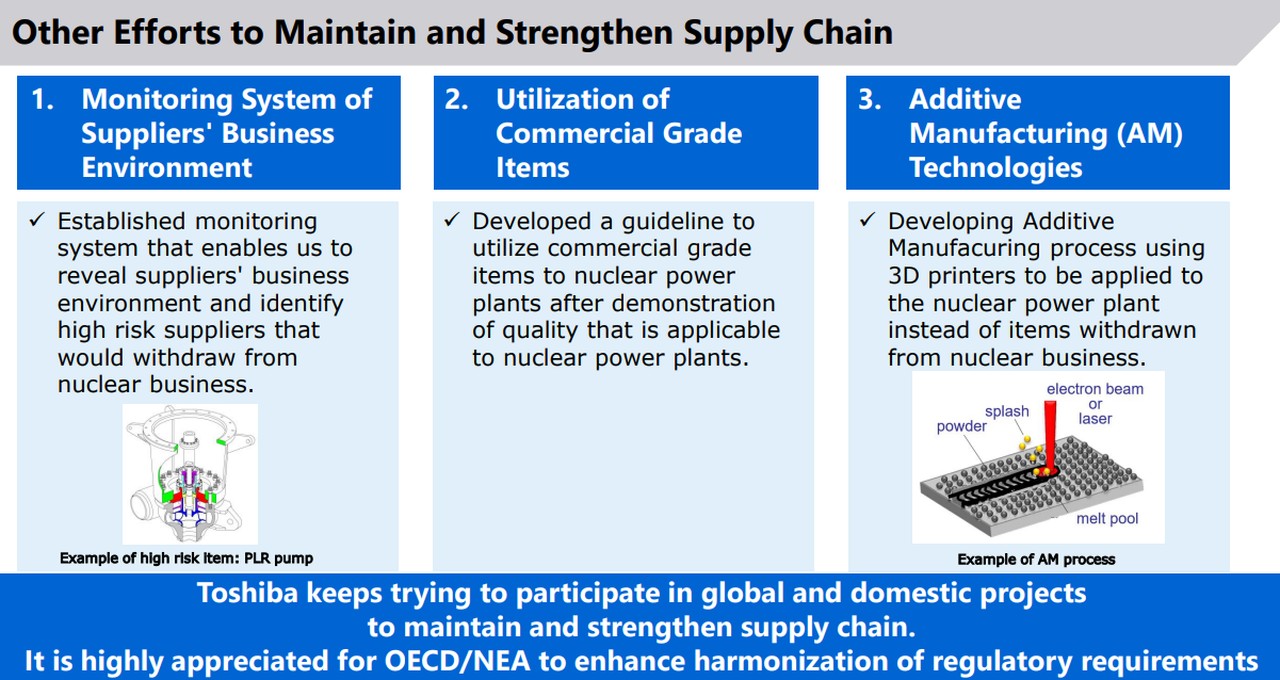

Toshiba presented at the Nuclear Energy Agency’s Multinational Design Evaluation Program’s (MDEP) Fifth Conference in Turkey last year. At that conference, Toshiba indicated that one of the ways in which they are strengthening and maintaining their supply chain is through 3D printing nuclear power plant components on-site, as opposed to replacing items with purchased parts.

The Future of Nuclear Energy and Technology Partnerships

In the US, The Oak Ridge National Laboratory (ORNL) is a leader in nuclear research as well. ORNL has developed a novel method to 3D print components for nuclear reactors and has been licensed by Ultra Safe Nuclear Corporation, or USNC.

The combination of nuclear power and 3D printing offers a glimpse into a future where energy production is cleaner, more efficient, and more responsive to the needs of industries that demand high power levels. From re-commissioning plants like Three Mile Island to building new modular reactors, the nuclear age is poised to make a significant comeback.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The resurgence of nuclear power, bolstered by 3D printing technology, marks the dawn of a new era in energy production. As legacy plants like Three Mile Island and Michigan’s reactors come back online, the ability to manufacture critical components quickly and cost-effectively will be key to their success. Meanwhile, big tech’s reliance on massive amounts of electricity to power AI and cloud computing continues to drive interest in nuclear energy as a stable and sustainable option.

Companies like Constellation Energy, Vistra, and Cameco are leading the way in integrating 3D printing into nuclear operations, creating a symbiotic relationship between these two advanced technologies. As both industries continue to innovate, they are likely to shape the future of energy and technology for years to come.