Supernova has finally unveiled the materials for use in their VLM system.

Supernova, if you recall, is a spin-off of Spain-based BCN3D. While BCN3D has focused on FFF 3D printers, they also developed a unique resin-based printing technology they call “Viscous Lithography Manufacturing”, or “VLM”. The technology was so powerful that they spun off a second company to handle it, Supernova, about a year ago.

VLM differs from other resin processes as it is able to handle far more viscous resins. This is quite important because the engineering properties of a resin are largely determined by the additives used — and some additives make resins quite viscous.

Typical resin 3D printers are unable to handle viscous resins due to mechanical and flow issues. For example, MSLA devices require resin to flow by itself into voids on each layer, which would be interminably slow with a viscous resin. Because of this effect, most resin 3D printers are only able to print objects in relatively fragile materials.

When VLM was announced, it appeared quite promising — but there was little mention of the materials. That’s likely because there weren’t any viscous 3D printer resins on the market: no machines could print them. Supernova has spent the better part of a year developing a set of VLM-compatible resins, and now they’ve announced a large set of them under the “Viscogel” brand.

In their press release, Supernova describes over a dozen different Viscogels and variants. They include analogs for rigid composites, ductiles, rubbers, and silicones, quite a range of properties. They also provide some with ESD and FR variants.

This is quite a feat: in one swoop, Supernova has created a very broad portfolio that instantly enables countless applications in many areas. This is quite different from typical new technology launches, where you have to wait months for each new material type. Here, Supernova is ready to market to almost any manufacturer.

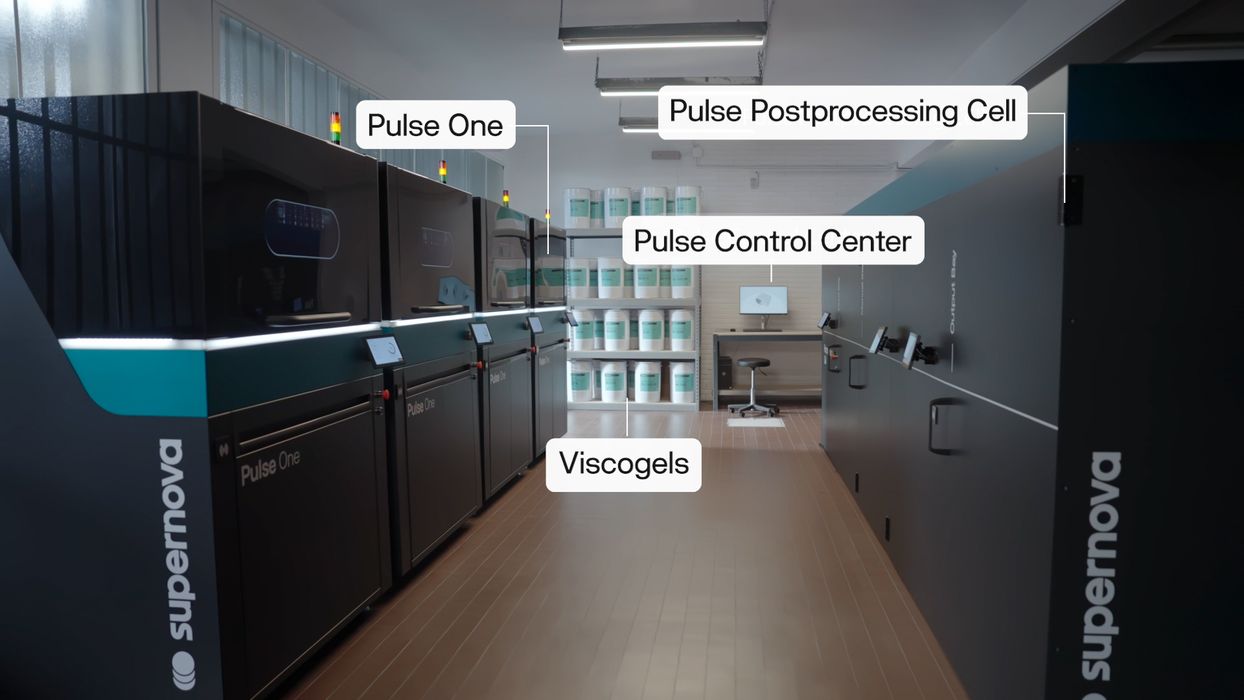

They also announced a new production platform, which complements the new Viscogels quite well.

