A Swedish startup is developing a unique glass 3D printing technology.

Glass 3D printing is not common, as it is extremely challenging. Melt temperatures for glass material are vastly higher than polymers and even metals, and require very different hardware.

It’s so difficult there have been very few commercial attempts to produce a glass 3D printer, although there have been many research experiments. Previously, we’ve seen these:

- Glassomer offers a resin that can be 3D printed into glass objects with specific post processing steps

- Micron3D announced a glass 3D printer in 2017, but it doesn’t seem to be offered anymore

- Lios Design announced a glass 3D printer, but their website no longer exists

- Sygnis offers the SYGLASS2 glass 3D printer, but it seems to be mostly used for fiber optic cable production

- Maple Glass Printing offers the Maple 3, an FFF-like glass printer that prints in very coarse layers

And that’s all we are aware of, so you can see that this is not a busy space in the 3D print world.

The new entrant is Nobula3D, based in Stockholm. They’ve developed what they call DGLD, or “Direct Glass Laser Deposition” technology. They don’t describe or show how this works. They do say that they have a “unique glass filament” of a patent pending design. Their system can print at temperatures between 400-2200C, far hotter than any FFF device.

Putting this all together, it would seem that they have a toolhead that extrudes a glass filament, which is then struck by a powerful laser that instantly melts the material. An undescribed motion system moves the toolhead in 3D space, allowing the production of 3D objects.

This is similar to DED-style metal 3D printing, where a welding wire is heated by a laser. While DED only allows for very coarse layers, DGLD is different in that it can achieve layer sizes of only 0.100mm. That’s comparable to many FFF 3D printers, and therefore one can expect similar part quality.

Nobula3D lists the print speed as between 5-200mm/s, which is pretty slow compared to FFF devices. However, remember you’re printing glass here, something impossible on other equipment.

We don’t know the build volume of the glass 3D printer, but the exterior machine dimensions are 1000 x 400 x 600 mm. With some insulation for the tremendous heat we could expect a build volume of something less than 200mm on a side.

More interesting tidbits: post processing is “not required”. I’m not sure what that means regarding support structures. Surely support structures can be printed? Or does their motion system involve multiple axes that would rotate the print around to avoid support structures? We won’t know until Nobula3D shows us a bit more about their technology.

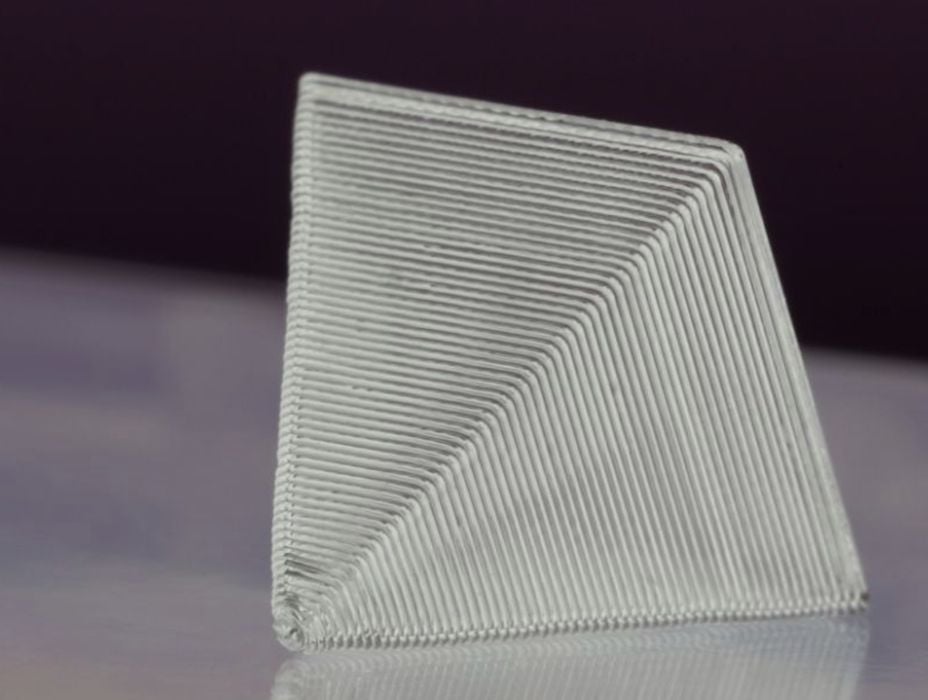

What we have here seems to be a very capable glass 3D printer that can print objects similar to what you’d get on common polymer 3D printers. In other words, more advanced geometries. Most of the prior glass 3D printing processes had severe limitations in geometry because glass tends to cool slowly and slump. That doesn’t seem to be case with Nobula’s DGLD for some reason.

We can infer this from looking at the print samples shown above.

