Stratasys launched a new 3D printer and at the same time increased the resolution on all their SAF 3D printers.

Stratasys is perhaps best known for their FDM (FFF) 3D print technology, but in recent years they’ve undergone quite a bit of diversification. They’ve developed or acquired multiple different 3D printing processes to address wider markets.

One of their main non-FDM technologies is SAF, “Selective Absorption Fusion”, which they announced back in 2021. If you’re not familiar with SAF, here’s a quick rundown:

- In the build chamber, a layer of polymer powder is laid down flat

- A printhead sweeps across the powder bed, selectively depositing fluid droplets where solid material is required

- This fluid (HAF) is designed to quickly absorb energy and release it as heat

- A second sweep across the partially wet print surface emits infrared radiation

- The HAF-wet portions heat up rapidly to the point where the surrounding polymer powder melts and then solidifies

- The process repeats, layer by layer, until the object is complete

There are some tremendous advantages to SAF, including the ability to scale up to large volumes, extremely rapid printing, precise thermal control, no need for support structure (powder does that for you), and full 3D volume printing capacity.There are some tremendous advantages to SAF, including the ability to scale up to large volumes, extremely rapid printing, precise thermal control, no need for support structure (powder does that for you), and full 3D volume printing capacity.

Stratasys announced the first SAF device, the H350 shortly thereafter. Now it seems that they’ve upgraded the H350 into the H350 Version 1.5.

The new H350 includes a number of improvements, including additional real-time sensor and remote service capabilities.

But the big new feature is increased resolution provided by the Stratasys HighDef Printing firmware update. How precise is HighDef? Well, we actually don’t know, since Stratasys has not appeared to have published any specifications. However, they say this:

“This innovative SAF firmware upgrade enables users of the H350 to achieve the industry-leading narrowest gap clearance within the area-wide powder bed fusion sector. This refers to the smallest possible spacing on surfaces that prevents them from fusing together, thus ensuring precise and tight fits in mechanisms and assemblies.”

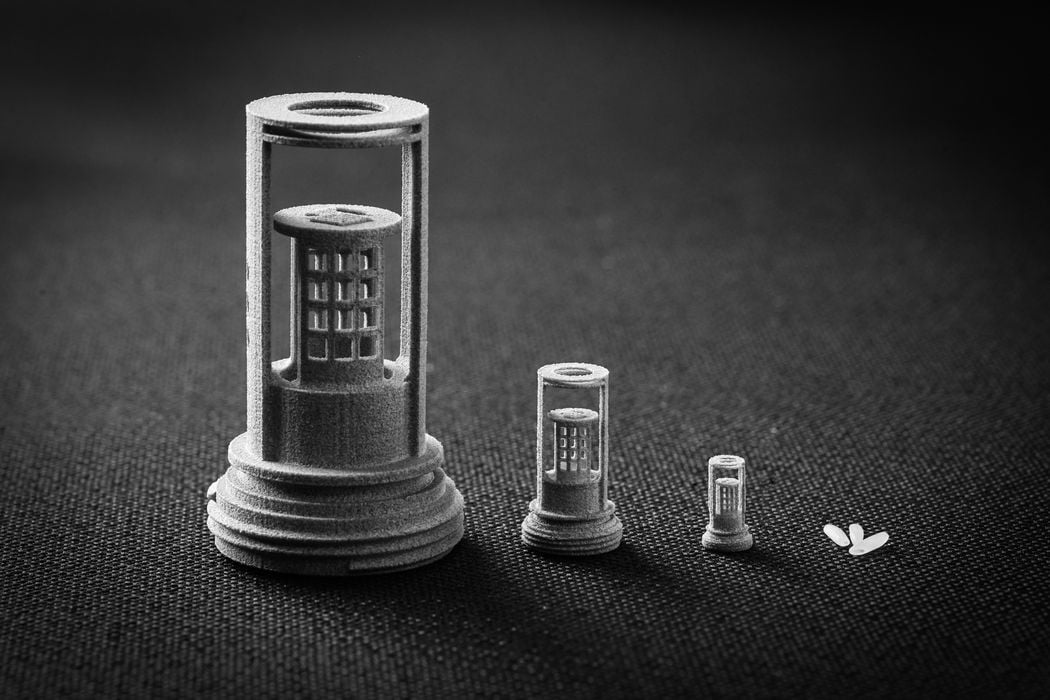

In this image we can see that the H350 V1.5 is cable of producing quite high resolution prints, but again, there’s no banana on the image to indicate the scale.

Regardless, it’s obviously better than before, and should be of interest to those using the H350 for production, which is the target market for SAF. It’s able to produce large quantities of parts at relatively low cost and print durations. The additional resolution means these systems can be used to produce more types of parts that were not previously possible on the older H350.

But wait, there’s more.

It turns out that the firmware update is being provided to ALL H350 systems. This means that every H350 will be HighDef capable, and also implies that the increased resolution was not achieved by installing newer inkjets with tighter nozzles.

These changes should make SAF more attractive for industry.

Via Stratasys