The “Pulse Production Platform” is Supernova’s end-to-end solution for manufacturing. With a build volume of 340 x 200 x 300 mm, the Pulse One is able to print up to 5kg of materials per hour, which is significant. Designed for 24/7 operation, the Pulse One could be an ideal solution for some manufacturers.

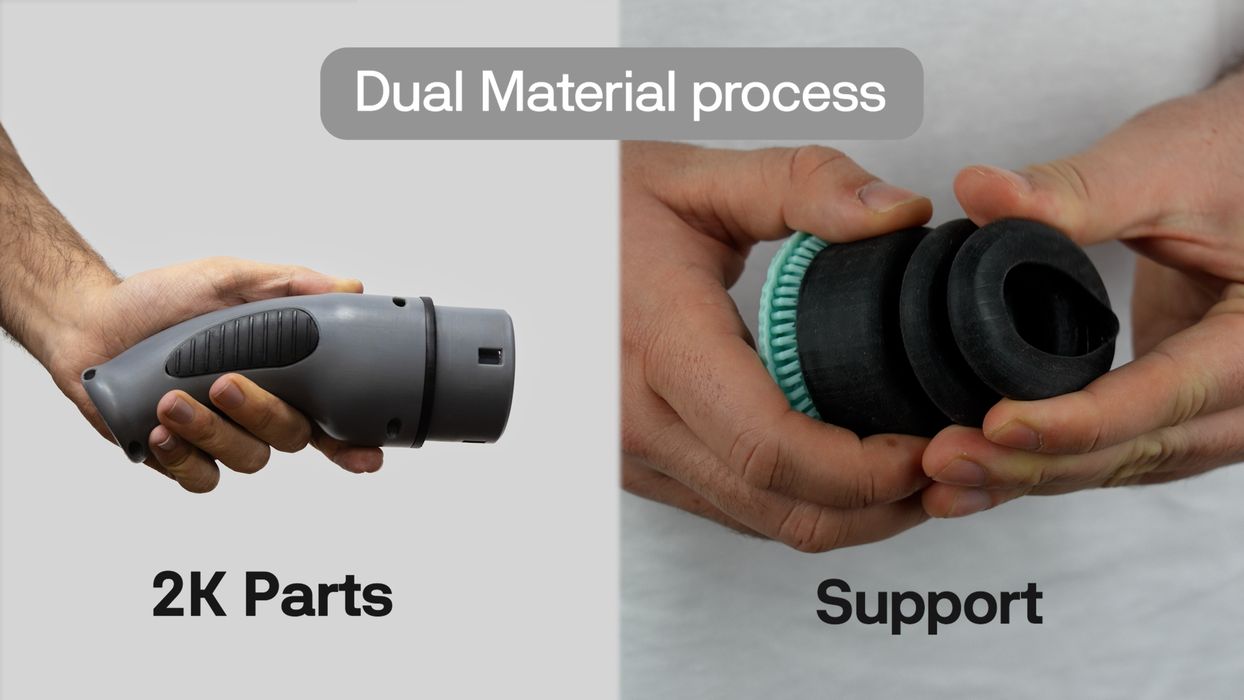

One surprising feature of the Pulse One is that it is a dual-material device. Supernova explained:

“Pulse One offers dual-material capabilities, enabling the simultaneous use of two different materials for production of 2K parts or the use of a secondary support material.”

And:

”The first, known as 2K, allows the construction of parts using two different materials simultaneously. This means users can seamlessly combine rigid and elastomeric materials within a single build, unlocking the ability to create functional multi-material components without the need for costly overmolding tools. For example, Pulse can produce rigid connectors with elastomeric seals manufactured in place. Building parts in 2K with VLM offers unprecedented design freedom while also reducing production costs and lead times compared to traditional plastic molding methods.”

There’s even more: Supernova also announced a post-processing system for the Pulse One, the Pulse Postprocessing Cell. The Cell provides washing and curing functions, and can cycle through a job in an hour, meaning it can handle 24 builds per day. Supernova described the cell as completely automated, which should result in highly consistent part quality.

The Pulse Production Platform also makes heavy use of RFID technology as jobs pass through the various stages of processing. This enables the system to keep track of operations in some detail, and provide complete traceability for applications that require it.

This is an incredibly impressive announcement, as a very complete manufacturing system has suddenly appeared on the scene. Is there a catch? Well, yes, there’s one: the system and materials aren’t shipping until “fall 2025”.

We’ll have to wait a while to see VLM in production use, but I’m sure there will be many customers interested in this system.

Via Supernova