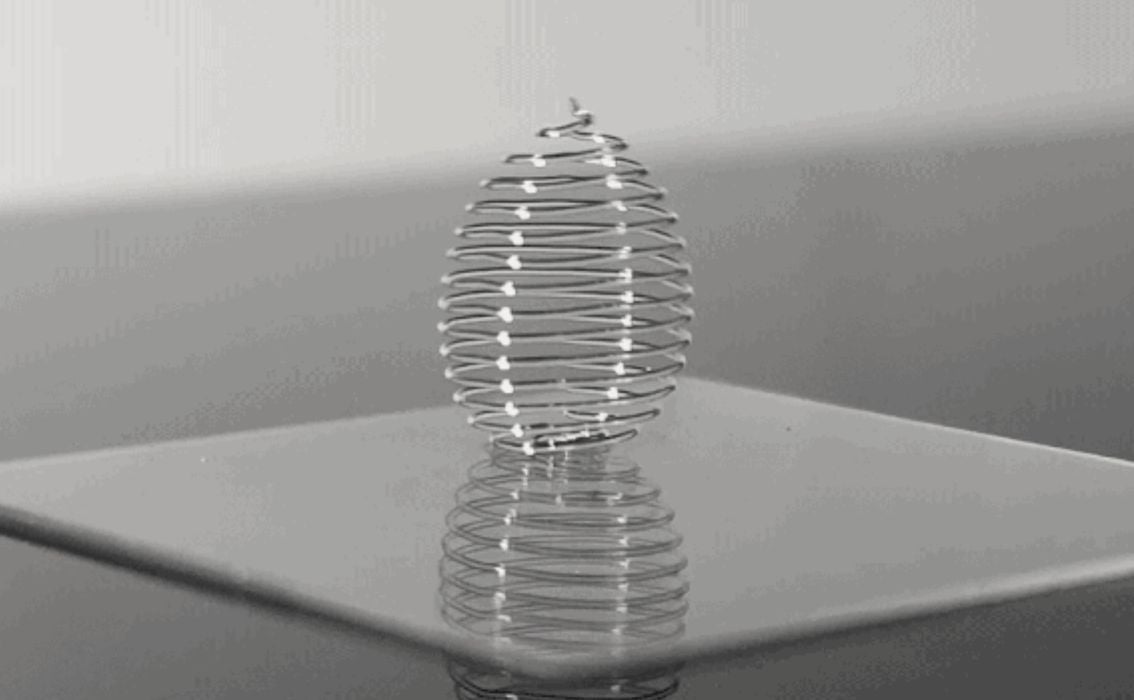

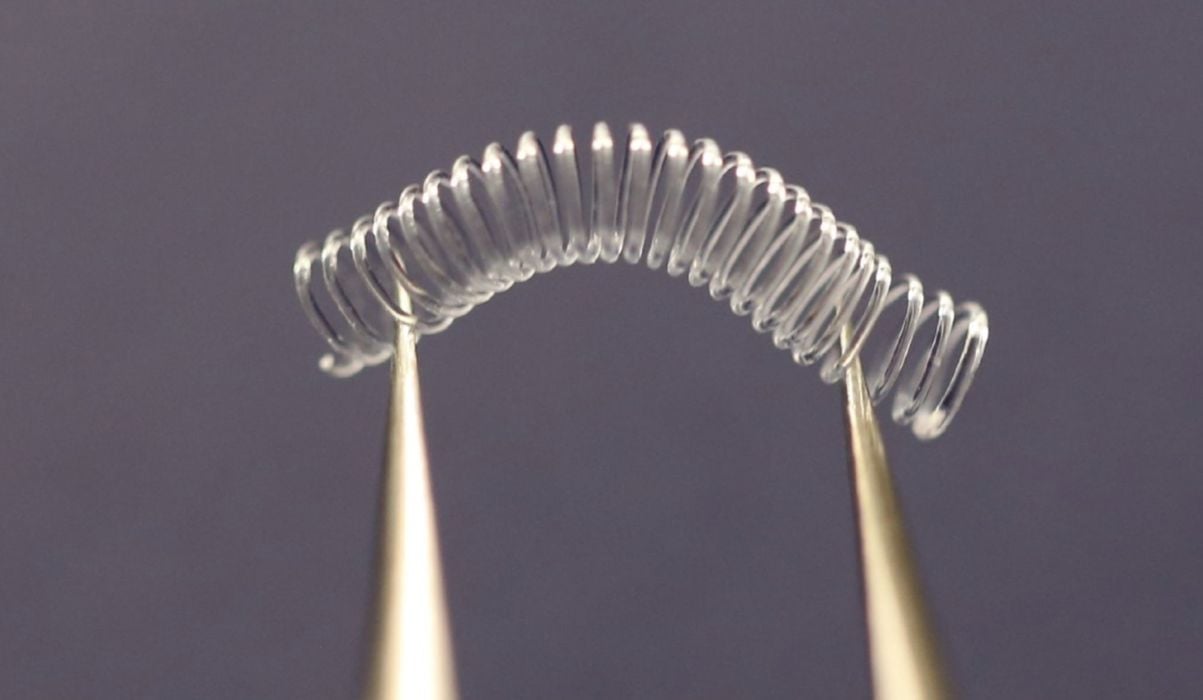

One extremely interesting example print that demonstrates the capabilities is this glass spring. A spring made from glass? Yes, it’s possible as the glass does have some flexibility, and adding many circuits can provide enough total give to act as a spring.

Here’s the really interesting part: glass has very high thermal resistance, making this spring functional at blistering temperatures up to 1000C. That’s an application no one has envisioned, and shows the challenge facing Nobula3D: finding the right application niche.

Like most new technology companies, it seems that Nobula3D is at that stage where they are trying many different applications in a search for the best option. Example prints shown include microfluidics, optics, filters, medical, art, packaging, polishing, anti-counterfeit and many more. These are all wildly different applications, and it’s not known yet which ones will stick.

I’m quite interesting in following Nobula3D’s progress, as they seem to have one of the most promising methods of 3D printing glass yet seen.

Via Nobula3D